-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

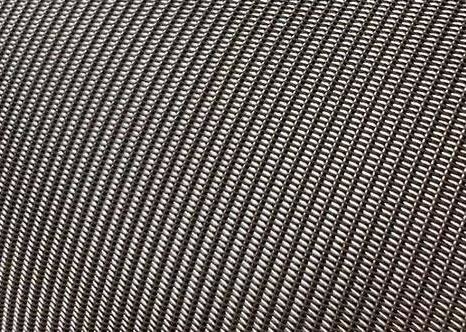

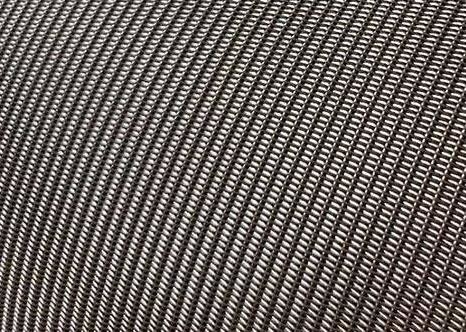

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

60 X 300 Mesh 40 Micron Plain Dutch Weave Mesh

| Features | Best Micronic Filter Media | Product Name | Stainless Steel Plain Dutch Weave Wire Mesh |

|---|---|---|---|

| Material | 304, 304L, 316, 316L, Other Metal Material Can Be Customized. | Standard | AISI, DIN |

| Aperture | 40μm | Weaving Type | Plain Dutch Weave |

| Mesh Counts | 60 X 300 | Roll Width | 1.0m,1.2m,1.5mm, Or Customed |

| Roll Length | 30m Or Cutsomed | Application | Filtering, Diffusing |

| Highlight | 60 x 300 mesh plain dutch weave mesh,40 micron plain dutch weave mesh |

||

60 X 300 Mesh 40 Micron Plain Dutch Weave Mesh Stainless Steel Dutch Wire Mesh

Plain Dutch Weave Wire Mesh

Plain Dutch weave cloth same as plain weaving square mesh, the difference is the diameter of the warp wire is larger than the weft wire.

The plain Dutch weave cloth is formed by weaving a limited number of warps wires with the maximum number of weft wires woven tightly together, producing a cloth with no readily visible aperture. the shape and position of the openings aid particle retention and increase filter cake formation.

Plain Dutch weave mesh is strong and stable, easy to clean and with a good flow rate suitable for high-pressure liquid/solid separation.

Specifications

| Mesh No.(warp/ | Wire dia.(mm) | Wire dia.(inch) | Fineness of | Weight | Weight |

| inch & weft/inch) | (warp & weft) | (warp & weft) | Filtering(micron) | (lb/square yard) | (kg/square meter) |

| 8/85 | 0.355/0.320 | 0.0140/0.01260 | 318-340 | 0.497 | 2.43 |

| 10/70 | 0.600/0.350 | 0.0240/0.01400 | 300-325 | 0.622 | 3.04 |

| 12/64 | 0.580/0.400 | 0.0230/0.01650 | 295-305 | 0.744 | 3.64 |

| 14/88 | 0.500/0.330 | 0.0190/0.01200 | 195-205 | 0.644 | 3.15 |

| 20/150 | 0.248/0.177 | 0.0098/0.00700 | 155-165 | 0.303 | 1.48 |

| 24/110 | 0.355/0.250 | 0.0150/0.01000 | 145-155 | 0.552 | 2.7 |

| 24/120 | 0.330/0.230 | 0.0130/0.00900 | 115-125 | 0.458 | 2.24 |

| 30/150 | 0.230/0.180 | 0.0090/0.00700 | 95-105 | 0.327 | 1.6 |

| 40/200 | 0.180/0.140 | 0.0070/0.00550 | 75-85 | 0.266 | 1.3 |

| 50/250 | 0.140/0.114 | 0.0055/0.00450 | 55-65 | 0.204 | 1 |

| 60/300 | 0.140/0.090 | 0.0055/0.00350 | 36-40 | 0.157 | 0.77 |

| 70/400 | 0.120/0.065 | 0.0047/0.00256 | 36-40 | 0.138 | 0.67 |

| 80/300 | 0.125/0.090 | 0.0049/0.00350 | 38-42 | 0.2 | 0.98 |

| 80/400 | 0.125/0.071 | 0.0049/0.00280 | 38-42 | 0.166 | 0.81 |

Other size according to your requirements.

Weave Type:

Plain Dutch Weave

Features:

Dutch Weave Metal wire mesh have the many advantages than square opening wire mesh, it is a best micronic filter media.

Allowing reasonable flow rates while insuring excellent particle size retention.

Flexible with excellent filtration performance

High hardness, good load strength, suitable for high-pressure liquid/solid separation.

High temperature resistance

Corrosion and rust resistance.

Zero aperture, Light-proof woven.

High resistance due to tight wire position.

Extreme low absolute grade of fineness (down to 2– 3 μm).

Acid and alkali resistance.

Applications:

Widely used as Extruder screens also named extruder screen mesh, that o be used at plastic or rubber processing machine to keep mixing of foreign particles away from

Finest filtration in hydraulic systems, especially for critical applications, such as aero-space and fuel. E extrusion product.

High tensile Warp wire for Auto-Screen changers used in the Plastic Extrusion Industry.

Best micronic filter media for pharmacy, food, medicine, chemical and other industries.

![]()

Packing:

Stainless steel wire mesh is packed in rolls,winding on a paper tube,wrapped in moisture-proof paper or plastic film, outside wooden cases or wooden pallet.

![]()

Questions: What specs are needed to quote?

Answer: Material, woven type, aperture or mesh counts, wire diameter, roll width x roll length and number of rolls.

| Weave of Type | Mesh/Inch | Wire Diameter | Nominal Micron |

|---|---|---|---|

| mm | μm | ||

| TRD | 48 ×10 | 0.50 × 0.50 | 400 |

| TRD | 72 × 15 | 0.50 × 0.50 | 300 |

| TRD | 132 ×14 | 0.35 × 0.45 | 200 |

| TRD | 132 × 18 | 0.35 × 0.44 | 180 |

| TRD | 152 × 24 | 0.27 × 0.40 | 160 |

| TRD | 152 × 30 | 0.27 × 0.30 | 130 |

| RPD | 250 ×40 | 0.15 × 0.25 | 90 |

| RPD | 260 × 40 | 0.15 × 0.27 | 125 |

| RPD | 280 × 70 | 0.089 × 0.21 | 45 |

| RPD | 325 × 39 | 0.13 × 0.24 | 55 |

| RPD | 600 ×125 | 0.043 × 0.12 | 20 |

| RPD | 720 × 150 | 0.035 × 0.107 | 15 |