-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

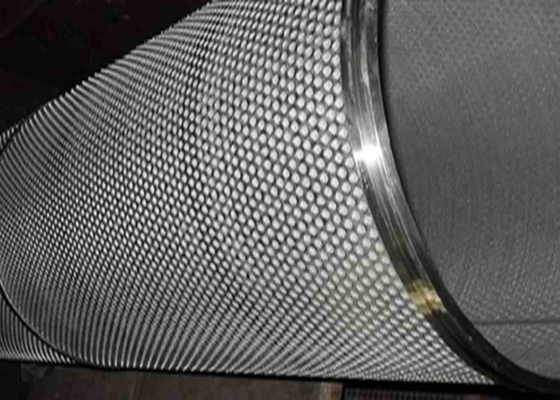

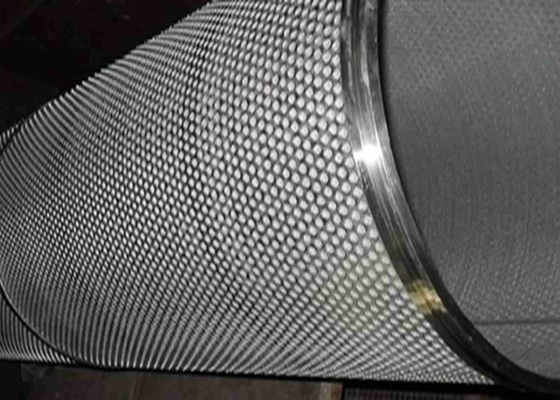

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Stainless Steel Plain Weave Sintered Wire Mesh 5 To 7 Layers Up To 480℃

| Packing | Carton, Wooden Case, Etc. | Weave Type | Plain Weave, Twill Weave, Dutch Weave, Etc. |

|---|---|---|---|

| Width | 0.5-2.5m | Mesh Count | 2-635 Mesh |

| Length | 10-100m | Edge Treatment | Cutting, Rolling, Etc. |

| Material | Stainless Steel, Low Carbon Steel, Copper, Aluminum, Etc. | Aperture | 0.02-20mm |

| Highlight | plain weave sintered wire mesh,7 layer sintered wire mesh,stainless steel 5 layer sintered mesh |

||

Product Description:

Stainless steel sintered wire mesh has high mechanical strength and superior corrosion resistance to fit various applications. The most common sintered stainless steel wire mesh is sintered by 5-7 layers SS wire meshes.

Raw materials: SS316L, SS304, duplex SS, super duplex 2507 …

Temperature: up to 480℃

Common layers: 5-7 layers

Features:

Stably filtration precisionby consistent pore size

Superior pressure resistance as stainless steel construction

Prominent oxidation& rust resistance for corrosive condition

Uniform pores distribution for excellent permeability

stainless steel sintered wire mesh is resistant to high temperature, for example, 5-layer SS sintered wire mesh can withstand up to 480℃. Meanwhile, Filson SS sintered wire mesh is made of 904L or super duplex 2507 can operate normally in high acid and alkaline environments.

Technical Parameters:

| Parameter | Value |

|---|---|

| Wire Diameter | 0.02-2.03mm |

| Material | Stainless Steel, Low Carbon Steel, Copper, Aluminum, Etc. |

| Aperture | 0.02-20mm |

| Features | High Strength, Corrosion Resistance, Etc. |

| Shape | Roll, Sheet, Plate, Etc. |

| Mesh Count | 2-635 Mesh |

| Application | Filtration, Sieving, Grading, Etc. |

| Edge Treatment | Cutting, Rolling, Etc. |

| Packing | Carton, Wooden Case, Etc. |

| Thickness | 0.02-2.03mm |

| Weave | Square Weave |

| Rating Range | 1 to 100 Micron |

| Type | Sintered Woven Wire Mesh |

Applications:

can produce stainless steel sintered wire mesh in various raw materials, such as SS 304, SS 316L, SS 904L, duplex stainless steel, and super duplex 2507. It is widely applied in the petrochemical, metallurgy, and pharmaceutical industries.

Customization:

Brand Name: QIANPU

Place of Origin: ANPING

Length: 10-100m

Application: Filtration, Sieving, Grading, Etc.

Edge Treatment: Cutting, Rolling, Etc.

Width: 0.5-2.5m

Features: High Strength, Corrosion Resistance, Etc.

Special Feature: Square Weave, -200°C to 600°C

Support and Services:

We provide technical support and services for Sintered Wire Mesh products. Our team of experienced engineers is available to assist customers with their product needs and questions.

Our engineers are available to answer any technical questions you may have about Sintered Wire Mesh products. We can help you understand the product specifications and performance, as well as provide guidance for product selection and installation.

We also provide product service for Sintered Wire Mesh products. We can help with product installation, troubleshooting, and maintenance. We also offer replacement parts for our products.

Our customer service team is available to answer any questions or concerns you may have about our products. We are committed to providing excellent customer service and support.

Packing and Shipping:

Sintered Wire Mesh packaging and shipping involves careful coordination of all the necessary steps for it to reach its destination ely and in a timely manner. The materials used for packaging must be able to withstand the pressure, temperature, and other environmental conditions during shipping. The packaging must also be able to protect the product from outside contaminants and provide the necessary protection during transit. For Sintered Wire Mesh, the packaging and shipping process typically involves the following steps:

- Inspection of the product – to ensure that it meets quality standards and is free from defects.

- Wrapping and packaging – using materials such as foam, bubble wrap, or shrink wrap, to protect the product from damage during shipping.

- Labeling – to provide information about the product and its destination.

- Shipping – to ensure that the product arrives at its destination in a timely manner.

FAQ:

Q1: What is sintered wire mesh?

A1: Sintered wire mesh is a type of mesh made by sintering, which is a welding process used to bond multiple layers of metal mesh together.

Q2: What is the brand name of the sintered wire mesh?

A2: The brand name of the sintered wire mesh is QIANPU.

Q3: What is the place of origin of the sintered wire mesh?

A3: The place of origin of the sintered wire mesh is ANPING.

Q4: What is the material of the sintered wire mesh?

A4: The material of the sintered wire mesh is SS.

Q5: What are the advantages of sintered wire mesh?

A5: The advantages of sintered wire mesh include high strength, low cost, good mechanical strength, and high temperature resistance.