-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

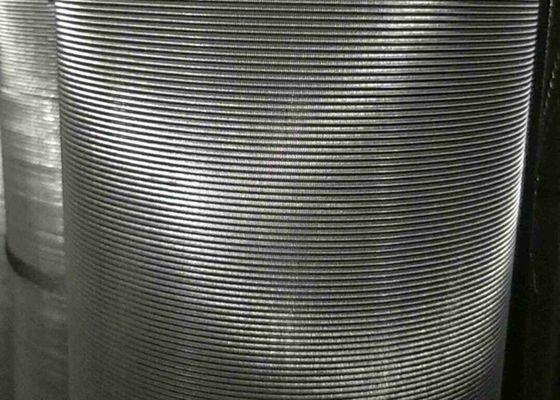

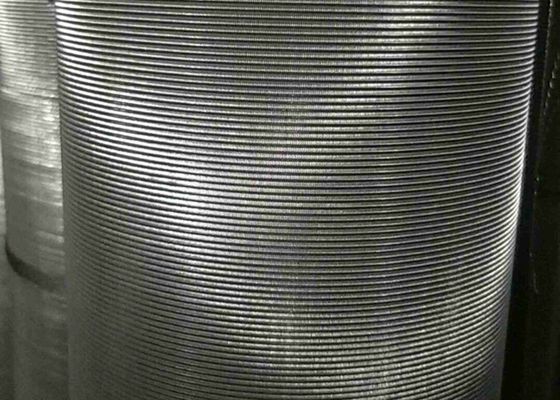

Plastic Extruder Stainless Steel Dutch Wire Mesh 130×32 Dutch Weave

| Place of Origin | Anping of China |

|---|---|

| Brand Name | QIANPU |

| Certification | ISO |

| Minimum Order Quantity | 1 roll |

| Price | Negotiable according to quantity of order |

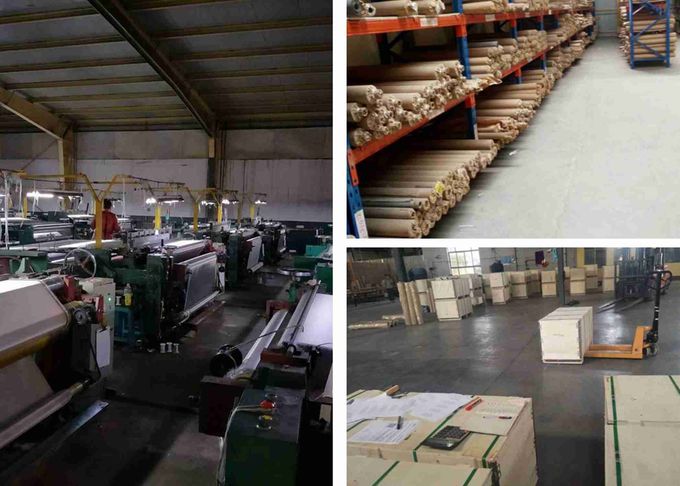

| Packaging Details | 1. inside use carton pipe for support+wire mesh layer+water proof paper 2. outside use plastic wooden bags+wooden case/carton pipes/wooden pallets. 3. also we can as per your requirements. |

| Delivery Time | 2 weeks |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 3000 rolls per month |

| Features | Fine Mesh Holes Give Very High Filter Precision | Product Name | Plastic Extruder Dutch Weave Wire Mesh |

|---|---|---|---|

| Material | Stainless Steel 304 | Application | Filtration, Sieve |

| Width | 1.2m,1.5m Or Customized | Length | 30m Or Customized |

| Technique | Dutch Weave | Color | Silver |

| Mesh Size | 14/88 | Useage | Can Be Made To Extruder Screens For Melt Filtration. |

| Highlight | 32 Stainless Steel Dutch Wire Mesh,130 Stainless Steel Dutch Wire Mesh,Dutch Weave stainless wire cloth |

||

Plastic Extruder Dutch Weave 130×32 Stainless Steel Dutch Wire Mesh

Plain Dutch Weave or Twill Dutch Weave Woven Wire Cloth Introduction

We fabric woven wire cloth from stainless steel wire with plain dutch weave or twill dutch weave for melt filtration.

Plain dutch weave: The pattern of this mesh is the same as in plain weave except that the warp wires are of a larger diameter than the shute wires and the shute wires are driven up close to each other, resulting in tapers or wedge-shaped opening instead of square opening. In dutch weave the warp wires remain in straight conditions and the shute wires are crimped.

Twilled dutch weave: Wire cloth which has the same pattern as twilled weave except the warp wires are of a larger diameter than the shute wires & the shute wires are driven up tapers or wedge-shaped opening. Warp wires remain in a straight condition, but the shute wires take all the crimp. Due to the twilled weave construction, the shute wires are not only deformed in depth (crimps when formed around the warp wires) but also sideways.

| Warp/Shute Mesh | Gauge | Wire Diameter (mm) | Nominal Micron Retention |

|---|---|---|---|

| 12/64 | 26 × 26 | 0.457 × 0.457 | 180 |

| 24/110 | 28 × 32 | 0.376 × 0.274 | 115 |

| 30/250 | 38 × 42 | 0.132 × 0.102 | 70 |

| 50/250 | 38.5 × 41 | 0.140 × 0.112 | 60 |

| 50/600 | 40 × 44 | 0.122 × 0.081 | 30 |

| 80/400 | 40 × 45.5 | 0.102 × 0.063 | 40 |

| 80/700 | 42 × 44 | 0.102 × 0.063 | 35 |

| 100/600 | 42 × 45.5 | 0.102 × 0.081 | 25 |

| 120/600 | 42 × 45.5 | 0.102 × 0.063 | 28 |

| 170/1400 | 43.5 × 48 | 0.063 × 0.040 | 10 |

| 200/600 | 47 × 48 | 0.50 × 0.040 | 20 |

| 325/2300 | 48 × 40 | 0.40 × 0.122 | 5 |

Features:

1 Fine mesh holes give very high filter precision.

2 High tensile strength and can operate under heavy pressure.

3 Has a solid structure and a long service life.

Applications:

woven wire cloth is mainly used in the absorption, evaporation and filtration process in petroleum, chemical, medicine, metallurgy, machinery, ship and automobiles to delete the mist drop or liquid foam or used as air filter in cars and trucks. And can be made to extruder screens for melt filtration.

Dutch weave extruder disc has very fine mesh holes.

Dutch weave extruder screen can be ring shape.

Dutch weave extruder screen can be designed into kidney or other custom shapes.

Dutch weave extruder screen belt for continuous screen changers.

![]()

Packing:

Questions: What specs are needed to quote?

Answer: Material, woven type, aperture or mesh counts, wire diameter, roll width x roll length and number of rolls.