-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

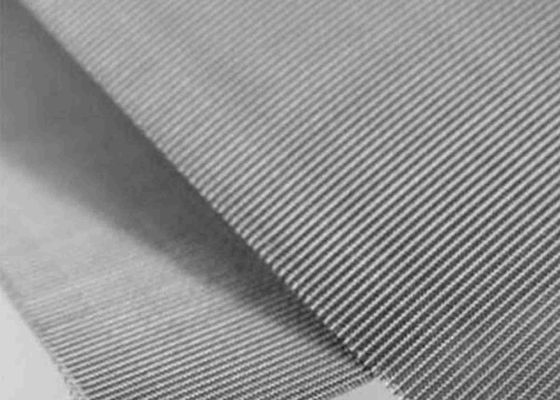

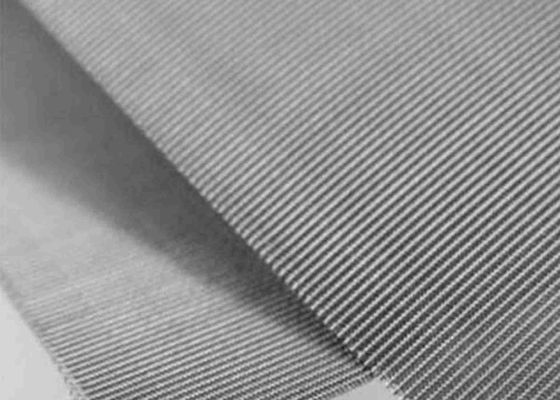

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

0.2m to 1.6m Wire Mesh Stainless Steel 316 Filtration Industry

| Features | Excellent Filtration Performance | Product Name | Stainless Steel Dutch Wire Mesh |

|---|---|---|---|

| Material | Stainless Steel | Standard | AISI, DIN |

| Surface | Bright Silver | Weaving Type | Plain Dutch Weave |

| Aperture Size | 23um To 347um | Roll Width | 0.2m To 1.6m |

| Roll Length | 10m, 20m, 30m, Etc | Application | Filtration Industry |

| Highlight | DIN 1.6m Wire Mesh Stainless Steel 316,DIN 0.2m Wire Mesh Stainless Steel 316,ss316 stainless mesh screen |

||

AISI and DIN Standard Plain Dutch Weave Stainless Steel Dutch Wire Mesh

Stainless Steel Plain Dutch Weave Wire Mesh Introduction:

Dutch weave wire mesh also known as “Hollander weave mesh” is ideal for high-pressure filtration as this is stronger and more durable than plain weave wire meshes. For the plain dutch weave, the shute wire is woven closely to the previous wire in plain weave manner (1/1). This simple dutch weave is the most common filter cloth. By varying diameter and tightness of the wire, special filtration effects and micron ratings can be achieved.

Plain Dutch Weaves can handle high flow rates with relatively low pressure drop. They are woven with each warp and shute wire passing over-and-underone wire. The shute wires, however, are smaller indiameter than the warp wires and are driven closetogether to create a dense weave. This weave producesa strong filter cloth with good flow rates which makes it useable for high pressure filtration. This type of mesh is usually used for liquid filtration for petrochemical, aerospace, pharmaceutical and even on wastewater treatment facilities.

Characteristics:

Warp wire has bigger dia than shute wire;

Shute wires are possibly bound close to each other;

High precision and flow rate;

High accuracy;

Nominal or no pressure loss while filtration;

Supreme filtration surface;

More stable than square and rectangular wire mesh;

It will filter more solid particle in comparison with square hole and rectangular hole;

Every weft wire tight with each other;

Features:

Excellent filtration performance;

Acid resistance;

High temperature resistance;

Tensil and abrasion resistence;

Stability of filtration;

Fine and high precision;

Material: Stainless Steel 304, 304L, 316, 316L, etc.

Weaving methods: Plain Dutch Weave ("Warp × Weft" same meaning to "Warp × Shute")

Specifications

Roll Width: 0.2m-1.6m

Roll Length: 10m, 20m, 30m; 100ft

|

Mesh Counts warp×weft (Mesh/Inch) |

Wire Diameter warp×weft (mm) |

Aperture Size (μm) |

Weight (kg/㎡) |

Thickness (mm) |

| 7×40 | 0.9×0.71 | 347 | 6.65 | 2.32 |

| 7×44 | 0.71×0.63 | 319 | 5.55 | 1.97 |

| 8×45 | 0.8×0.6 | 310 | 5.7 | 2.00 |

| 8.5×60 | 0.63×0.45 | 296 | 4.16 | 1.53 |

| 8×85 | 0.45×0.315 | 275 | 2.73 | 1.08 |

| 10×90 | 0.45×0.28 | 249 | 2.57 | 1.01 |

| 10×76 | 0.5×0.355 | 248 | 3.24 | 1.21 |

| 12×86 | 0.45×0.315 | 211 | 2.93 | 1.08 |

| 12×64 | 0.56×0.4 | 3.89 | 1.36 | |

| 12.5×76 | 0.45×0.355 | 192 | 3.26 | 1.16 |

| 14×100 | 0.40×0.28 | 182 | 2.62 | 0.96 |

| 14×110 | 0.355×.0.25 | 177 | 2.28 | 0.855 |

| 14×76 | 0.45×.0.355 | 173 | 3.33 | 1.16 |

| 16×100 | 0.4×0.28 | 160 | 2.7 | 0.96 |

| 17×120 | 0.355×0.224 | 155 | 2.19 | 0.803 |

| 16×120 | 0.28×0.224 | 145 | 1.97 | 0.728 |

| 20×140 | 0.315×0.20 | 133 | 0.715 | |

| 20×170 | 0.25×0.16 | 130 | 1.56 | 0.57 |

| 20×110 | 0.355×0.25 | 126 | 2.47 | 0.855 |

| 22×120 | 0.315×0.224 | 115 | 2.20 | 0.763 |

| 25×140 | 0.28×0.2 | 100 | 1.96 | 0.68 |

| 24×110 | 0.355×0.25 | 97 | 2.60 | 0.855 |

| 28×150 | 0.28×0.18 | 92 | 1.87 | 0.64 |

| 30×150 | 0.25×0.18 | 82 | 1.79 | 0.61 |

| 30×140 | 0.315×0.20 | 77 | 2.21 | 0.715 |

| 35×190 | 0.224×0.14 | 74 | 1.47 | 0.504 |

| 35×170 | 0.224×0.16 | 69 | 1.62 | 0.544 |

| 40×200 | 0.18×0.135 | 63 | 1.24 | 0.43 |

| 45×250 | 0.16×0.11 | 56 | 1.11 | 0.384 |

| 50×300 | 0.16×0.09 | 55 | 0.98 | 0.34 |

| 60×500 | 0.14×0.055 | 51 | 0.70 | 0.252 |

| 50×270 | 0.14×0.10 | 50 | 0.98 | 0.34 |

| 70×930 | 0.10×0.03 | 30 | 0.39 | 0.16 |

| 65×390 | 0.125×0.071 | 42 | 0.78 | 0.267 |

| 60×300 | 0.14×0.09 | 41 | 0.96 | 0.32 |

| 80×700 | 0.125×0.04 | 40 | 0.60 | 0.205 |

| 60×270 | 0.14×0.1 | 39 | 1.03 | 0.34 |

| 77×560 | 0.14×0.05 | 38 | 0.74 | 0.24 |

| 80×600 | 0.1×0.045 | 37 | 0.53 | 0.19 |

| 70×390 | 0.112×0.071 | 0.74 | 0.254 | |

| 65×750 | 0.10×0.036 | 36 | 0.43 | 0.172 |

| 70×340 | 0.125×0.08 | 35 | 0.86 | 0.285 |

| 80×430 | 0.125×0.063 | 32 | 0.77 | 0.251 |

| 100×1200 | 0.063×0.023 | 23 | 0.27 | 0.109 |

| 118×750 | 0.063×0.036 | 0.38 | 0.135 |

![]()

Application:

Pressure filters for fine filtration in hydraulic steering equipment.

Aerospace industry for composite material.

Oil and fuel filters.

Pressure and vacuum filters.

As porous media for fluid beds.

Filter candles.

Medical science.

Food and beverage industry.

Plastics industry.

![]()

Packing:

![]()

Questions: What specs are needed to quote?

![]()

Answer: Material, woven type, aperture or mesh counts, wire diameter, roll width x roll length and number of rolls.