-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Selvage Edge Stainless Steel Wire Mesh Prevent Individual Wires From Loosening Or Unraveling

| Place of Origin | Anping of China |

|---|---|

| Brand Name | QIANPU |

| Certification | ISO |

| Minimum Order Quantity | 5 Rolls |

| Price | Negotiable |

| Packaging Details | Inside with a paper tube, outside with plastic film or waterproof paper, then in wooden case or pallets. |

| Delivery Time | Immediately |

| Payment Terms | T/T, Western Union, L/C |

| Product Name | SS Woven Wire Mesh | Material | Stainless Steel |

|---|---|---|---|

| Surface | Bright Silver | Aperture Shape | Square |

| Properity | Superior Corrosion Resistance | Application | Filtration |

| Highlight | Unraveling Stainless Steel Wire Mesh,Individual Wires Stainless Steel Wire Mesh,Selvage Edge Stainless Steel Wire Mesh |

||

Selvage Edge Stainless Steel Wire Mesh Prevent The Individual Wires From Loosening Or Unraveling

Indtroduction:

In the context of stainless steel wire mesh, the "selvage edge" refers to the finished edge of the mesh fabric. Selvage edges are designed to provide a clean and secure edge finish to the wire mesh, preventing unraveling or fraying of the mesh fabric. Here are some key points related to selvage edge in stainless steel wire mesh:

Purpose: The selvage edge serves to reinforce the edges of the wire mesh, enhancing the overall durability and longevity of the mesh structure.

Prevention of Unraveling: By securing the edges of the wire mesh, selvage edges help prevent the individual wires from loosening or unraveling, which could compromise the integrity of the mesh.

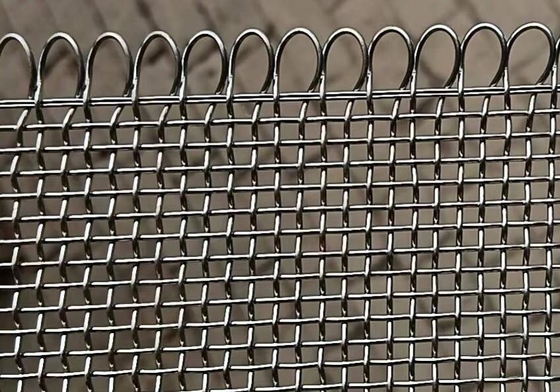

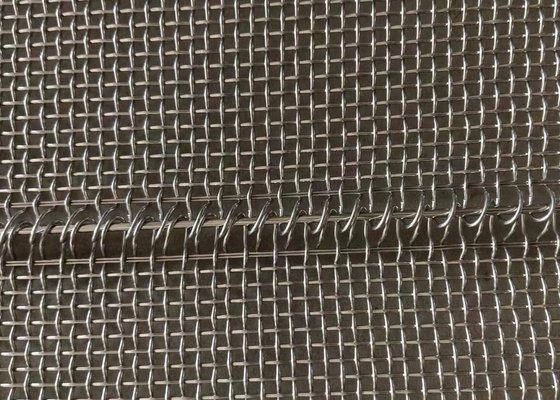

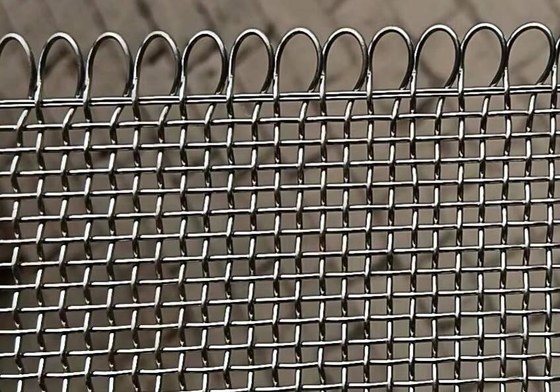

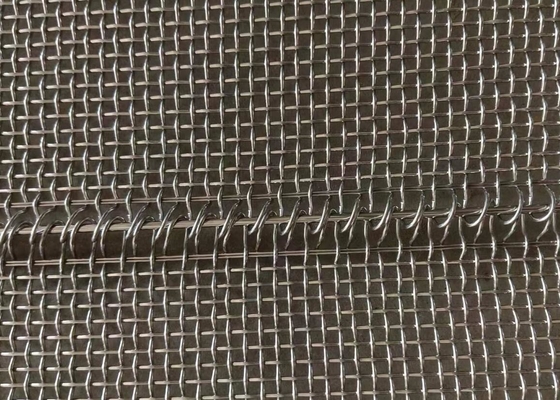

Types of Selvage Edges: There are different types of selvage edges used in wire mesh, including welded selvage, looped selvage, and knuckled selvage. Each type offers distinct features and benefits in terms of strength and appearance.

Welded Selvage: In welded selvage, the wires at the edge of the mesh are welded together to create a strong and secure edge. This type of selvage provides excellent strength and stability but may have a more pronounced edge compared to other types.

Looped Selvage: Looping involves bending the wires at the edge of the mesh to form a looped configuration. This type of selvage offers a smoother edge finish and is often used in applications where a more aesthetically pleasing appearance is desired.

Knuckled Selvage: Knuckling involves interlocking the wires at the edge of the mesh to create a smooth and rounded edge. Knuckled selvage provides a safe and snag-free edge, making it suitable for applications where safety is a concern.

Applications: Selvage-edged stainless steel wire mesh is commonly used in various industries, including filtration, separation, reinforcement, security, and architectural applications where a durable and well-finished edge is required.

When selecting stainless steel wire mesh with selvage edge, it's important to consider the specific requirements of your application, including the type of selvage edge, mesh size, wire diameter, material grade, and overall durability needed. Consulting with a wire mesh supplier or manufacturer can help you choose the right type of selvage-edged stainless steel wire mesh that best suits your project requirements.

Specifications:

| Mesh/Inch | Wire Diameter | Aperture | Open Area (%) |

Weight (kg /Square meter) |

||

| Inch | MM | Inch | MM | |||

| 4X4 | .047 | 1.19 | .203 | 5.16 | 81.2 | 2.7 |

| 5X5 | .041 | 1.04 | .159 | 4.04 | 79.5 | 2.6 |

| 6x6 | .035 | 0.89 | .145 | 3.68 | 2.1 | |

| 8 x 8 | .32 | 0.81 | .113 | 2.88 | 2.6 | |

| 10X10 | .025 | .64 | .075 | 1.91 | 74.9 | 2.0 |

| 12X12 | .020 | .508 | .063 | 1.60 | 75.9 | 1.5 |

| 14X14 | .020 | .508 | .051 | 1.30 | 71.9 | 1.8 |

| 16X16 | .018 | .457 | .0445 | 1.13 | 71.2 | 1.6 |

| 18X18 | .017 | .432 | .0386 | .98 | 69.4 | 1.6 |

| 20X20 | .020 | .240 | .0300 | .76 | 76.0 | .56 |

| 20X20 | .016 | .330 | .0340 | .86 | 72.2 | 1.1 |

| 30X30 | .0120 | .305 | .0213 | .54 | 63.9 | 1.4 |

| 30X30 | .0094 | .240 | .0243 | .62 | 72.1 | .84 |

Other specifications according to your requirements.

Materials:

304, 304L, 316, 316L

Features:

Corrosion Resistance: One of the most prominent features of stainless steel is its excellent resistance to corrosion. This is due to the presence of chromium in the alloy, which forms a protective oxide layer on the surface of the material, preventing rust and corrosion.

Strength and Durability: Stainless steel is a strong and durable material that can withstand a wide range of environmental conditions and mechanical stresses. It is commonly used in applications where strength and longevity are essential.

Hygiene and Cleanliness: Stainless steel is non-porous, making it easy to clean and resistant to bacteria growth. This property makes it a popular choice for applications where hygiene is crucial, such as in the food and medical industries.

Aesthetic Appeal: Stainless steel has a modern and attractive appearance that fits well in various design styles. It is often used in architectural, interior design, and decorative applications.

Temperature Resistance: Stainless steel can withstand high and low temperatures without losing its mechanical properties, making it suitable for applications that involve extreme temperature conditions.

Recyclability: Stainless steel is a highly recyclable material, making it an environmentally friendly choice. It can be recycled and reused without losing its quality.

Versatility: Stainless steel is available in various grades and finishes to suit different applications. Common grades include 304 (most common), 316, 430, and more, each with specific properties for different uses.

Magnetic Properties: Some types of stainless steel are magnetic, while others are not. This property is important in applications where magnetic properties are a consideration.

Resistance to Staining: Stainless steel is resistant to staining and can maintain its appearance over time with proper care and maintenance.

Applications:

Selvage edge wire mesh, with its reinforced edges and secure finish, finds applications in various industries where durability, stability, and safety are essential. Here are some common applications of selvage edge wire mesh:

Security Fencing: Selvage edge wire mesh is often used in security fencing applications where a strong and tamper-resistant barrier is required. The reinforced edges provide added strength and prevent unauthorized entry.

Perimeter Fencing: In commercial, industrial, and residential settings, selvage edge wire mesh is used for perimeter fencing to secure property boundaries. The secure edges help maintain the integrity of the fence over time.

Animal Enclosures: Selvage edge wire mesh is utilized in animal enclosures, such as zoos, farms, and pet kennels, to create secure and durable enclosures for animals. The reinforced edges prevent animals from damaging or escaping through the mesh.

Safety Barriers: In industrial settings, selvage edge wire mesh is employed as safety barriers to protect workers from hazardous machinery or areas. The sturdy edges enhance the safety and durability of these barriers.

Landscaping and Garden Fencing: Selvage edge wire mesh is used in landscaping and garden fencing applications to create boundaries, protect plants, and enhance the aesthetics of outdoor spaces. The reinforced edges ensure long-lasting performance in outdoor environments.

Partitioning Systems: Wire mesh partitioning systems in warehouses, storage facilities, and commercial spaces often utilize selvage edge wire mesh for secure and stable partitions. The reinforced edges help maintain the structure and integrity of the partitions.

Construction and Infrastructure: In construction projects, selvage edge wire mesh is used for reinforcing concrete structures, such as walls and foundations. The secure edges ensure proper alignment and stability during concrete pouring.

Filtration and Screening: Selvage edge wire mesh is employed in filtration and screening applications in industries such as mining, agriculture, and wastewater treatment. The reinforced edges help maintain the structural integrity of the mesh during filtration processes.

Decorative Applications: In architectural and interior design, selvage edge wire mesh is used for decorative purposes, such as wall cladding, ceiling panels, and artistic installations. The secure edges provide a clean and finished look.

Industrial Storage: Selvage edge wire mesh is used in industrial shelving and storage systems to create sturdy shelves and partitions for organizing and storing goods. The reinforced edges ensure the stability of the storage units.

These applications demonstrate the versatility and reliability of selvage edge wire mesh in various sectors where robust and long-lasting wire mesh solutions are required.

![]()

Packing:

![]()