-

SS Welded Wire Mesh

-

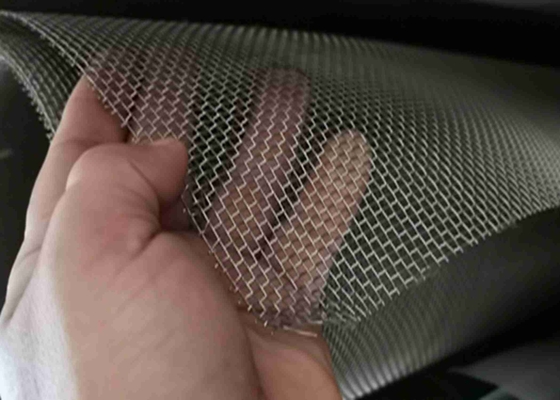

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Super Duplex 2507 Ss Woven Wire Mesh Corrosion Resistance

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Great Resistance To General Corrosion | Product Name | SS Woven Wire Mesh |

|---|---|---|---|

| Material | Super Duplex Stainless Steel 2507 | Surface | Bright Silver |

| Aperture Shape | Square | Mesh Size | 0.2mesh/inch To 300mesh/inch |

| Weaving Type | Plain Weave | Wire Diameter | 0.03mm To 8.0mm |

| Width | 0.1 To 1.5m | Application | Chemical Industry Filtration Applications, Oil And Chemical Plans, Pharmaceutical Plants And Food Processing Plants. |

| Highlight | 2507 ss woven wire mesh,corrosion resistance ss woven wire mesh,2507 stainless steel woven wire mesh |

||

Super Duplex Stainless Steel 2507 Mesh Great Resistance To General Corrosion

Duplex Stainless Steel Wire Mesh 2507 Introduction

Super Duplex Stainless Steel 2507(UNS S32750) Mesh and Wire Cloth is made of high quality super duplex wire. It is designed for applications that need exceptional durability and corrosion resistance. It has excellent performance in pitting and crevice conditions. Super Duplex Stainless Steel 2507 Mesh is resistant to chloride induced stress corrosion cracking. The application range for Duplex stainless 2507 mesh is limited to temperature under 600oF or 316oC. This steel grade is highly resistant to attack in organic acid media involving formic and acetic acid as well as inorganic acids containing chlorides.

2507 Duplex Stainless Steel Mesh Chemistry:

|

Cr |

Ni |

Mo |

C |

N |

Mn |

Si |

Cu |

P |

S |

Fe |

|

24-26 % |

6-8 % |

3-5 % |

0.030 % |

0.24 – 0.32 % |

1.20 % |

0.80 % |

0.50 % |

0.035 % |

0.020 % |

Bal |

Specifications:

Woven Style: Plain and Twill Weave

Mesh Counts: 3-500Mesh

Diameter: 0.025mm-2.2mm

Roll Width: 0.1-1.5m

Roll Length: 10-100m

| Mesh Inch | SWG |

Wire Diameter (mm) |

Aperture (mm) |

Effective (%) |

| 3mesh | 14 | 2.2 | 6.27 | 62 |

| 3mesh | 18 | 1.219 | 7.25 | 70 |

| 3.5mesh | 20 | 0.914 | 6.34 | 66 |

| 4mesh | 16 | 1.63 | 4.72 | 58 |

| 4mesh | 20 | 0.914 | 5.45 | 76 |

| 4.5mesh | 22 | 0.711 | 4.93 | 71 |

| 5mesh | 18 | 1.22 | 3.86 | 57 |

| 5mesh | 22 | 0.711 | 4.36 | 76 |

| 6mesh | 18 | 1.22 | 3.04 | 50 |

| 6mesh | 22 | 0.711 | 3.52 | 63 |

| 8mesh | 20 | 0.91 | 2.26 | 43 |

| 8mesh | 24 | 0.559 | 2.5 | 67 |

| 10mesh | 20 | 0.91 | 1.63 | 41 |

| 10mesh | 26 | 0.46 | 2.08 | 67 |

| 12mesh | 22 | 0.71 | 1.41 | 43 |

| 12mesh | 26 | 0.457 | 1.74 | 68 |

| 14mesh | 26 | 0.46 | 1.36 | 57 |

| 16mesh | 28 | 0.376 | 1.21 | 55 |

| 18mesh | 30 | 0.315 | 1.1 | 60 |

| 20mesh | 30 | 0.315 | 0.95 | 58 |

| 22mesh | 32 | 0.274 | 0.88 | 57 |

| 24mesh | 32 | 0.274 | 0.78 | 55 |

| 26mesh | 32 | 0.274 | 0.74 | 51 |

| 28mesh | 34 | 0.234 | 0.67 | 50 |

| 30mesh | 34 | 0.234 | 0.61 | 48 |

| 32mesh | 34 | 0.234 | 0.56 | 50 |

| 36mesh | 34 | 0.234 | 0.47 | 45 |

| 38mesh | 36 | 0.193 | 0.48 | 46 |

| 40mesh | 36 | 0.193 | 0.44 | 50 |

| 50mesh | 38 | 0.152 | 0.36 | 46 |

| 60mesh | 40 | 0.122 | 0.3 | 50 |

| 80mesh | 40 | 0.12 | 0.198 | 44 |

| 100mesh | 42 | 0.1 | 0.154 | 37 |

| 120mesh | 44 | 0.081 | 0.13 | 40 |

| 130mesh | 45 | 0.07 | 0.125 | 41 |

| 140mesh | 45 | 0.07 | 0.111 | 38 |

| 150mesh | 46.5 | 0.055 | 0.115 | 48 |

| 160mesh | 46 | 0.61 | 0.097 | 32 |

| 170mesh | 47 | 0.05 | 0.09 | 41 |

| 180mesh | 47 | 0.051 | 0.09 | 410 |

| 190mesh | 47 | 0.051 | 0.083 | 40 |

| 200mesh | 48 | 0.041 | 0.086 | 46 |

| 220mesh | 48 | 0.041 | 0.074 | 41 |

| 240mesh | 48 | 0.041 | 0.065 | 39 |

| 250mesh | 48 | 0.041 | 0.061 | 38 |

| 260mesh | 48 | 0.041 | 0.057 | 34 |

| 280mesh | 49 | 0.031 | 0.06 | 31 |

| 300mesh | 49 | 0.031 | 0.054 | 40 |

Other specifications according to your request.

![]()

2507 Duplex Stainless Steel Mesh Available Types:

![]()

2507 Duplex Stainless Steel Mesh Property Data:

|

Temp |

20oC |

100oC |

200oC |

300oC |

|

Property |

||||

|

Density |

7.8 |

|

|

|

|

Modulus of elasticity |

200 |

194 |

186 |

180 |

|

Poissons ratio |

0.3 |

|

|

|

|

Linear thermal expansion |

– |

13 |

13.5 |

14 |

|

Thermal conductivity |

15 |

16 |

17 |

18 |

|

Thermal capacity |

500 |

530 |

560 |

5.90 |

|

Electric resistivity |

0.80 |

0.85 |

0.90 |

1 |

Super Duplex Stainless Steel 2507 Mechanical Properties:

| 0.2% Offset Yield Strength | 80 ksi |

| Ultimate Tensile Strength | 116 ksi |

| 0.1% Offset Yield Strength 0.2% | 91 ksi |

| Elongation in 2 inches, % | 15 % |

| Hardness Rockwell C | 32 |

| Impact Energy | 74 ft.-lbs |

| Density | 0.28 lb per inch3 |

| Modulus of elasticity | 28 x 10(6) psi |

| Coefficient of thermal expansion | 7.2 x 10(-6) per of at 68 to 212 of |

| Thermal conductivity | 8.7 Btu/hr ftoF |

| Heat capacity | 0.12 Btu/ lb oF |

| Electrical resistivity | 31.5 x10(-6) ohm-inch |

Features:

Outstanding corrosion resistance

Resistance to pitting and crevice corrosion

Withstands fluctuating temperatures

High mechanical properties

Resistance to localized corrosion

Applications:

Chemical industry filtration applications, Oil and chemical plans, pharmaceutical plants and food processing plants.

Packing:

![]()