-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

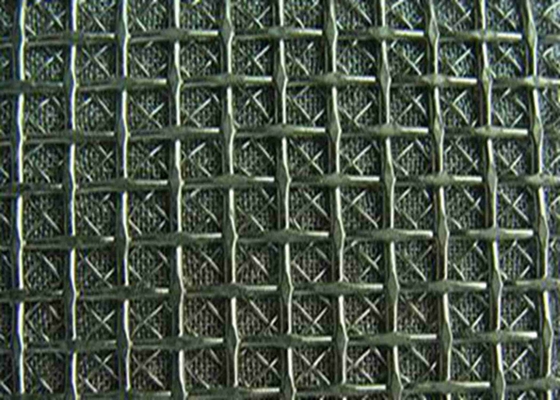

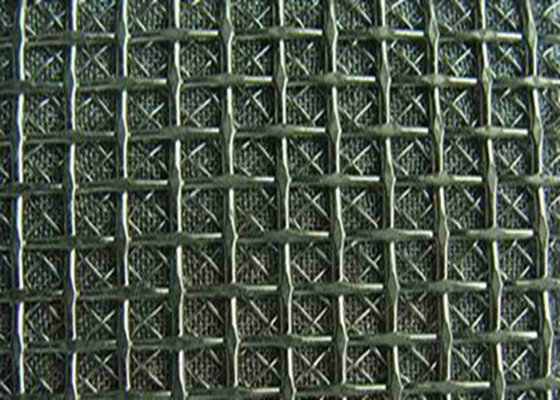

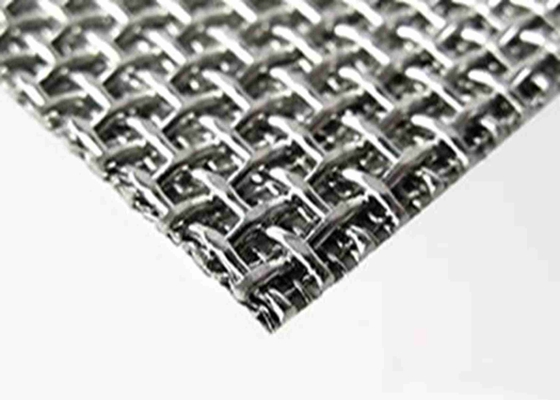

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

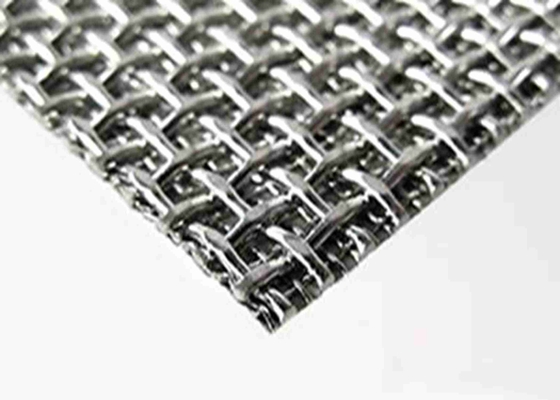

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Plain Weave 200um Sintered Wire Mesh Square Woven For Polymer Production

| Place of Origin | Anping of China |

|---|---|

| Brand Name | QIANPU |

| Certification | ISO |

| Minimum Order Quantity | 100 Pieces |

| Packaging Details | Inside with plastic film, outside with carton box or wooden box, and then in a pallet. It's also available as your requirements. |

| Delivery Time | For the size we have in stock,5 working days |

| Supply Ability | 200000 piece per month |

| Features | High Flow Characteristics | Product Name | Plain Weave Sintered Square Woven Wire Mesh |

|---|---|---|---|

| Material | Standard Material AISI304, AISI316, AISI316L, Alloy Steel Hastelloy, Monel, And Inconel. | Number Of Layers | 5-layers |

| Filter Rating | 1µm To 200µm | Over Thickness | 0.5mm To 2.0 Mm |

| Standard Size | 300 × 1000 Mm, 500 × 1000 Mm, 600 × 1200 Mm, 1000 × 1000 Mm, 1200 × 1200 Mm, 1000 × 1500 Mm, 1200 × 1500 Mm. | Fabrication | Easily Formed, Sheared, Welded And Punched. |

| Porosity | 44%, 50%, 54%, 60% ,etc | Application | T Is Useful For Polymer Production, As Well As A Variety Of Fluid And Air Filtration Applications. |

| Highlight | 200um sintered wire mesh,polymer production sintered wire mesh,polymer production sintered wire cloth |

||

Plain Weave Sintered Square Woven Wire Mesh Used For Polymer Production

Plain Weave Sintered Square Woven Wire Mesh Introduction

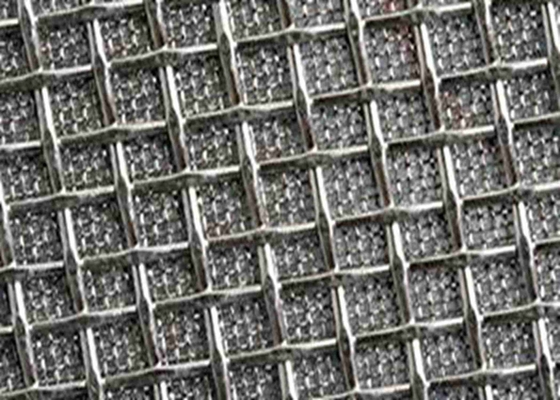

Plain weave sintered square woven wire mesh is made by sintering multiple layers of plain weave square woven mesh together, and its cross section structure as below picture. Because of the large open area percentages of the square woven wire mesh layers, this type of sintered wire mesh has good permeability characteristics and low resistance to flow. It can be designed with any number and combination of square plain weave wire mesh layers to achieve particular flow and filtration characteristics. It is useful for polymer production, as well as a variety of fluid and air filtration applications.

Another possibility with this type of stainless steel sintered wire mesh is the ability to sinter a large number of layers of square woven wire mesh together to form parts that are very thick and useful as flame and detonation arrestors. These laminates can be inches thick and still be made with high flow characteristics.

Types of sinter mesh filters we supply:

standard combination of 5-layer sintered wire mesh.

sintered together by many layers of plain-woven square mesh.

sintered together by many layers of dutch-woven square mesh.

sintered by perforated plate and multi-layer stainless steel wire mesh.

Our sintered mesh panels may be formed into filter elements such as filter discs, cartridges, cones, cylinders, and tube.

Super Sintered Wire Mesh Characterastics:

1.Wide range of filter rating;

2.Steady filter rating;

3.HIgh mechanical strength;

4.Easy to wash;

5.Heat resistance;

6.Corrosion resistance;

7.Tractability

Material:

Standard material AISI304, AISI316, AISI316L, Alloy Steel Hastelloy, Monel, and Inconel.

Specifications:

Filter Rating: 1 um - 200 um.

Materials: SUS304 (AISI304), SUS316 (AISI316), SUS316L (AISI316L).

Size: 300 × 1000 mm, 500 × 1000 mm, 600 × 1200 mm, 1000 × 1000 mm, 1200 × 1200 mm, 1000 × 1500 mm, 1200 × 1500 mm.

This type sinter mesh be cut and fabricated into various discs, tubes, filter cartridges, and flat panels.

| Table of Plain Weave Sintered Mesh Technical Parameters | |||||

| Model | Structure | Filter rating (u) | Thickness (mm) | Weight | Porosity (%) |

| (kg/ m2) | |||||

| PS2-0.5T | Filter layer + 60 | 2-100 | 0.5 | 1.6 | 60 |

| PS3-0.7T | 60 + Filter layer + 60 | 2-100 | 0.7 | 2.4 | 56 |

| PS3-1.0T | 50 + Filter layer + 20 | 20-200 | 1 | 3.3 | 58 |

| PS3-2.0T | Filter layer + 20 + 8.5 | 20-250 | 2 | 6.5 | 58 |

| PS4-1.0T | 60 + Filter layer + 40 + 20 | 2-200 | 1 | 4.4 | 44 |

| PS4-1.7T | 40 + Filter layer + 20 + 16 | 2-200 | 1.7 | 6.2 | 54 |

| PS5-1.9T | 30 + Filter layer + 60 + 20 + 16 | 2-200 | 1.9 | 5.3 | 52 |

| PS5-2.5T | 80 + Filter layer + 30 + 10 + 8.5 | 2-200 | 2.5 | 8.8 | 55 |

| PS7-2.0T | 50 + Filter layer + 40 + 20 + 40 + Filter layer + 50 | 2-150 | 2 | 7.4 | 58 |

Advantages:

High strength and durability since high temperature sintering.

Anti-corrosion, and heat resistance up to 480 °C.

Steady filter rating from the 1micron to 100 micron.

Filter mesh not easy to deform because of two protective layers.

Can used for uniform filtration in high pressure or high viscosity environment.

Suits for cutting, bending, punching, stretching, and welding.

Application:

Sinter wire mesh filters are usually used for purification and filtration of liquid and gas, separation and recovery of solid particle, transpiration cooling under extremity high temperature, control air flow distribution, enhancement of heat and mass transfer, noise reduction, current limitation, and wildly used in aerospace, petrochemical industry, pharmaceutical industry, environmental protection industry.

Square plain woven sintered mesh cross section structure

![]()

![]()

![]()

Packing: warped with waterproof paper or plastic film, then in the wooden cases/ pallets. Or as your requests.

![]()

Anping Qianpu Wire Mesh Products Co., Ltd.is a manufacture and exporter of stainless steel wire mesh product.

We are located in wire mesh industrial base Anping city,Hebei province in China.

Our product range is as below,

Stainless steel woven wire mesh

Welded wire mesh

Crimped wire mesh

Hexagonal wire mesh

Knitted wire mesh

Wire mesh filter

Window screen

It have been 15 years that we manufacture and export wire mesh product,our professional responsible attitude and our strictly management technique ensure us standing in the leading position of wire mesh industry.We welcome your enquiry.

![]()

Our architectural mesh List:

Sintered Mesh

Plain Weave Sintered Mesh

Dutch Woven Sintered Wire Mesh

Perforated Metal Sintered Wire Mesh

Brass Pneumatic Mufflers / Sintered Silencer

Stainless Steel Pneumatic Mufflers / Sintered Silencer

Sintered Filter Elements

Sintered Mesh Filter Cartridges

Sintered Metal Filter Disc

Sintered Wire Mesh Laminates

Sintered Tube Filter

Stainless Steel Sintered Fiber Felt

Iron-Chromium-Aluminum Fiber Felt

Sintered Stainless Steel Powder Filter Element

Titanium Powder Sintered Filter

Sintered Copper Powder Filter Elements

Five-Layer Sintered Mesh

Sintered Mesh Laminate

Sintered Mesh With Perforated Metal

Sintered Metal Filter Cartridge

Pleated Sintered Mesh Filter

Sintered Mesh Cone Filter

Sintered Metal Fiber Felt