-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Perforated Metal 200micron Sintered Wire Mesh Layer Increases Rigidity For Filter

| Place of Origin | Anping of China |

|---|---|

| Brand Name | QIANPU |

| Certification | ISO |

| Minimum Order Quantity | 100 Pieces |

| Packaging Details | Inside with plastic film, outside with carton box or wooden box, and then in a pallet. It's also available as your requirements. |

| Delivery Time | For the size we have in stock,5 working days |

| Supply Ability | 200000 piece per month |

| Features | Resistant Corrosion And High Temperature | Product Name | Perforated Sintered Wire Mesh |

|---|---|---|---|

| Perforated Metal Material | Stainless Steel 304, Stainless Steel 316 L. | Wire Mesh Material | Stainless Steel 316 L Or Stainless Steel 316. |

| Filter Rating | 2micron To 200micron | Standard Size | 500 Mm × 1000 Mm, 600 Mm × 1200 Mm, 1000 Mm × 1000 Mm, 1200 Mm × 1200 Mm, 1180 Mm × 1450 Mm, 1200 Mm × 1500 Mm, Other Sizes Can Be Customized |

| Continuous Operating Temperature Ranges | -20 °C To 600 °C | Application | Well Used In Oil Wells, Where Fine Particles Need To Be Filtered Under Extremely High Pressure Conditions. |

| Highlight | 200micron sintered wire mesh,filter perforated sintered wire mesh,200micron sintered stainless steel mesh |

||

Perforated Sintered Wire Mesh Perforated Metal Layer Increases Rigidity For Filter

Perforated sintered wire mesh Introduction

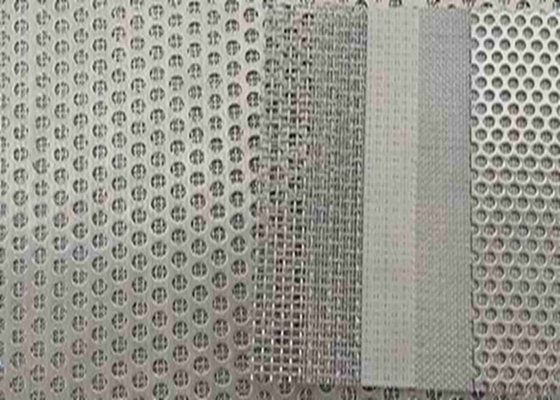

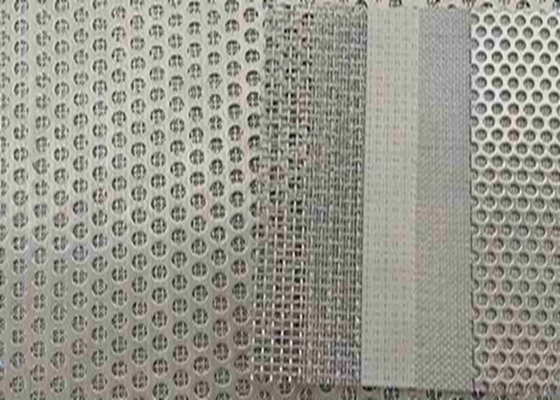

Perforated sintered wire mesh plate is made from several layers of stainless steel woven wire mesh and a perforated metal layer sintering together, usually consisting of five layers (as the left picture shown) - perforated layer, buffer layer, fine mesh, protective layer and filer layer. The above layers are sintered together to form a very study and strong multi-layers filter mesh. The perforated metal as reinforcement layer support the filter structure, which has very high compressive and mechanical strength.

Sintered mesh with perforated metal, also named perforated metal sintered wire mesh, is a kind of compound sintered mesh which fits precise filtration and the need to protect the filtration layer. It is produced by combing several layers of stainless steel woven wire meshes and then sintering them to one piece of perforated metal. The support of a perforated metal sheet makes the sintered mesh extremely resistant to pressure and offers high compressive and mechanical strength. The perforated metal laminate varies in thickness and the opening of the hole size, the woven wire mesh can be one or more layers, which all fit the need of real application. Perforated metal sintered wire mesh can also be processed into different shapes, like chip, conical, cylinders, disc and tube. Owing to its outstanding permeability and great strength, it plays an important role in diverse filtration applications such as gas and liquid separation, recycle of solid particles, etc.

Types of sinter mesh filters we supply:

standard combination of 5-layer sintered wire mesh.

sintered together by many layers of plain-woven square mesh.

sintered together by many layers of dutch-woven square mesh.

sintered by perforated plate and multi-layer stainless steel wire mesh.

Our sintered mesh panels may be formed into filter elements such as filter discs, cartridges, cones, cylinders, and tube.

Material:

Standard material AISI304, AISI316, AISI316L, Alloy Steel Hastelloy, Monel, and Inconel.

Specifications:

Filter raiting: 2 um - 200 um.

Materials: SUS 304, 316, 316L; or Alloy Steel Hastelloy, Monel, Inconel.

Standard size: 500 × 1000 mm, 600 × 1200 mm and 1000 × 1000 mm, 1200 × 1200 mm.

Perforated sintered mesh filter sheets, filter discs, and filter tube in a variety of diameters and lengths are also can be manufactured in our company.

| Specifications of Perforated Metal Sintered Wire Mesh | |||||

| Model | Filter Rating | Structure | Thickness (mm) | Weight (kg/m2) | Porosity (%) |

| (um) | |||||

| PES4-2.0T | 2 - 200 | 30+Filter layer+30+φ4 × 5P × 1.0T | 2 | 6.7 | 57 |

| PES4-2.5T | 2 - 200 | 30+Filter layer+30+φ5 × 7P × 1.5T | 2.5 | 9.8 | 50 |

| PES5-3.0T | 2 - 200 | 60+Filter layer+60+20+φ6 × 8P × 2.0T | 3 | 11.8 | 50 |

| PES5-3.5T | 2 - 200 | 20+Filter layer+20+10+φ8 × 10P × 2.0T | 3.5 | 12.6 | 54 |

| PES5-4.0T | 2 - 200 | 20+Filter layer+20+10+φ8 × 10P × 2.5T | 4 | 14.2 | 55 |

| PES5-4.3T | 5 - 200 | 20+Filter layer+20+10+φ10 × 13P × 3.0T | 4.3 | 16.9 | 50 |

| PES5-5.3T | 5 - 200 | 20+Filter layer+20+10+φ10 × 13P × 4.0T | 5.3 | 20.6 | 51 |

Features:

High mechanical strength makes the sintered mesh full of rigidity.

High corrosion and abrasion resistance prolongs its service life.

Easy for cutting, bending, welding or other processes.

Precise filtration for great permeability.

Continuous operating temperature ranges from -20 °C to 600 °C.

Easy to be back washed.

Advantages:

this type sinter mesh filter are resistant corrosion and high temperature, with wide filter rating ranges, having high mechanical strength and the ability to maintain a steady filter rating under high pressure. It is also easy to clean with a variety of filter cleaning techniques, and easy to fabricate, weld, punch, shear or made to filter cartridges and tube.

Application:

Perforated metal sintered filter is widely used in many industries where fine particles need to be filtered under extremely high pressure environment. These industries involves chemistry, pharmacy, petroleum, aviation, food, metallurgy, etc.

![]()

Photos:

![]()

![]()

Packing: warped with waterproof paper or plastic film, then in the wooden cases/ pallets. Or as your requests.

![]()

Anping Qianpu Wire Mesh Products Co., Ltd.is a manufacture and exporter of stainless steel wire mesh product.

We are located in wire mesh industrial base Anping city,Hebei province in China.

Our product range is as below,

Stainless steel woven wire mesh

Welded wire mesh

Crimped wire mesh

Hexagonal wire mesh

Knitted wire mesh

Wire mesh filter

Window screen

It have been 15 years that we manufacture and export wire mesh product,our professional responsible attitude and our strictly management technique ensure us standing in the leading position of wire mesh industry.We welcome your enquiry.

![]()

Our architectural mesh List:

Sintered Mesh

Plain Weave Sintered Mesh

Dutch Woven Sintered Wire Mesh

Perforated Metal Sintered Wire Mesh

Brass Pneumatic Mufflers / Sintered Silencer

Stainless Steel Pneumatic Mufflers / Sintered Silencer

Sintered Filter Elements

Sintered Mesh Filter Cartridges

Sintered Metal Filter Disc

Sintered Wire Mesh Laminates

Sintered Tube Filter

Stainless Steel Sintered Fiber Felt

Iron-Chromium-Aluminum Fiber Felt

Sintered Stainless Steel Powder Filter Element

Titanium Powder Sintered Filter

Sintered Copper Powder Filter Elements

Five-Layer Sintered Mesh

Sintered Mesh Laminate

Sintered Mesh With Perforated Metal

Sintered Metal Filter Cartridge

Pleated Sintered Mesh Filter

Sintered Mesh Cone Filter

Sintered Metal Fiber Felt