-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

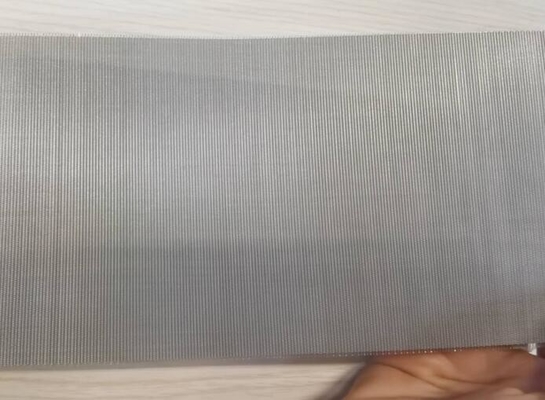

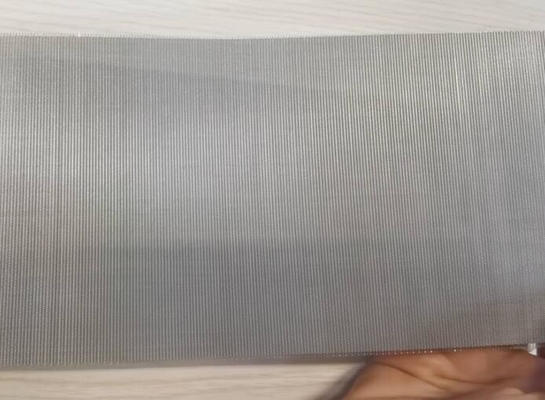

Reverse Dutch Woven Stainless Steel Cloth Extruder Screen Belt Durable High Tensile

| Features | Durable, Made Of High Tensile Stainless Steel Wire. | Product Name | Plain Dutch Wire Mesh |

|---|---|---|---|

| Material | Stainless Steel 302, 304, 316, 316L. | Mesh Counts | 48 × 10 Mesh, 72 × 15 Mesh, 132 × 14 Mesh, 132 × 17 Mesh, 152 × 24 Mesh, 152 × 30 Mesh, 260 × 40 Mesh, 250 × 40 Mesh, 400 × 120 Mesh. |

| Weaving Type | Reverse Dutch Woven | Roll Width | 100 Mm To 1200 Mm. |

| Roll Length | 10m, 20m, 30m,etc | Application | Filtration Industry |

| Highlight | Reverse Dutch Woven Stainless Steel Cloth,reverse dutch woven extruder screen,stainless steel cloth extruder screen |

||

Reverse Dutch Woven Stainless Steel Cloth Extruder Screen Belt Durableand High Tensile

Introduction:

In addition to extruder screen packs and extruder screen discs, we also can produce a wide range of extruder screen belt for continuous screen changers. The filter belt is produced in reverse dutch weaving type, so it can load greater strength in filtration. It is woven from high tensile stainless steel wire, and widely used in separating foreign particles out of molten plastic in plastic industries.

![]()

Characteristics:

1. Warp wire has bigger dia than shute wire

2. Shute wires are possibly bound close to each other

3. High accuracy

4. Nominal or no pressure loss while filtration

5. Supreme filtration surface

6. More stable than square and rectangular wire mesh

Features:

Durable, made of high tensile stainless steel wire.

Resistance to acid, soda, corrosion and high temperature.

Precise mesh size to ensure good filtration in extrusion.

Application:

Extruder screen belt is mainly used for belt style continuous screen changers in fine filtration and extrusion process, for example in plastic, rubber, petroleum, chemical, food and pharmacy industry.

Specification:

Material: stainless steel 302, 304, 316, 316L.

Wove type: reverse dutch weave pattern.

Size: 48 × 10 mesh, 72 × 15 mesh, 132 × 14 mesh, 132 × 17 mesh, 152 × 24 mesh, 152 × 30 mesh, 260 × 40 mesh, 250 × 40 mesh, 400 × 120 mesh.

Width: 100 mm to 1200 mm.

Length: 10 m to 30 m.

Other size available.

| Specifications of Stainless Steel Reverse Dutch Wire Mesh | ||

| Mesh (Weft × Warp) | Wire Diameter (mm) | Weight (kg/m2) |

| 72 × 15 | 0.45 × 0.55 | 4.8 |

| 120 × 16 | 0.35 × 0.45 | 4.3 |

| 132 × 18 | 0.35 × 0.45 | 4.3 |

| 152 × 24 | 0.35 × 0.45 | 4.5 |

| 160 × 17 | 0.27 × 0.45 | 3.6 |

| 170 × 17 | 0.27 × 0.45 | 3.89 |

| 180 × 19 | 0.26 × 0.45 | 4.05 |

| 200 × 40 | 0.17 × 0.27 | 2.17 |

| 260 × 40 | 0.15 × 0.25 | 2.09 |

| 325 × 40 | 0.13 × 0.24 | 1.95 |

![]()

Packing:

![]()

Questions: What specs are needed to quote?

Answer: Material, woven type, aperture or mesh counts, wire diameter, roll width x roll length and number of rolls.