-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

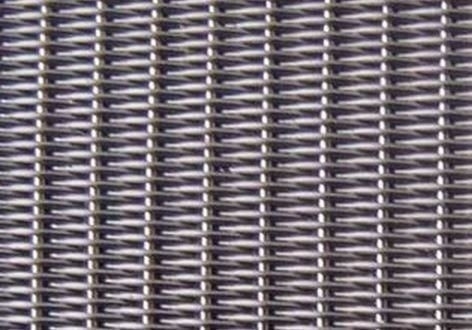

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Stainless Steel Dutch Weave Wire Mesh Highly Durable Fine Filtration

| Place of Origin | Anping of China |

|---|---|

| Brand Name | QIANPU |

| Certification | ISO |

| Minimum Order Quantity | 1 roll |

| Price | Negotiable according to quantity of order |

| Packaging Details | 1. inside use carton pipe for support+wire mesh layer+water proof paper 2. outside use plastic wooden bags+wooden case/carton pipes/wooden pallets. 3. also we can as per your requirements. |

| Supply Ability | 3000 rolls per month |

| Features | Highly Durable Fine Filtration | Product Name | Stainless Steel Dutch Wire Mesh |

|---|---|---|---|

| Material | Stainless Steel 304 316 | Cert | ISO9001 |

| Width | 0.1 To 2.0m | Length | 30m Or Customized |

| Color | Silver | Application | Filtering |

| Highlight | Highly Durable Stainless Wire Mesh,Stainless Dutch Weave Wire Mesh,Filtration stainless dutch wire mesh |

||

Stainless Steel Dutch Weave Wire Mesh, Highly Durable Fine Filtration

Stainless Steel Hollander Weave Wire Mesh

Dutch Weave Wire Mesh is made with relatively thin weft wires packed closely together, and thicker more widely spaced warp wires. It resembles a ‘basket’ weave and does not have square apertures. Dimensionally very stable and having high bursting strength, it is suitable for pressure filtration where a large open area is not required. Dutch weave wire cloth can be woven in plain dutch, twill dutch, reverse plain dutch format, reverse twill dutch format, in Stainless Steel and Mild Steel.

Specifications:

| Plain Dutch Weave | |||

|

Mesh/Inch (Warp x Weft) |

Wire Diameter (mm) (Warp x Weft) |

Filtration Fineness (um) (Warp x Weft) |

Weight (kg/sq.m) |

| 8x62 | 0.63x0.45 | 300 | 5.42 |

| 10x79 | 0.50x0.35 | 250 | 3.16 |

| 12x64 | 0.50x0.40 | 280 | 3.2 |

| 14x88 | 0.40x0.30 | 220 | 2.5 |

| 15x100 | 0.40x0.27 | 210 | 2.35 |

| 20x120 | 0.30x0.23 | 160 | 1.9 |

| 24x110 | 0.35x0.25 | 150 | 2.35 |

| 24x140 | 0.27x0.19 | 110 | 1.7 |

| 30x150 | 0.25x0.17 | 80 | 1.55 |

| 30x180 | 0.25x0.15 | 70 | 1.4 |

| 40x200 | 0.19x0.13 | 60 | 1.2 |

| 50x250 | 0.15x0.11 | 50 | 0.95 |

| 60x300 | 0.13x0.09 | 45 | 0.75 |

| 70x350 | 0.12x0.08 | 35 | 0.7 |

| 80x400 | 0.12x0.07 | 34 | 0.7 |

| 70x500 | 0.12x0.06 | 32 | 0.65 |

| 100x600 | 0.10x0.05 | 30 | 0.6 |

| Dutch Twilled Weave | |||

|

Mesh/Inch (Warp x Weft) |

Wire Diameter (mm) (Warp x Weft) |

Filtration Fineness (um) (Warp x Weft) |

Weight (kg/sq.m) |

| 20x200 | 0.335x0.28 | 118 | 4.58 |

| 20x260 | 0.25x0.20 | 119 | 3.14 |

| 24x300 | 0.28x0.18 | 110 | 3.01 |

| 30x250 | 0.28x0.20 | 77 | 3.41 |

| 30x340 | 0.28x0.16 | 89 | 2.84 |

| 40x560 | 0.18x0.10 | 70 | 1.73 |

| 80x700 | 0.12x0.08 | 30 | 1.26 |

| 80x780 | 0.12x0.07 | 28 | 1.22 |

| 90x780 | 0.10x0.07 | 26 | 1.24 |

| 100x780 | 0.10x0.07 | 25 | 1.13 |

| 120x1100 | 0.07x0.05 | 18 | 0.86 |

| 165x800 | 0.07x0.05 | 25 | 0.58 |

| 165x1400 | 0.07x0.04 | 14 | 0.75 |

| 200x600 | 0.06x0.04 | 28 | 0.5 |

| 200x1400 | 0.06x0.04 | 12 | 0.72 |

| 200x1600 | 0.06x0.035 | 11 | 0.7 |

| 200x1800 | 0.06x0.03 | 10 | 0.7 |

| 250x2000 | 0.045x0.028 | 8 | 0.65 |

| 325x2300 | 0.035x0.026 | 5 | 0.57 |

| 325x2500 | 0.035x0.023 | 4 | 0.52 |

| 400x2800 | 0.03x0.018 | 3 | 0.46 |

| 400x3000 | 0.03x0.16 | 2. | 0.43 |

| 400x3500 | 0.03x0.15 | 1 | 0.38 |

| Reverse Dutch Weave | ||||

|

Mesh/Inch (Warp x Weft) |

Wire Diameter(mm) (Warp x Weft) |

Wire Diameter(inch) (Warp x Weft) |

Open Area % | Absolute Filter rating(um) |

| 63 x 18 | 0.40 x 0.60 | 0.0157 x 0.0236 | 60 | 220 |

| 107x20 | 0.24 x 0.60 | 0.0094 x 0.0236 | 58 | 210 |

| 72 x 15 | 0.45 x 0.55 | 0.0177 x 0.0216 | 60 | 200 |

| 152x24 | 0.30 x 0.40 | 0.0118 x 0.0157 | 56 | 160 |

| 170x40 | 0.20 x 0.45 | 0.0079 x 0.0177 | 58 | 130 |

| 132x32 | 0.20 x 0.40 | 0.0079 x 0.0157 | 55 | 105 |

| 171x46 | 0.15 x 0.30 | 0.0059 x 0.0118 | 54 | 85 |

| 290x75 | 0.09 x 0.20 | 0.0035 x 0.0079 | 53 | 55 |

| 615x102 | 0.04 x 0.16 | 0.0157 x 0.0063 | 41 | 42 |

| 615x130 | 0.04 x 0.13 | 0.0157 x 0.0051 | 49 | 22 |

| 720x150 | 0.036 x 0.10 | 0.0014 x 0.0039 | 54 | 17 |

Features:

This kind of woven wire mesh is strong woven product, is fine filtration and highly durable, offers good wear-resistance, heat-resistance, acid-resistance and corrosion resistance. With following characteristics: High accuracy, Nominal or no pressure loss while filtration, Supreme filtration surface, More stable than square and rectangular wire mesh.

Main Material: Stainless Steel 304, 304L, 316, 316L, etc.

Weaving methods: Plain Dutch Weave, Twill Dutch Weave, Reverse Dutch Weave

![]()

Warp: The wires running lengthwise in the mesh.

Weft (or Shute): The wires running transversely across the mesh.

Application:

Hollander woven stainless steel wire cloth offers finer filtration and finds popular application in petroleum, chemical, food, pharmacy and other fields. Through constant technological innovation and improvement, we can produce stainless steel wire mesh of various specification in duch/reverse dutch weaving patterns. Applications of Reverse Woven Wire Cloth: Filter candles, vacuum filters and spring filters.

![]()

Packing:

![]()