-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

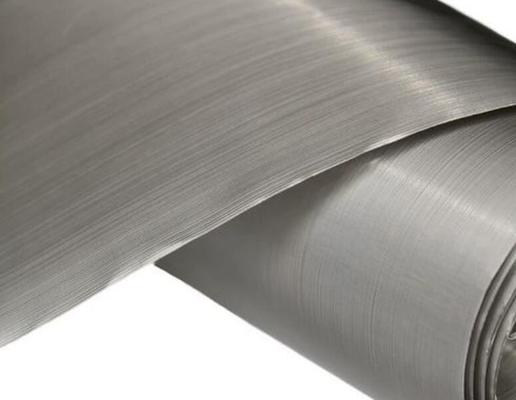

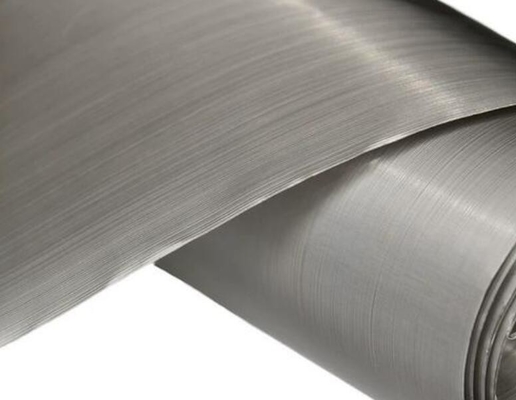

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Plain Dutch Wire Mesh High Filtration Efficiency Durability Ability To Withstand High Pressure And Mechanical Stress

| Place of Origin | Anping of China |

|---|---|

| Brand Name | QIANPU |

| Certification | ISO |

| Minimum Order Quantity | 1 roll |

| Price | Negotiable according to quantity of order |

| Packaging Details | 1. inside use carton pipe for support+wire mesh layer+water proof paper 2. outside use plastic wooden bags+wooden case/carton pipes/wooden pallets. 3. also we can as per your requirements. |

| Delivery Time | 2weeks |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 3000 rolls per month |

| Product Name | Stainless Steel Plain Dutch Weave Mesh | Material | Stainless Steel 304 316 |

|---|---|---|---|

| Standard | AISI, DIN, SUS, Etc | Woven Type | Plain Dutch, Twill Dutch, Reverse Dutch |

| Mesh Count | 24x110 | Wire Diameter | 0.35x0.25 |

| Filtration Rating | 150 Micron | Color | Bright Silver |

| Feature | Corrosion Resistance | Application | Filtration Industry |

| Highlight | Mechanical Stress Dutch Wire Mesh,High Pressure Dutch Wire Mesh,High Filtration Efficiency Dutch Wire Mesh |

||

Plain Dutch Wire Mesh With High Filtration Efficiency, Durability, And Ability To Withstand High Pressure And Mechanical Stress

Introduction

"Plain Dutch weave wire mesh" is a specific type of Dutch weave wire mesh that is characterized by having a thick weft wire and a thin warp wire. In this weave pattern, the weft wires are closely spaced together, providing a tight filtration surface, while the warp wires are relatively thicker and are spaced further apart, adding strength to the mesh.

Plain Dutch weave wire mesh is known for its high filtration efficiency, durability, and ability to withstand high pressure and mechanical stress. It is commonly used in applications that require fine filtration and high mechanical strength, such as in the chemical, oil and gas, and aerospace industries.

Materials:

304,304L,316,316L Stainless steel wire, Nickel wire, Brass wire, Low-Carbon Steel wire and Special Alloy wire.

Features:

1. Warp wire has bigger dia than shute wire

2. Shute wires are possibly bound close to each other

3. High accuracy

4. Nominal or no pressure loss while filtration

5. Supreme filtration surface

6. More stable than square and rectangular wire mesh

Applications:

Our product maintains the highest quality standards and is ISO 9001:2015 certified. All of our wire mesh products can be supplied meeting ASTM standards. It is stocked in the several specifications to assure quick delivery.

We offer a broad range of plain Dutch weave mesh that is highly recommended for its large surface structure. The product has competency to obtain high flow levels and nominal pressure drop. These are commonly used for filter candles in edible oil refining, large mechanical loads for pre-coat filters, food and pharmaceutical filtration. We deliver the greater quality plain Dutch weave mesh that is highly reckoned in woven wire filter cloths.

Plain Dutch weave Specfications:

| Mesh Counts | Wire Diameter | Aperture Size | Weight | Thickness |

| warp×weft | warp×weft | (μm) | (kg/㎡) | (mm) |

| (Mesh/Inch) | (mm) | |||

| 7×40 | 0.9×0.71 | 347 | 6.65 | 2.32 |

| 7×44 | 0.71×0.63 | 319 | 5.55 | 1.97 |

| 8×45 | 0.8×0.6 | 310 | 5.7 | 2 |

| 8.5×60 | 0.63×0.45 | 296 | 4.16 | 1.53 |

| 8×85 | 0.45×0.315 | 275 | 2.73 | 1.08 |

| 10×90 | 0.45×0.28 | 249 | 2.57 | 1.01 |

| 10×76 | 0.5×0.355 | 248 | 3.24 | 1.21 |

| 12×86 | 0.45×0.315 | 211 | 2.93 | 1.08 |

| 12×64 | 0.56×0.4 | 3.89 | 1.36 | |

| 12.5×76 | 0.45×0.355 | 192 | 3.26 | 1.16 |

| 14×100 | 0.40×0.28 | 182 | 2.62 | 0.96 |

| 14×110 | 0.355×.0.25 | 177 | 2.28 | 0.855 |

| 14×76 | 0.45×.0.355 | 173 | 3.33 | 1.16 |

| 16×100 | 0.4×0.28 | 160 | 2.7 | 0.96 |

| 17×120 | 0.355×0.224 | 155 | 2.19 | 0.803 |

| 16×120 | 0.28×0.224 | 145 | 1.97 | 0.728 |

| 20×140 | 0.315×0.20 | 133 | 0.715 | |

| 20×170 | 0.25×0.16 | 130 | 1.56 | 0.57 |

| 20×110 | 0.355×0.25 | 126 | 2.47 | 0.855 |

| 22×120 | 0.315×0.224 | 115 | 2.2 | 0.763 |

| 25×140 | 0.28×0.2 | 100 | 1.96 | 0.68 |

| 24×110 | 0.355×0.25 | 97 | 2.6 | 0.855 |

| 28×150 | 0.28×0.18 | 92 | 1.87 | 0.64 |

| 30×150 | 0.25×0.18 | 82 | 1.79 | 0.61 |

| 30×140 | 0.315×0.20 | 77 | 2.21 | 0.715 |

| 35×190 | 0.224×0.14 | 74 | 1.47 | 0.504 |

| 35×170 | 0.224×0.16 | 69 | 1.62 | 0.544 |

| 40×200 | 0.18×0.135 | 63 | 1.24 | 0.43 |

| 45×250 | 0.16×0.11 | 56 | 1.11 | 0.384 |

| 50×300 | 0.16×0.09 | 55 | 0.98 | 0.34 |

| 60×500 | 0.14×0.055 | 51 | 0.7 | 0.252 |

| 50×270 | 0.14×0.10 | 50 | 0.98 | 0.34 |

| 70×930 | 0.10×0.03 | 30 | 0.39 | 0.16 |

| 65×390 | 0.125×0.071 | 42 | 0.78 | 0.267 |

| 60×300 | 0.14×0.09 | 41 | 0.96 | 0.32 |

| 80×700 | 0.125×0.04 | 40 | 0.6 | 0.205 |

| 60×270 | 0.14×0.1 | 39 | 1.03 | 0.34 |

| 77×560 | 0.14×0.05 | 38 | 0.74 | 0.24 |

| 80×600 | 0.1×0.045 | 37 | 0.53 | 0.19 |

| 70×390 | 0.112×0.071 | 0.74 | 0.254 | |

| 65×750 | 0.10×0.036 | 36 | 0.43 | 0.172 |

| 70×340 | 0.125×0.08 | 35 | 0.86 | 0.285 |

| 80×430 | 0.125×0.063 | 32 | 0.77 | 0.251 |

| 100×1200 | 0.063×0.023 | 23 | 0.27 | 0.109 |

| 118×750 | 0.063×0.036 | 0.38 | 0.135 |

![]()

Delivery Time

We always prepare enough stock material for your urgent requirement, the delivery time is 7 days for all the stock material. We'll check with our production department for the non-stock items to offer you the exact delivery time and producing schedule.

Mutual Benefit

If the products of our distributors are unmarketable due to the influence by market factors,we will seek customers in the same market or near market who are in need of the products to help the distributors to handle unsalable products.

![]()

Anping Qianpu Wire Mesh Products Co., Ltd.is a manufacture and exporter of stainless steel wire mesh product.

We are located in wire mesh industrial base Anping city,Hebei province in China.

Our product range is as below,

Stainless steel woven wire mesh

Welded wire mesh

Crimped wire mesh

Hexagonal wire mesh

Knitted wire mesh

Wire mesh filter

Window screen

![]()

![]()

![]()