All Products

-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

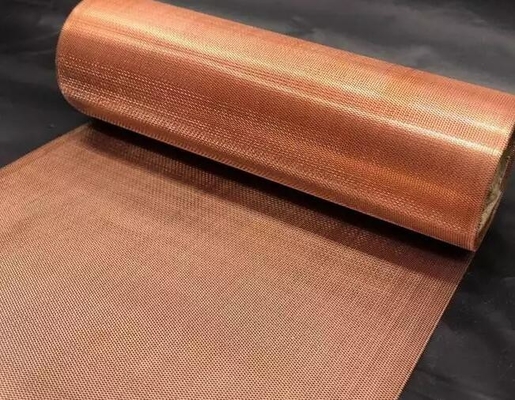

Copper Woven Wire Mesh With Slit Edge With Resists Atmospheric And Moisture Corrosion

Product Details

| Product Name | Copper Wire Mesh | Material | Copper |

|---|---|---|---|

| Standard | ASTM | Hole Shape | Square |

| Woven Edges | Cut Edges | Mesh Counts | 6 To 20 Per Inch |

| Weaving Type | Plain Dutch, Twill Dutch | Width | Up To 3.0m |

| Properties | Stability And Ety Handling | Usages | EMI Shielding In Electronic Devices. |

| Highlight | Slit Edge Woven Wire Mesh,Atmospheric Woven Wire Mesh,Moisture Corrosion Woven Wire Mesh |

||

Product Description

Copper Woven Wire Mesh With Slit Edge With Resists Atmospheric And Moisture Corrosio

1. Copper wire mesh Introduction:

Copper woven wire mesh is crafted from pure copper wires (99.9% Cu) or high-copper alloys. The wires are woven into grids using techniques like plain, twill, or Dutch weaves. The process involves drawing copper into thin wires, followed by annealing (heat treatment) to enhance flexibility for intricate weaving. Unlike brass or aluminum, copper’s natural softness requires careful handling during fabrication.

2. Key Properties:

High Conductivity: Exceptional electrical and thermal conductivity, superior to most metals.

Corrosion Resistance: Resists atmospheric and moisture corrosion; forms a protective green patina over time.

Antimicrobial: Naturally inhibits bacterial growth, ideal for sanitary environments.

Malleability/Ductility: Easily shaped without cracking, suitable for complex designs.

Non-Sparking: Safe for flammable or explosive environments.

Aesthetic Appeal: Distinctive reddish-gold color, often used decoratively.

Weight: Heavier than aluminum but lighter than steel.

3. Applications:

Electrical/Electronics: EMI/RFI shielding, grounding meshes, and circuit board components.

Decorative: Architectural facades, light fixtures, and artistic installations.

Filtration/Sieving: Fine filtration in laboratories, food processing, and pharmaceutical industries.

HVAC Systems: Corrosion-resistant air vents and anti-microbial screens.

Medical: Antimicrobial screens for hospitals and cleanrooms.

Marine: Components for boats and coastal structures due to saltwater resistance.

Agriculture: Pest barriers and plant supports.

Roofing: Lightning protection and architectural detailing.

4. Types and Variations:

Weave Patterns: Plain weave (standard), twill (dense), Dutch weave (ultra-fine filtration).

Mesh Specifications: Wire diameter (0.03–2.0 mm), mesh count (1–200 openings per inch).

Surface Treatments: Lacquered, tin-plated, or coated to prevent tarnishing.

Alloys: Rarely alloyed but may include trace elements for enhanced strength.

5. Advantages:

Unmatched electrical/thermal conductivity.

Antimicrobial and corrosion-resistant.

Aesthetic versatility and non-sparking safety.

Fully recyclable and eco-friendly.

6. Standards and Specifications:

Governed by ASTM B152 (copper sheetrip standards) and ISO 9044 (woven wire mesh).

Key parameters: Purity (C10100, C11000), mesh count, wire diameter, and tensile strength.

7. Purchasing Considerations:

Specify mesh count, wire gauge, and sheet/roll dimensions.

Choose surface treatments (e.g., tin plating for solderability, lacquer for tarnish resistance).

Opt for higher purity grades (C10100) for electrical applications.

8. Safety and Handling:

Wear gloves to avoid cuts from sharp edges.

Use non-abrasive tools to cut (e.g., tin snips) to minimize burrs.

Grounding essential in electrical applications to prevent shocks.

9. Environmental Impact:

100% recyclable without loss of properties; high scrap value.

Mining impacts are offset by long lifecycle and efficient recycling.

10. Common Confusions:

Copper vs. Brass/Bronze: Brass (Cu+Zn) and bronze (Cu+Sn) are alloys; copper mesh is pure or near-pure.

Woven vs. Expanded Metal: Expanded metal is slitretched, not woven.

11. Examples of Use:

EMI shielding in electronic devices.

Decorative room dividers in luxury interiors.

Laboratory sieves for particle analysis.

Antimicrobial screens in hospital ventilation systems.

Sculptural elements in public art installations.

Conclusion:

Copper woven wire mesh is unparalleled in applications demanding conductivity, corrosion resistance, and antimicrobial properties. While softer and costlier than steel or aluminum, its unique benefits make it indispensable in electronics, medical, marine, and decorative sectors. Proper selection of weave, mesh size, and surface treatment ensures optimal performance and longevity.

Specifications

| Brass Woven Wire Mesh | |||

| Mesh Count |

Wire Diameter (mm) |

Aperture Size (mm) |

Open Area Rate (%) |

| 6 | 0.40 | 3.833 | 81.99 |

| 0.50 | 3.733 | 77.77 | |

| 0.60 | 3.633 | 73.66 | |

| 0.70 | 3.533 | 69.66 | |

| 8 | 0.40 | 2.775 | 76.39 |

| 0.50 | 2.675 | 70.98 | |

| 10 | 0.35 | 2.190 | 74.30 |

| 0.40 | 2.140 | 70.98 | |

| 0.50 | 2.040 | 64.50 | |

| 12 | 0.35 | 1.770 | 69.66 |

| 0.40 | 1.716 | 65.77 | |

| 0.50 | 1.616 | 58.33 | |

| 14 | 0.30 | 1.514 | 69.66 |

| 0.35 | 1.464 | 65.13 | |

| 0.40 | 1.414 | 60.76 | |

| 0.50 | 1.314 | 52.47 | |

| 16 | 0.25 | 1.337 | 70.98 |

| 0.27 | 1.317 | 68.87 | |

| 0.40 | 1.187 | 55.95 | |

| 18 | 0.15 | 1.261 | 79.87 |

| 0.17 | 1.241 | 77.35 | |

| 0.19 | 1.221 | 74.88 | |

| 0.21 | 1.201 | 72.45 | |

| 0.25 | 1.161 | 67.7 | |

| 0.30 | 1.111 | 62.00 | |

| 0.40 | 1.011 | 51.34 | |

| 20 | 0.19 | 1.080 | 72.31 |

| 0.21 | 1.060 | 69.66 | |

| 0.25 | 1.020 | 64.50 | |

| 0.30 | 1.970 | 58.33 | |

| 0.40 | 0.870 | 46.92 | |

Other specifications according to your requirements.

![]()

Brass wire mesh is packed in rolls,winding on a paper tube,wrapped in moisture-proof paper or plastic film, outside wooden cases or wooden pallet.

![]()

Recommended Products