-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

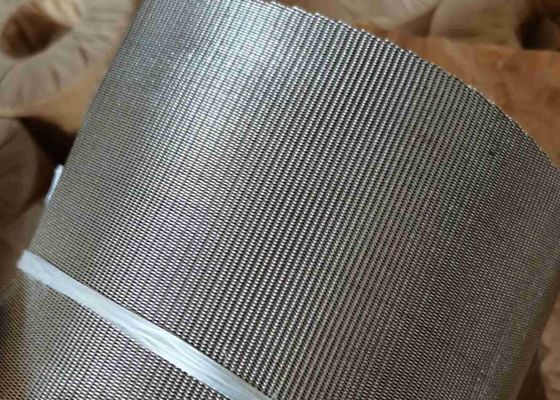

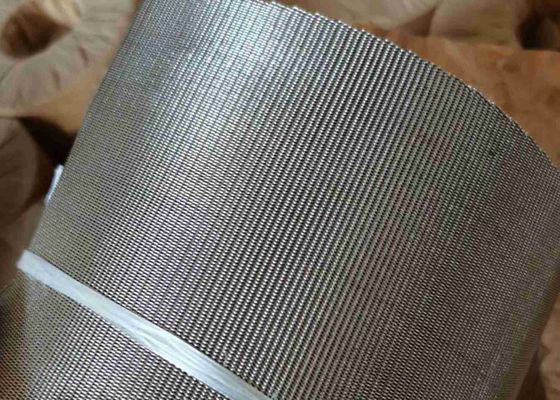

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

ASTM Stainless Steel Wire Screen

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Significantly Higher Particle Separation | Product Name | Stainless Steel Dutch Wire Mesh |

|---|---|---|---|

| Standard | ASTM, AISI, DIN, SUS | Minimum Aperture | 3 μm |

| Mesh Counts | 500 × 3500 | Minimum Wire | 0.025mm ×0.015mm |

| Weaving Type | Plain Dutch Weave, Twill Dutch Weave | Roll Width | Up To 120" |

| Roll Length | Up To 800' | Application | Commonly Used In Auto Screen Changers Used In The Plastic Extrusion Industry |

| Highlight | TENGLU ASTM Stainless Steel Wire Screen,TENGLU AISI Stainless Steel Wire Screen,TENGLU AISI SUS stainless wire mesh screen |

||

Plain Dutch Weave and Twill Dutch Weave ASTM Standard Stainless Steel Dutch Wire Mesh

Introduction:

We manufacture custom woven wire cloth to meet clients’ filtration needs. Dutch weave filter mesh provides superior filtration capabilities for a wide range of applications including, pressure, fuel and liquid filters for aerospace, petrochemical, pharmaceutical, mining, and waste water treatment industries.

Twill Dutch weave woven wire cloth combines Dutch and twill weaving to provide a fine mesh filtering cloth. Shute wires are passed over and under two warp wires, providing a tight, fine filter with tapered openings. The weaving process allows for the use of very fine wires, produce filtering mesh for gas and liquid applications.

Reverse Dutch weave woven wire cloth is woven using two sizes of wire. Smaller wires are used in the warp direction and are woven with a larger shute wire. The smaller wires are woven tightly together, providing a tight mesh for filtering. The larger wire provides strength to the mesh. The primary uses of this woven wire cloth are filtration and separation of liquid and slurry products. Reverse Twill Dutch weave woven wire cloth combines Dutch and twill weaving to provide a fine mesh filtering cloth. The weaving process allows for the use of very fine wires, producing filtering mesh for gas and liquid applications. We also provide Herringbone and Broken Pattern Reverse Twill Dutch Weave Products.

A full range of conversion services are available. These include slitting, shearing, annealing and stretching. We can also provide information on the filtration performance of the mesh to ensure it meets product requirements.

Plain Dutch and Twill Dutch weave woven wire cloth products are in compliance with ISO 9001:2015 and ASTM standards. We offer a wide range of metals and alloys to provide the best material or combination of materials for the filter mesh. Most are available in DFARS-compliant materials. We also manufacture to ISO, DIN and client requirements. Our expert staff is available to help you select or design the most effective wire cloth product for your application.

Plain Dutch Weave Wire Mesh Specifications:

|

Mesh Counts warp×weft (Mesh/Inch) |

Wire Diameter warp×weft (mm) |

Aperture Size (μm) |

Weight (kg/㎡) |

Thickness (mm) |

| 7×40 | 0.9×0.71 | 347 | 6.65 | 2.32 |

| 7×44 | 0.71×0.63 | 319 | 5.55 | 1.97 |

| 8×45 | 0.8×0.6 | 310 | 5.7 | 2.00 |

| 8.5×60 | 0.63×0.45 | 296 | 4.16 | 1.53 |

| 8×85 | 0.45×0.315 | 275 | 2.73 | 1.08 |

| 10×90 | 0.45×0.28 | 249 | 2.57 | 1.01 |

| 10×76 | 0.5×0.355 | 248 | 3.24 | 1.21 |

| 12×86 | 0.45×0.315 | 211 | 2.93 | 1.08 |

| 12×64 | 0.56×0.4 | 3.89 | 1.36 | |

| 12.5×76 | 0.45×0.355 | 192 | 3.26 | 1.16 |

| 14×100 | 0.40×0.28 | 182 | 2.62 | 0.96 |

| 14×110 | 0.355×.0.25 | 177 | 2.28 | 0.855 |

| 14×76 | 0.45×.0.355 | 173 | 3.33 | 1.16 |

| 16×100 | 0.4×0.28 | 160 | 2.7 | 0.96 |

| 17×120 | 0.355×0.224 | 155 | 2.19 | 0.803 |

| 16×120 | 0.28×0.224 | 145 | 1.97 | 0.728 |

| 20×140 | 0.315×0.20 | 133 | 0.715 | |

| 20×170 | 0.25×0.16 | 130 | 1.56 | 0.57 |

| 20×110 | 0.355×0.25 | 126 | 2.47 | 0.855 |

| 22×120 | 0.315×0.224 | 115 | 2.20 | 0.763 |

| 25×140 | 0.28×0.2 | 100 | 1.96 | 0.68 |

| 24×110 | 0.355×0.25 | 97 | 2.60 | 0.855 |

| 28×150 | 0.28×0.18 | 92 | 1.87 | 0.64 |

| 30×150 | 0.25×0.18 | 82 | 1.79 | 0.61 |

| 30×140 | 0.315×0.20 | 77 | 2.21 | 0.715 |

| 35×190 | 0.224×0.14 | 74 | 1.47 | 0.504 |

| 35×170 | 0.224×0.16 | 69 | 1.62 | 0.544 |

| 40×200 | 0.18×0.135 | 63 | 1.24 | 0.43 |

| 45×250 | 0.16×0.11 | 56 | 1.11 | 0.384 |

| 50×300 | 0.16×0.09 | 55 | 0.98 | 0.34 |

| 60×500 | 0.14×0.055 | 51 | 0.70 | 0.252 |

| 50×270 | 0.14×0.10 | 50 | 0.98 | 0.34 |

| 70×930 | 0.10×0.03 | 30 | 0.39 | 0.16 |

| 65×390 | 0.125×0.071 | 42 | 0.78 | 0.267 |

| 60×300 | 0.14×0.09 | 41 | 0.96 | 0.32 |

| 80×700 | 0.125×0.04 | 40 | 0.60 | 0.205 |

| 60×270 | 0.14×0.1 | 39 | 1.03 | 0.34 |

| 77×560 | 0.14×0.05 | 38 | 0.74 | 0.24 |

| 80×600 | 0.1×0.045 | 37 | 0.53 | 0.19 |

| 70×390 | 0.112×0.071 | 0.74 | 0.254 | |

| 65×750 | 0.10×0.036 | 36 | 0.43 | 0.172 |

| 70×340 | 0.125×0.08 | 35 | 0.86 | 0.285 |

| 80×430 | 0.125×0.063 | 32 | 0.77 | 0.251 |

| 100×1200 | 0.063×0.023 | 23 | 0.27 | 0.109 |

| 118×750 | 0.063×0.036 | 0.38 | 0.135 |

Twill Dutch Weave Wire Mesh Specifications:

| Mesh (mesh/inch) Warp×Weft |

Warp×Weft (mm) |

Aperture Size (um) |

Available Area(%) |

Thickness (mm) |

| 20×150 | 0.45×0.355 | 101 | 7.5 | 1.16 |

| 20×200 | 0.355×0.28 | 118 | 12.1 | 0.915 |

| 20×250 | 0.25×0.15 | 120 | 17 | 0.71 |

| 20×270 | 0.25×0.20 | 119 | 17.6 | 0.65 |

| 24×300 | 0.28×0.18 | 110 | 19.6 | 0.64 |

| 30×270 | 0.28×0.20 | 77 | 11.2 | 0.68 |

| 30×300 | 0.25×0.18 | 38 | ||

| 30×340 | 0.28×0.16 | 89 | 17.9 | 0.60 |

| 30×360 | 0.25×0.15 | |||

| 40×430 | 0.18×0.125 | 63 | 15.4 | 0.43 |

| 40×540 | 0.18×0.10 | 70 | 23.5 | 0.38 |

| 50×500 | 0.14×0.11 | 47 | 12 | 0.364 |

| 50×600 | 0.125×0.09 | 51 | 17.2 | 0.305 |

| 65×600 | 0.14×0.09 | 36 | 12 | 0.32 |

| 70×600 | 0.14×0.09 | 31 | 10.1 | 0.32 |

| 78×680 | 0.112×0.08 | 29 | 10.3 | 0.272 |

| 78×760 | 0.112×0.071 | 31 | 13.5 | 0.254 |

| 80×680 | 0.112×0.08 | 28 | 9.8 | 0.272 |

| 80×700 | 0.11×0.08 | - | - | - |

| 90×760 | 0.10×0.071 | 24 | 9.6 | 0.242 |

| 90×780 | 0.11×0.07 | - | - | - |

| 90×850 | 0.10×0.063 | 26 | 12.7 | 0.226 |

| 100×760 | 0.10×0.071 | 20 | 7.4 | 0.242 |

| 100×850 | 0.10×0.063 | 22 | 10 | 0.226 |

| 130×1100 | 0.071×0.05 | 17 | 9.4 | 0.171 |

| 130×1200 | 0.071×0.045 | 18 | 12 | 0.161 |

| 130×1500 | 0.063×0.036 | 21 | 18.6 | 0.135 |

| 150×1400 | 0.063×0.04 | 15 | 11.4 | 0.143 |

| 160×1500 | 0.063×0.036 | 15 | 12.4 | 0.135 |

| 165×800 | 0.07×0.05 | - | - | - |

| 165×1400 | 0.063×0.04 | 13 | 8.8 | - |

| 165×1500 | 0.063×0.036 | 14 | 11.4 | 0.135 |

| 174×1400 | 0.063×0.04 | 11 | 7.4 | 0.143 |

| 174×1700 | 0.063×0.032 | 13 | 12.9 | 0.127 |

| 203×1500 | 0.056×0.036 | 9 | 6 | - |

| 203×1600 | 0.05×0.032 | 10 | 9.3 | 0.114 |

| 216×1800 | 0.045×0.03 | - | 9 | 0.105 |

| 250×1600 | 0.05×0.032 | - | 4 | - |

| 250×1900 | 0.04×0.028 | 8 | 8 | - |

| 285×2100 | 0.036×0.025 | 7 | 7.2 | - |

| 300×2100 | 0.036×0.025 | 6 | 6 | - |

| 317×2100 | 0.036×0.025 | 5 | 5 | - |

| 325×2300 | 0.036×0.024 | 4 | 4 | - |

| 363×2300 | 0.032×0.022 | - | 5 | - |

| 400×2700 | 0.028×0.02 | - | 5 | |

| 400×2800 | 0.028×0.02 | 4 | - | - |

| 500×3500 | 0.025×0.015 | 3 | 4.9 | 0.055 |

| Note: Absolute filter values above should be taken as just rough estimations. | ||||

Other specifications customed as your requests.

![]()

Features:

Excellent filtration performance;

Acid resistance;

High temperature resistance;

Tensil and abrasion resistence;

Stability of filtration;

Fine and high precision

Uses of wire mesh include:

Sizing

Particle separation and filtering

Particulate sifting

ety and equipment protection.

Industries served include aerospace, automotive, construction and oil & gas.

Packing:

![]()

Questions: What specs are needed to quote?

Answer: Material, woven type, aperture or mesh counts, wire diameter, roll width x roll length and number of rolls.