-

SS Welded Wire Mesh

-

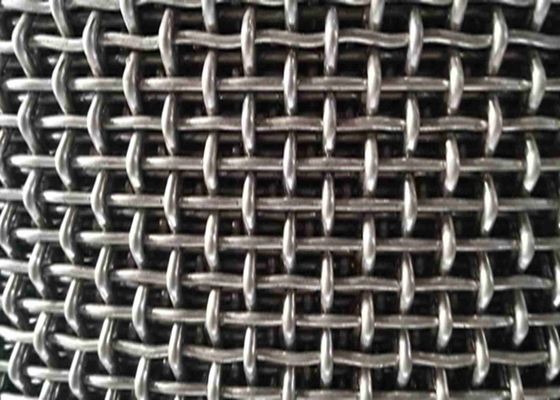

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

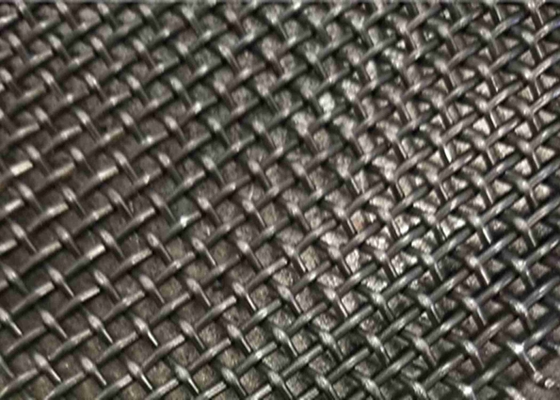

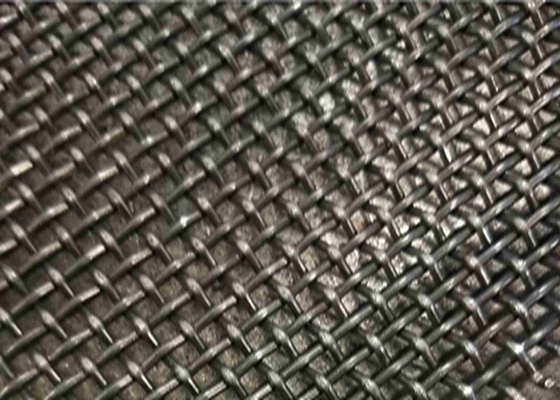

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Versatile Steel Woven Mesh Commonly Used Material In Various Industries

| Place of Origin | Anping of China |

|---|---|

| Brand Name | QIANPU |

| Certification | ISO |

| Minimum Order Quantity | 5 Rolls |

| Price | Negotiable |

| Packaging Details | Inside with a paper tube, outside with plastic film or waterproof paper, then in wooden case or pallets. |

| Delivery Time | Immediately |

| Payment Terms | T/T, Western Union, L/C |

| Product Name | SS Woven Wire Mesh | Material | Stainless Steel 304 |

|---|---|---|---|

| Surface | Bright Silver | Aperture Shape | Square |

| Mesh Counts | 40 | Wire Diameter | 0.25mm |

| Roll Width | 1m, 1.22m, 1.6m Stock | Standard Length | 30m |

| Properity | Superior Corrosion Resistance | Application | Filtration |

| Highlight | Versatile Woven Wire Mesh,Stainless Steel Woven Wire Mesh,Commonly Used Woven Wire Mesh |

||

Stainless Steel Woven Wire Mesh Is A Versatile And Commonly Used Material In Various Industries

Indtroduction:

Stainless steel woven wire mesh is a versatile and commonly used material in various industries due to its durability, corrosion resistance, and strength. Here are some key features and considerations regarding stainless steel woven wire mesh:

Corrosion Resistance: Stainless steel woven wire mesh is highly resistant to corrosion, making it suitable for use in aggressive environments, including marine, chemical, and industrial settings.

Strength and Durability: Stainless steel wire mesh is known for its strength and durability, allowing it to withstand mechanical stress and harsh conditions.

Versatility: Stainless steel woven wire mesh is available in various weave patterns (such as plain weave, twill weave, and Dutch weave) and mesh sizes to suit different applications, including filtration, sieving, shielding, and decorative purposes.

Easy to Fabricate: Stainless steel wire mesh is easy to cut, bend, and shape, making it convenient for custom fabrication to fit specific project requirements.

Hygienic Properties: Stainless steel is easy to clean and maintain, making it suitable for applications where hygiene is essential, such as in food processing and pharmaceutical industries.

Temperature Resistance: Stainless steel wire mesh can withstand high temperatures, making it suitable for applications where heat resistance is required.

Aesthetic Appeal: Stainless steel wire mesh has a modern and clean appearance, making it a popular choice for architectural and decorative applications.

Non-Magnetic Options: Stainless steel wire mesh is available in both magnetic and non-magnetic grades, providing flexibility for applications where magnetic properties are a consideration.

Various Grades Available: Different grades of stainless steel (such as 304, 316, and 316L) offer varying levels of corrosion resistance and mechanical properties, allowing for selection based on specific application needs.

Wide Range of Applications: Stainless steel woven wire mesh is used in industries such as aerospace, automotive, construction, mining, agriculture, petrochemical, and more for purposes ranging from filtration to security.

When selecting stainless steel woven wire mesh, it's important to consider factors such as mesh size, wire diameter, weave pattern, material grade, and specific application requirements to ensure optimal performance and longevity. Consulting with a wire mesh supplier or manufacturer can help you choose the right type of stainless steel woven wire mesh for your project.

Plain Weave Mesh Specifications:

| Mesh | Wire D | Aperture L | Open Area | Square Meter Weight | |||

| openings/inch | mm | inch | mm | inch | % | kgs | lbs |

| 3 | 1.60 | 0.0629 | 6.866 | 0.2703 | 65.77 | 3.84 | 8.44 |

| 3 | 1.40 | 0.0551 | 7.066 | 0.2782 | 69.66 | 2.94 | 6.46 |

| 3 | 1.20 | 0.0472 | 7.266 | 0.2860 | 73.66 | 2.16 | 4.75 |

| 3 | 1.00 | 0.0393 | 7.466 | 0.2939 | 77.77 | 1.50 | 3.30 |

| 3 | 0.90 | 0.0354 | 7.566 | 0.2979 | 79.87 | 1.21 | 2.67 |

| 3 | 0.80 | 0.0314 | 7.666 | 0.3018 | 81.99 | 0.96 | 2.11 |

| 3 | 0.70 | 0.0275 | 7.766 | 0.3057 | 84.14 | 0.73 | 1.60 |

| 4 | 1.20 | 0.0472 | 5.15 | 0.2027 | 65.77 | 2.88 | 6.33 |

| 4 | 1.00 | 0.0393 | 5.35 | 0.2106 | 70.98 | 2.00 | 4.40 |

| 4 | 0.90 | 0.0354 | 5.45 | 0.2145 | 73.66 | 1.62 | 3.56 |

| 4 | 0.80 | 0.0314 | 5.55 | 0.2185 | 76.39 | 1.28 | 2.81 |

| 4 | 0.70 | 0.0275 | 5.65 | 0.2224 | 79.16 | 0.98 | 2.15 |

| 4 | 0.60 | 0.0236 | 5.75 | 0.2263 | 81.99 | 0.72 | 1.58 |

| 5 | 1.00 | 0.0393 | 4.08 | 0.1606 | 64.50 | 2.50 | 5.50 |

| 5 | 0.90 | 0.0354 | 4.18 | 0.1645 | 67.70 | 2.02 | 4.45 |

| 5 | 0.80 | 0.0314 | 4.28 | 0.1685 | 70.98 | 1.60 | 3.52 |

| 5 | 0.70 | 0.0275 | 4.38 | 0.1724 | 74.33 | 1.22 | 2.68 |

| 5 | 0.60 | 0.0236 | 4.48 | 0.1763 | 77.77 | 0.90 | 1.98 |

| 5 | 0.50 | 0.0196 | 4.58 | 0.1803 | 81.28 | 0.62 | 1.37 |

| 6 | 0.90 | 0.0354 | 3.333 | 0.1312 | 62.00 | 2.43 | 5.34 |

| 6 | 0.80 | 0.0314 | 3.433 | 0.1351 | 65.77 | 1.92 | 4.22 |

| 6 | 0.70 | 0.0275 | 3.533 | 0.1391 | 69.66 | 1.47 | 3.23 |

| 6 | 0.60 | 0.0236 | 3.633 | 0.1430 | 73.66 | 1.08 | 2.37 |

| 6 | 0.50 | 0.0196 | 3.733 | 0.1469 | 77.77 | 0.75 | 1.65 |

| 8 | 0.90 | 0.0354 | 2.275 | 0.0895 | 51.34 | 3.24 | 7.12 |

| 8 | 0.80 | 0.0314 | 2.375 | 0.0935 | 55.95 | 2.56 | 5.63 |

| 8 | 0.70 | 0.0275 | 2475 | 0.0974 | 60.76 | 1.96 | 4.31 |

| 8 | 0.60 | 0.0236 | 2575 | 0.1013 | 65.77 | 1.44 | 3.16 |

| 8 | 0.50 | 0.0196 | 2675 | 0.1053 | 70.98 | 1.00 | 2.20 |

| 10 | 0.90 | 0.0354 | 1.640 | 0.0645 | 41.68 | 4.05 | 8.91 |

| 10 | 0.80 | 0.0314 | 1.740 | 0.0685 | 46.92 | 3.2 | 7.04 |

| 10 | 0.70 | 0.0275 | 1.840 | 0.0724 | 52.47 | 2.45 | 5.39 |

| 10 | 0.60 | 0.0236 | 1.940 | 0.0763 | 58.33 | 1.8 | 3.96 |

| 10 | 0.50 | 0.0196 | 2.040 | 0.0803 | 64.50 | 1.25 | 2.75 |

| 10 | 0.40 | 0.0157 | 2.140 | 0.0842 | 70.98 | 0.80 | 1.76 |

| 12 | 0.80 | 0.0314 | 1.316 | 0.0518 | 38.69 | 3.84 | 8.44 |

| 12 | 0.70 | 0.0275 | 1.416 | 0.0557 | 44.79 | 2.94 | 6.46 |

| 12 | 0.60 | 0.0236 | 1.516 | 0.0597 | 51.34 | 2.16 | 4.75 |

| 12 | 0.50 | 0.0196 | 1.616 | 0.0636 | 58.33 | 1.50 | 3.30 |

| 12 | 0.40 | 0.0157 | 1.716 | 0.0675 | 65.77 | 0.96 | 2.11 |

| 12 | 0.30 | 0.0118 | 1.816 | 0.0715 | 73.66 | 0.54 | 1.18 |

| 14 | 0.70 | 0.0275 | 1.114 | 0.0438 | 37.72 | 3.43 | 7.54 |

| 14 | 0.60 | 0.0236 | 1.214 | 0.0478 | 44.79 | 2.52 | 5.54 |

| 14 | 0.50 | 0.0196 | 1.314 | 0.0517 | 52.47 | 1.75 | 3.85 |

| 14 | 0.40 | 0.0157 | 1.414 | 0.0556 | 60.76 | 1.12 | 2.46 |

| 14 | 0.35 | 0.0137 | 1.464 | 0.0576 | 65.13 | 0.85 | 1.87 |

| 14 | 0.30 | 0.0118 | 1.514 | 0.0596 | 69.66 | 0.63 | 1.38 |

| 14 | 0.27 | 0.0106 | 1.544 | 0.0607 | 72.45 | 0.51 | 1.12 |

| 14 | 0.25 | 0.0098 | 1.564 | 0.0615 | 74.33 | 0.43 | 0.94 |

| 14 | 0.23 | 0.0090 | 1.584 | 0.0623 | 76.25 | 0.37 | 0.81 |

| 14 | 0.21 | 0.0082 | 1.604 | 0.0631 | 78.19 | 0.30 | 0.67 |

| 14 | 0.19 | 0.0074 | 1.624 | 0.0639 | 80.15 | 0.25 | 0.55 |

| 16 | 0.60 | 0.0236 | 0.987 | 0.0388 | 38.69 | 2.88 | 6.33 |

| 16 | 0.50 | 0.0196 | 1.087 | 0.0428 | 46.92 | 2.00 | 4.40 |

| 16 | 0.40 | 0.0157 | 1.187 | 0.0467 | 55.95 | 1.28 | 2.81 |

| 16 | 0.35 | 0.0137 | 1.237 | 0.0487 | 60.76 | 0.98 | 2.15 |

| 16 | 0.30 | 0.0118 | 1.287 | 0.0506 | 65.77 | 0.72 | 1.58 |

| 16 | 0.27 | 0.0106 | 1.317 | 0.0518 | 68.87 | 0.58 | 1.27 |

| 16 | 0.25 | 0.0098 | 1.337 | 0.0526 | 70.98 | 0.50 | 1.10 |

| 16 | 0.23 | 0.0090 | 1.357 | 0.0534 | 73.12 | 0.42 | 0.92 |

| 16 | 0.21 | 0.0082 | 1.377 | 0.0542 | 75.29 | 0.35 | 0.77 |

| 16 | 0.19 | 0.0074 | 1.397 | 0.0550 | 77.49 | 0.28 | 0.61 |

| 18 | 0.50 | 0.0196 | 0.911 | 0.0358 | 41.68 | 2.25 | 4.95 |

| 18 | 0.40 | 0.0157 | 1.011 | 0.0398 | 51.34 | 1.44 | 3.16 |

| 18 | 0.35 | 0.0137 | 1.061 | 0.0417 | 56.54 | 1.10 | 2.42 |

| 18 | 0.30 | 0.0118 | 1.111 | 0.0437 | 62.00 | 0.81 | 1.78 |

| 18 | 0.27 | 0.0106 | 1.141 | 0.0449 | 65.39 | 0.65 | 1.44 |

| 18 | 0.25 | 0.0098 | 1.161 | 0.0457 | 67.70 | 0.56 | 1.23 |

| 18 | 0.23 | 0.0090 | 1.181 | 0.0465 | 70.05 | 0.47 | 1.04 |

| 18 | 0.21 | 0.0082 | 1.201 | 0.0472 | 72.45 | 0.39 | 0.87 |

| 18 | 0.19 | 0.0074 | 1.221 | 0.0480 | 74.88 | 0.32 | 0.71 |

| 18 | 0.17 | 0.0066 | 1.241 | 0.0488 | 77.35 | 0.26 | 0.57 |

| 18 | 0.15 | 0.0059 | 1.261 | 0.0496 | 79.87 | 0.20 | 0.44 |

| 20 | 0.50 | 0.0196 | 0.770 | 0.0303 | 36.75 | 2.50 | 5.50 |

| 20 | 0.45 | 0.0177 | 0.820 | 0.0322 | 41.68 | 2.02 | 4.44 |

| 20 | 0.40 | 0.0157 | 0.870 | 0.0342 | 46.92 | 1.60 | 3.52 |

| 20 | 0.35 | 0.0137 | 0.920 | 0.0362 | 52.47 | 1.22 | 2.69 |

| 20 | 0.30 | 0.0118 | 0.970 | 0.0381 | 58.33 | 0.90 | 1.98 |

| 20 | 0.27 | 0.0106 | 1.000 | 0.0393 | 62.00 | 0.72 | 1.60 |

| 20 | 0.25 | 0.0098 | 1.020 | 0.0401 | 64.50 | 0.62 | 1.36 |

| 20 | 0.23 | 0.0090 | 1.040 | 0.0409 | 67.05 | 0.52 | 1.16 |

| 20 | 0.21 | 0.0082 | 1.060 | 0.0417 | 69.66 | 0.44 | 0.97 |

| 20 | 0.19 | 0.0074 | 1.080 | 0.0425 | 72.31 | 0.36 | 0.79 |

| 20 | 0.17 | 0.0066 | 1.100 | 0.0433 | 75.02 | 0.28 | 0.63 |

| 20 | 0.15 | 0.0059 | 1.120 | 0.0440 | 77.77 | 0.22 | 0.49 |

| 22 | 0.40 | 0.0157 | 0.754 | 0.0297 | 42.71 | 1.76 | 3.87 |

| 22 | 0.35 | 0.0137 | 0.804 | 0.0316 | 48.56 | 1.34 | 2.96 |

| 22 | 0.30 | 0.0118 | 0.854 | 0.0336 | 54.78 | 0.99 | 2.17 |

| 22 | 0.27 | 0.0106 | 0.884 | 0.0348 | 58.69 | 0.80 | 1.76 |

| 22 | 0.25 | 0.0098 | 0.904 | 0.0356 | 61.38 | 0.68 | 1.49 |

| 22 | 0.23 | 0.0090 | 0.924 | 0.0363 | 64.12 | 0.58 | 1.27 |

| 22 | 0.21 | 0.0082 | 0.944 | 0.0371 | 66.93 | 0.48 | 1.05 |

| 22 | 0.19 | 0.0074 | 0.964 | 0.0379 | 69.79 | 0.39 | 0.87 |

| 22 | 0.17 | 0.0066 | 0.984 | 0.0387 | 72.71 | 0.31 | 0.69 |

| 22 | 0.15 | 0.0059 | 1.004 | 0.0395 | 75.70 | 0.24 | 0.54 |

| 24 | 0.35 | 0.0137 | 0.708 | 0.0278 | 44.79 | 1.47 | 3.23 |

| 24 | 0.30 | 0.0118 | 0.758 | 0.0298 | 51.34 | 1.08 | 2.37 |

| 24 | 0.27 | 0.0106 | 0.788 | 0.0310 | 55.48 | 0.87 | 1.92 |

| 24 | 0.25 | 0.0098 | 0.808 | 0.0318 | 58.33 | 0.75 | 1.65 |

| 24 | 0.23 | 0.0090 | 0.828 | 0.0326 | 61.25 | 0.63 | 1.38 |

| 24 | 0.21 | 0.0082 | 0.848 | 0.0333 | 64.25 | 0.52 | 1.14 |

| 24 | 0.19 | 0.0074 | 0.868 | 0.0341 | 67.31 | 0.43 | 0.95 |

| 24 | 0.17 | 0.0066 | 0.888 | 0.0349 | 70.45 | 0.34 | 0.76 |

| 24 | 0.15 | 0.0059 | 0.908 | 0.0357 | 73.66 | 0.27 | 0.59 |

| 24 | 0.13 | 0.0051 | 0.928 | 0.0365 | 76.94 | 0.20 | 0.44 |

| 24 | 0.12 | 0.0047 | 0.938 | 0.0369 | 78.60 | 0.17 | 0.38 |

| 30 | 0.35 | 0.0137 | 0.496 | 0.0195 | 34.41 | 1.83 | 4.02 |

| 30 | 0.30 | 0.0118 | 0.546 | 0.0215 | 41.68 | 1.35 | 2.97 |

| 30 | 0.27 | 0.0106 | 0.576 | 0.0227 | 46.39 | 1.09 | 2.40 |

| 30 | 0.25 | 0.0098 | 0.596 | 0.0234 | 49.66 | 0.93 | 2.04 |

| 30 | 0.23 | 0.0090 | 0.616 | 0.0242 | 53.04 | 0.79 | 1.73 |

| 30 | 0.21 | 0.0082 | 0.636 | 0.0250 | 56.54 | 0.66 | 1.45 |

| 30 | 0.19 | 0.0074 | 0.656 | 0.0258 | 60.15 | 0.54 | 1.18 |

| 30 | 0.17 | 0.0066 | 0.676 | 0.0266 | 63.87 | 0.43 | 0.95 |

| 30 | 0.15 | 0.0059 | 0.696 | 0.0274 | 67.70 | 0.33 | 0.74 |

| 30 | 0.13 | 0.0051 | 0.716 | 0.0282 | 71.64 | 0.25 | 0.55 |

| 30 | 0.12 | 0.0047 | 0.726 | 0.0286 | 73.66 | 0.21 | 0.47 |

| 32 | 0.28 | 0.0110 | 0.513 | 0.0202 | 41.89 | 1.25 | 2.75 |

| 32 | 0.25 | 0.0098 | 0.543 | 0.0214 | 46.92 | 1.00 | 2.20 |

| 32 | 0.23 | 0.0090 | 0.563 | 0.0221 | 50.44 | 0.84 | 1.86 |

| 32 | 0.21 | 0.0082 | 0.583 | 0.0229 | 54.08 | 0.70 | 1.55 |

| 32 | 0.19 | 0.0074 | 0.603 | 0.0237 | 57.85 | 0.57 | 1.27 |

| 32 | 0.17 | 0.0066 | 0.623 | 0.0245 | 61.75 | 0.46 | 1.01 |

| 32 | 0.15 | 0.0059 | 0.643 | 0.0253 | 65.77 | 0.36 | 0.79 |

| 35 | 0.30 | 0.0118 | 0.425 | 0.0167 | 34.41 | 1.57 | 3.46 |

| 35 | 0.28 | 0.0110 | 0.445 | 0.0175 | 37.72 | 1.37 | 3.01 |

| 35 | 0.25 | 0.0098 | 0.475 | 0.0187 | 42.96 | 1.09 | 2.40 |

| 35 | 0.23 | 0.0091 | 0.496 | 0.0195 | 46.66 | 0.93 | 2.04 |

| 35 | 0.21 | 0.0082 | 0.515 | 0.0203 | 50.49 | 0.77 | 1.69 |

| 35 | 0.19 | 0.0074 | 0.535 | 0.0210 | 54.49 | 0.63 | 1.38 |

| 35 | 0.17 | 0.0066 | 0.555 | 0.0218 | 58.63 | 0.50 | 1.11 |

| 35 | 0.15 | 0.0059 | 0.575 | 0.0226 | 62.93 | 0.39 | 0.86 |

| 40 | 0.30 | 0.0118 | 0.335 | 0.0131 | 27.83 | 1.8 | 3.96 |

| 40 | 0.27 | 0.0106 | 0.365 | 0.0143 | 33.03 | 1.45 | 3.20 |

| 40 | 0.25 | 0.0098 | 0.385 | 0.0151 | 36.75 | 1.25 | 2.75 |

| 40 | 0.23 | 0.0090 | 0.405 | 0.0159 | 40.67 | 1.05 | 2.31 |

| 40 | 0.21 | 0.0082 | 0.425 | 0.0167 | 44.79 | 0.88 | 1.94 |

| 40 | 0.19 | 0.0074 | 0.445 | 0.0175 | 49.11 | 0.72 | 1.58 |

| 40 | 0.17 | 0.0066 | 0.465 | 0.0183 | 53.62 | 0.57 | 1.27 |

| 40 | 0.15 | 0.0059 | 0.485 | 0.0190 | 58.33 | 0.45 | 0.99 |

| 40 | 0.13 | 0.0051 | 0.505 | 0.0198 | 63.24 | 0.33 | 0.74 |

| 40 | 0.12 | 0.0047 | 0.515 | 0.0202 | 65.77 | 0.28 | 0.63 |

| 50 | 0.25 | 0.0098 | 0.258 | 0.0101 | 25.79 | 1.56 | 3.43 |

| 50 | 0.23 | 0.0090 | 0.278 | 0.0109 | 29.94 | 1.32 | 2.90 |

| 50 | 0.21 | 0.0082 | 0.298 | 0.0117 | 34.41 | 1.10 | 2.42 |

| 50 | 0.19 | 0.0074 | 0.318 | 0.0125 | 39.18 | 0.90 | 1.98 |

| 50 | 0.18 | 0.0070 | 0.328 | 0.0129 | 41.68 | 0.81 | 1.78 |

| 50 | 0.17 | 0.0066 | 0.338 | 0.0133 | 44.26 | 0.72 | 1.58 |

| 50 | 0.15 | 0.0059 | 0.358 | 0.0140 | 49.66 | 0.56 | 1.23 |

| 50 | 0.13 | 0.0051 | 0.378 | 0.0148 | 55.36 | 0.42 | 0.92 |

| 50 | 0.12 | 0.0047 | 0.388 | 0.0152 | 58.33 | 0.36 | 0.79 |

| 60 | 0.23 | 0.0090 | 0.193 | 0.0076 | 20.85 | 1.58 | 3.49 |

| 60 | 0.21 | 0.0082 | 0.213 | 0.0083 | 25.39 | 1.32 | 2.91 |

| 60 | 0.19 | 0.0074 | 0.233 | 0.0091 | 30.38 | 1.08 | 2.37 |

| 60 | 0.17 | 0.0066 | 0.253 | 0.0099 | 35.81 | 0.86 | 1.90 |

| 60 | 0.15 | 0.0059 | 0.273 | 0.0107 | 41.68 | 0.67 | 1.47 |

| 60 | 0.13 | 0.0051 | 0.293 | 0.0115 | 48.01 | 0.50 | 1.11 |

| 60 | 0.12 | 0.0047 | 0.303 | 0.0119 | 51.34 | 0.43 | 0.95 |

| 80 | 0.13 | 0.0051 | 0.187 | 0.0073 | 34.87 | 0.67 | 1.48 |

| 80 | 0.12 | 0.0047 | 0.197 | 0.0077 | 38.69 | 0.57 | 1.25 |

| 80 | 0.10 | 0.0039 | 0.217 | 0.0085 | 46.92 | 0.40 | 0.88 |

| 80 | 0.09 | 0.0035 | 0.227 | 0.0089 | 51.34 | 0.32 | 0.71 |

| 100 | 0.10 | 0.0039 | 0.154 | 0.0060 | 36.75 | 0.50 | 1.10 |

| 100 | 0.08 | 0.0031 | 0.174 | 0.0068 | 46.92 | 0.32 | 0.70 |

| 120 | 0.09 | 0.0035 | 0.121 | 0.0047 | 33.03 | 0.48 | 1.06 |

| 120 | 0.08 | 0.0031 | 0.131 | 0.0051 | 38.69 | 0.38 | 0.83 |

| 120 | 0.07 | 0.0027 | 0.141 | 0.0055 | 44.79 | 0.29 | 0.64 |

| 120 | 0.06 | 0.0023 | 0.151 | 0.0059 | 51.34 | 0.21 | 0.47 |

| 120 | 0.05 | 0.0019 | 0.161 | 0.0063 | 58.33 | 0.15 | 0.33 |

| 150 | 0.06 | 0.0023 | 0.109 | 0.0043 | 41.68 | 0.27 | 0.59 |

| 150 | 0.065 | 0.0025 | 0.104 | 0.0041 | 37.96 | 0.31 | 0.69 |

| 165 | 0.063 | 0.0024 | 0.090 | 0.0035 | 34.89 | 0.32 | 0.72 |

| 165 | 0.06 | 0.0023 | 0.093 | 0.0036 | 37.23 | 0.29 | 0.65 |

| 165 | 0.05 | 0.0019 | 0.103 | 0.0040 | 45.58 | 0.20 | 0.45 |

| 180 | 0.05 | 0.0019 | 0.091 | 0.0035 | 41.68 | 0.22 | 0.48 |

| 200 | 0.05 | 0.0019 | 0.077 | 0.0030 | 36.75 | 0.25 | 0.55 |

| 200 | 0.04 | 0.0015 | 0.087 | 0.0034 | 46.93 | 0.16 | 0.35 |

| 250 | 0.04 | 0.0015 | 0.061 | 0.0024 | 36.75 | 0.20 | 0.44 |

| 300 | 0.04 | 0.0015 | 0.044 | 0.0017 | 27.83 | 0.24 | 0.52 |

Twill Weave Mesh Specifications:

| Mesh | Wire D | Aperture L | Open Area | Square Meter Weight | |||

| openings/inch | mm | inch | mm | inch | % | kgs | lbs |

| 40 | 0.30 | 0.0118 | 0.335 | 0.0131 | 27.83 | 1.80 | 3.96 |

| 40 | 0.27 | 0.0106 | 0.365 | 0.0143 | 33.03 | 1.45 | 3.20 |

| 40 | 0.25 | 0.0098 | 0.385 | 0.0151 | 36.75 | 1.25 | 2.75 |

| 40 | 0.23 | 0.0090 | 0.405 | 0.0159 | 40.67 | 1.05 | 2.31 |

| 40 | 0.21 | 0.0082 | 0.425 | 0.0167 | 44.79 | 0.88 | 1.94 |

| 40 | 0.19 | 0.0074 | 0.445 | 0.0175 | 49.11 | 0.72 | 1.58 |

| 40 | 0.17 | 0.0066 | 0.465 | 0.0183 | 53.62 | 0.57 | 1.27 |

| 40 | 0.15 | 0.0059 | 0.485 | 0.0190 | 58.33 | 0.45 | 0.99 |

| 50 | 0.25 | 0.0098 | 0.258 | 0.0101 | 25.79 | 1.56 | 3.43 |

| 50 | 0.23 | 0.0090 | 0.278 | 0.0109 | 29.94 | 1.32 | 2.90 |

| 50 | 0.21 | 0.0082 | 0.298 | 0.0117 | 34.41 | 1.10 | 2.42 |

| 50 | 0.19 | 0.0074 | 0.318 | 0.0125 | 39.18 | 0.90 | 1.98 |

| 50 | 0.18 | 0.0070 | 0.328 | 0.0129 | 41.68 | 0.81 | 1.78 |

| 50 | 0.17 | 0.0066 | 0.338 | 0.0133 | 44.26 | 0.72 | 1.58 |

| 50 | 0.15 | 0.0059 | 0.358 | 0.0140 | 49.66 | 0.56 | 1.23 |

| 60 | 0.23 | 0.0090 | 0.193 | 0.0076 | 20.85 | 1.58 | 3.49 |

| 60 | 0.21 | 0.0082 | 0.213 | 0.0083 | 25.39 | 1.32 | 2.91 |

| 60 | 0.19 | 0.0074 | 0.233 | 0.0091 | 30.38 | 1.08 | 2.37 |

| 60 | 0.17 | 0.0066 | 0.253 | 0.0099 | 35.81 | 0.86 | 1.90 |

| 60 | 0.15 | 0.0059 | 0.273 | 0.0107 | 41.68 | 0.67 | 1.47 |

| 60 | 0.13 | 0.0051 | 0.293 | 0.0115 | 48.01 | 0.50 | 1.11 |

| 60 | 0.12 | 0.0047 | 0.303 | 0.0119 | 51.34 | 0.43 | 0.95 |

| 80 | 0.15 | 0.0059 | 0.167 | 0.0065 | 27.83 | 0.9 | 1.98 |

| 80 | 0.18 | 0.0070 | 0.137 | 0.0054 | 18.75 | 1.29 | 2.85 |

| 80 | 0.13 | 0.0051 | 0.187 | 0.0073 | 34.87 | 0.67 | 1.48 |

| 80 | 0.12 | 0.0047 | 0.197 | 0.0077 | 38.69 | 0.57 | 1.25 |

| 80 | 0.10 | 0.0039 | 0.217 | 0.0085 | 46.92 | 0.40 | 0.88 |

| 100 | 0.10 | 0.0039 | 0.154 | 0.0060 | 36.75 | 0.50 | 1.10 |

| 100 | 0.14 | 0.0055 | 0.114 | 0.0044 | 20.14 | 0.98 | 2.15 |

| 100 | 0.12 | 0.0047 | 0.134 | 0.0052 | 27.83 | 0.72 | 1.58 |

| 120 | 0.12 | 0.0047 | 0.091 | 0.0036 | 18.75 | 0.86 | 1.90 |

| 120 | 0.10 | 0.0039 | 0.111 | 0.0043 | 27.83 | 0.6 | 1.32 |

| 120 | 0.09 | 0.0035 | 0.121 | 0.0047 | 33.03 | 0.48 | 1.06 |

| 120 | 0.08 | 0.0031 | 0.131 | 0.0051 | 38.69 | 0.38 | 0.83 |

| 150 | 0.08 | 0.0031 | 0.089 | 0.0035 | 27.83 | 0.48 | 1.05 |

| 150 | 0.07 | 0.0027 | 0.099 | 0.0039 | 34.41 | 0.36 | 0.80 |

| 150 | 0.06 | 0.0023 | 0.109 | 0.0043 | 41.68 | 0.27 | 0.59 |

| 180 | 0.065 | 0.0026 | 0.076 | 0.0030 | 29.47 | 0.38 | 0.83 |

| 180 | 0.06 | 0.0023 | 0.081 | 0.0031 | 33.03 | 0.32 | 0.71 |

| 180 | 0.05 | 0.0019 | 0.091 | 0.0035 | 41.68 | 0.22 | 0.48 |

| 200 | 0.05 | 0.0019 | 0.077 | 0.0030 | 36.75 | 0.25 | 0.55 |

| 200 | 0.06 | 0.0023 | 0.067 | 0.0026 | 27.83 | 0.36 | 0.79 |

| 250 | 0.05 | 0.0019 | 0.051 | 0.0020 | 25.79 | 0.31 | 0.68 |

| 250 | 0.04 | 0.0015 | 0.061 | 0.0024 | 36.75 | 0.20 | 0.44 |

| 300 | 0.04 | 0.0015 | 0.044 | 0.0017 | 27.83 | 0.24 | 0.52 |

| 325 | 0.035 | 0.0013 | 0.043 | 0.0016 | 30.48 | 0.19 | 0.41 |

| 325 | 0.04 | 0.0015 | 0.038 | 0.0015 | 23.83 | 0.26 | 0.57 |

| 400 | 0.03 | 0.0011 | 0.033 | 0.0013 | 27.83 | 0.18 | 0.39 |

| 500 | 0.025 | 0.0009 | 0.025 | 0.0010 | 25.79 | 0.15 | 0.33 |

| 600 | 0.018 | 0.0007 | 0.024 | 0.0009 | 33.03 | 0.09 | 0.21 |

| 635 | 0.015 | 0.0005 | 0.025 | 0.0009 | 39.06 | 0.07 | 0.15 |

Other specifications according to your requirements.

![]()

![]()

Materials:

201, 304, 304L, 316, 316L

Features:

Corrosion Resistance: One of the most prominent features of stainless steel is its excellent resistance to corrosion. This is due to the presence of chromium in the alloy, which forms a protective oxide layer on the surface of the material, preventing rust and corrosion.

Strength and Durability: Stainless steel is a strong and durable material that can withstand a wide range of environmental conditions and mechanical stresses. It is commonly used in applications where strength and longevity are essential.

Hygiene and Cleanliness: Stainless steel is non-porous, making it easy to clean and resistant to bacteria growth. This property makes it a popular choice for applications where hygiene is crucial, such as in the food and medical industries.

Aesthetic Appeal: Stainless steel has a modern and attractive appearance that fits well in various design styles. It is often used in architectural, interior design, and decorative applications.

Temperature Resistance: Stainless steel can withstand high and low temperatures without losing its mechanical properties, making it suitable for applications that involve extreme temperature conditions.

Recyclability: Stainless steel is a highly recyclable material, making it an environmentally friendly choice. It can be recycled and reused without losing its quality.

Versatility: Stainless steel is available in various grades and finishes to suit different applications. Common grades include 304 (most common), 316, 430, and more, each with specific properties for different uses.

Magnetic Properties: Some types of stainless steel are magnetic, while others are not. This property is important in applications where magnetic properties are a consideration.

Resistance to Staining: Stainless steel is resistant to staining and can maintain its appearance over time with proper care and maintenance.

Applications:

Widely used in stainless steel mesh screen filter and protective decorative, scope throughout the mining, petroleum, chemical, food, medicine, machinery manufacturing, construction, decoration, electronics, aerospace and other industries.

Packing:

![]()