-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

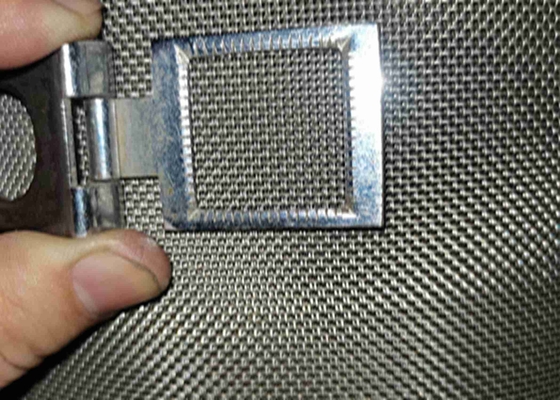

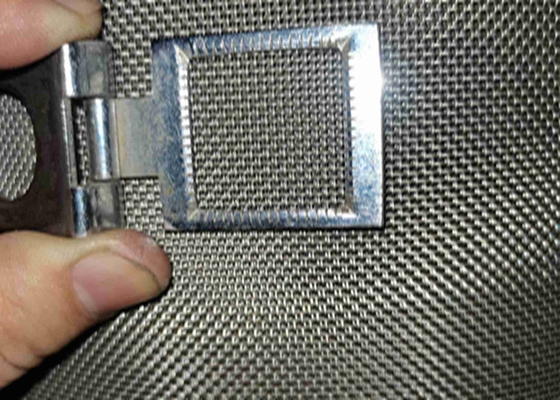

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Robust Fecral Wire Mesh Against Oxidation Sulfur Resistance For Industrial Use

| Features | Heat Resistance, Maintains Structural Integrity Even At Elevated Temperatures | Product Name | FeCrAl Woven Wire Mesh |

|---|---|---|---|

| Material | 1Cr13Al4, 1Cr12Al4, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2. | Hole Shapes | Square |

| Woven Type | Plain Weave And Twill Weave. | Mesh Counts | 8 Mesh - 80 Mesh. |

| Wire | 0.05 To 0.28mm | Usage | Used As Heaters And Dryers |

| Highlight | Robust Fecral Wire Mesh,Industrial Fecral Wire Mesh,Fecral Metal Woven Wire Mesh |

||

FeCrAl Wire Mesh Robust Against Oxidation Sulfur Resistance

FeCrAl Woven Wire Mesh Introduction:

FeCrAl, an iron-chromium-aluminum alloy, is known for its excellent heat resistance. This wire mesh is commonly used in industrial heating elements, high-temperature furnaces, and in applications requiring durability at high temperatures.

We are committed to delivering FeCrAl wire mesh that adheres to the highest quality and efficiency standards. Our mesh, crafted from premium raw materials, is woven into a continuous and durable form. Our diverse range includes iron-chromium-aluminum woven mesh, steel mesh, and perforated mesh, catering to a variety of industrial needs. Known for its remarkable heat and oxidation resistance, our FeCrAl wire mesh is also recognized for its versatility and is often referred to as FeCrAl alloy wire mesh, heat-resistant alloy braided wire, and electrothermal alloy mesh.

Product Also Known As

FeCrAl Wire Mesh:

Offers exceptional durability and heat resistance, making it ideal for high-temperature industrial applications, such as in furnaces and drying equipment.

FeCrAl Alloy Woven Wire Mesh:

Combines strength and flexibility, resisting both oxidation and sulfur, suitable for harsh chemical environments in industrial processing.

Heating Resistance Alloy Woven Wire:

Designed to withstand extreme temperatures, this wire mesh is perfect for use in metallurgical and food processing industries.

Electrothermal Alloy Mesh:

Ideal for electrical heating applications, offering high resistivity and efficiency in appliances and industrial heating systems.

Features:

High-Temperature Resilience: FeCrAl wire mesh, recognized for its heat resistance, maintains structural integrity even at elevated temperatures.

Robust Against Oxidation: Its composition renders it resistant to oxidation, enhancing its longevity in various settings.

Sulfur Resistance: The mesh stands strong against sulfur exposure, making it suitable for harsh environments.

Impenetrability: Designed to prevent penetration, it ensures enhanced safety and application integrity.

Applications:

Diverse Industrial Heating Uses: FeCrAl wire mesh is crucial in heating and drying equipment across sectors like metallurgy, mining, dyeing, food processing, and healthcare.

Manufacturing and Processing: It’s extensively used in the production of high-density boards, highlighting its industrial adaptability.

Electric Furnaces: This mesh is a key component in industrial electric furnaces due to its heat-resistant properties.

Domestic and Commercial Appliances: Its application extends to household appliances, gas burners, and infrared devices, showcasing its utility in both home and commercial environments.

Materials:

| Table 1: Chemical Compositions of L605 Wire Cloth (%) | ||||||||

| Element | C | Co | Cr | Fe | Mn | Ni | Si | W |

| Content | 0.05–0.15 | Rem. | 19–21 | 3 | 1.0–2.0 | 9.0–11.0 | 0.4 | 14.0–16.0 |

Specifications

Material: 1Cr13Al4, 1Cr12Al4, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2.

Mesh size: 8 mesh - 80 mesh.

Wire diameter: 21G - 43G.

Weaving type: plain weave and twill weave.

Max working temperature:

1Cr13Al4 - 950 degree.

1Cr21Al4 - 1100 degree.

0Cr21Al6 - 1250 degree.

0Cr23Al5 - 1250 degree.

0Cr25Al5 - 1250 degree.

0Cr21Al6Nb - 1350 degree.

0Cr27Al7Mo2 - 1400 degree.

| Mesh | Wire Gauge | Aperture (mm) | Wire Diameter (mm) | Roll Width (m) | Weight (kg/m2) |

| 8 (T) | 21 | 2.375 | 0.8 | 1 | 2.5 |

| 8 (T) | 22 | 2.475 | 0.7 | 1 | 1.84 |

| 10 (T) | 23 | 1.94 | 0.6 | 0.6 | 1.69 |

| 12 (T) | 24 | 1.557 | 0.559 | 1 | 1.8 |

| 17 (T) | 24 | 0.94 | 0.55 | 0.6 | 2.57 |

| 20 (P) | 33 | 1.02 | 0.25 | 1 | 0.587 |

| 20 (P) | 32 | 1 | 0.27 | 1 | 0.685 |

| 20 (P) | 30 | 0.97 | 0.3 | 1 | 0.846 |

| 25 (P) | 30 | 0.71 | 0.3 | 1 | 1.125 |

| 30 (P) | 38 | 0.69 | 0.15 | 1 | 0.3 |

| 34 (P) | 33 | 0.49 | 0.25 | 1 | 1.06 |

| 40 (P) | 35 | 0.425 | 0.21 | 1 | 0.83 |

| 40 (T) | 35 | 0.425 | 0.21 | 1 | 0.83 |

| 44 (T) | 35 | 0.367 | 0.21 | 1 | 0.88 |

| 60 (T) | 38 | 0.273 | 0.15 | 1 | 0.66 |

| 80 (P) | 43 | 0.227 | 0.09 | 1 | 0.324 |

Other specifications according to your request.

Packing:

![]()