-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

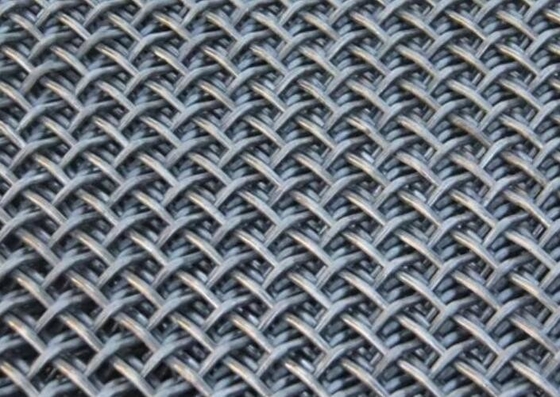

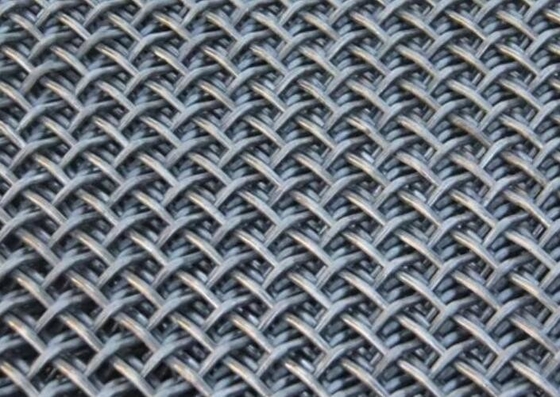

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Plain Crimped Wire Mesh Stainless Steel And Carbon Steel Material 1mm To 100mm Opening

| Place of Origin | Anping of China |

|---|---|

| Brand Name | QIANPU |

| Certification | ISO |

| Minimum Order Quantity | 10roll |

| Price | Negotiable |

| Packaging Details | Inside with a paper tube, outside with plastic film or waterproof paper, then in wooden cases or pallets. |

| Delivery Time | 2 weeks |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 2300 Meter/Meters per Month |

| Features | The Diameter And Mesh With Ratio Reasonable, Flat Surface, Strong Wear Resistance And Firm Structure | Product Name | Plain Crimped Wire Mesh |

|---|---|---|---|

| Material | Stainless Steel Wire, Carbon Steel Material, Etc | Type | Plain Crimped Weave |

| Hole Sapes | Square, Rectangular | Technique | Weaving After Crimping |

| Mesh Counts | 1 To 100mm | Width | 1 To 4m |

| Length | 30m Or Customized | Application | Machine Guards, Vibrating Screens, Architecture, Decorative Grill, Ety Screen, Etc |

| Highlight | 100mm Opening Crimped Wire Mesh,Plain Stainless Steel Crimped Wire Mesh,1mm Opening Crimped Wire Mesh |

||

Plain Crimped Type Bright Silver Stainless Steel Crimped Wire Mesh

Plain Crimped Wire Mesh Introduction

Standard type of weave for wire cloth resulting in square openings with wire sizes the same in both directions. Each warp wire passes alternately over and under fill wires at right angles both directions.

Specifications:

Opening Sizes: from 5mm to 100mm.

Wire Diameters: from 0.5mm to 8.0mm.

Roll Width: 1m, 1.22m, 1.5m to 4m.

Roll Length: 15m, 30m to 60m.

Panel Width: 0.5m, 0.914m, 1m, 1.22m to 2m.

Panel Length: 1m, 1.22m, 1.5m to 6m.

| Opening L | Wire D | Open Area | ||

| mm | inch | mm | inch | % |

| 1 | 0.039 | 0.6 | 0.024 | 39.06 |

| 0.039 | 0.5 | 0.02 | 44.44 | |

| 2 | 0.079 | 1 | 0.039 | 44.44 |

| 0.079 | 0.9 | 0.035 | 47.56 | |

| 0.079 | 0.8 | 0.031 | 51.02 | |

| 0.079 | 0.6 | 0.024 | 59.17 | |

| 0.079 | 0.5 | 0.02 | 64 | |

| 4 | 0.157 | 2.3 | 0.091 | 40.31 |

| 0.157 | 2 | 0.079 | 44.44 | |

| 0.157 | 1.8 | 0.071 | 47.56 | |

| 0.157 | 1.6 | 0.063 | 51.02 | |

| 0.157 | 1.4 | 0.055 | 54.87 | |

| 0.157 | 1.2 | 0.047 | 59.17 | |

| 5 | 0.197 | 3.2 | 0.126 | 37.18 |

| 5 | 0.197 | 2.9 | 0.114 | 40.06 |

| 0.197 | 2.6 | 0.102 | 43.28 | |

| 0.197 | 2.3 | 0.091 | 46.91 | |

| 0.197 | 2 | 0.079 | 51.02 | |

| 0.197 | 1.8 | 0.071 | 54.07 | |

| 0.197 | 1.6 | 0.063 | 57.39 | |

| 0.197 | 1.4 | 0.055 | 61.04 | |

| 0.197 | 1.2 | 0.047 | 65.04 | |

| 6 | 0.236 | 4 | 0.157 | 36 |

| 0.236 | 3.6 | 0.142 | 39.06 | |

| 0.236 | 3.2 | 0.126 | 42.53 | |

| 0.236 | 2.9 | 0.114 | 45.45 | |

| 0.236 | 2.6 | 0.102 | 48.67 | |

| 0.236 | 2.3 | 0.091 | 52.26 | |

| 0.236 | 2 | 0.079 | 56.25 | |

| 0.236 | 1.8 | 0.071 | 59.17 | |

| 0.236 | 1.6 | 0.063 | 62.33 | |

| 8 | 0.315 | 4 | 0.157 | 44.44 |

| 0.315 | 3.6 | 0.142 | 47.56 | |

| 0.315 | 3.2 | 0.126 | 51.02 | |

| 0.315 | 2.9 | 0.114 | 53.87 | |

| 0.315 | 2.6 | 0.102 | 56.96 | |

| 0.315 | 2.3 | 0.091 | 60.33 | |

| 0.315 | 2 | 0.079 | 64 | |

| 10 | 0.394 | 4.8 | 0.189 | 45.65 |

| 0.394 | 4.4 | 0.173 | 48.23 | |

| 0.394 | 4 | 0.157 | 51.02 | |

| 10 | 0.394 | 3.6 | 0.142 | 54.07 |

| 0.394 | 3.2 | 0.126 | 57.39 | |

| 0.394 | 2.9 | 0.114 | 60.09 | |

| 0.394 | 2.6 | 0.102 | 62.99 | |

| 0.394 | 2.3 | 0.091 | 66.1 | |

| 12.7 | 0.5 | 6.4 | 0.252 | 44.21 |

| 0.5 | 5.8 | 0.228 | 47.13 | |

| 0.5 | 5.3 | 0.209 | 49.78 | |

| 0.5 | 4.8 | 0.189 | 52.67 | |

| 0.5 | 4.4 | 0.173 | 55.16 | |

| 0.5 | 4 | 0.157 | 57.83 | |

| 0.5 | 3.6 | 0.142 | 60.71 | |

| 0.5 | 3.2 | 0.126 | 63.8 | |

| 0.5 | 2.9 | 0.114 | 66.28 | |

| 20 | 0.787 | 7 | 0.276 | 54.87 |

| 0.787 | 6.4 | 0.252 | 57.39 | |

| 0.787 | 5.8 | 0.228 | 60.09 | |

| 0.787 | 5.3 | 0.209 | 62.49 | |

| 0.787 | 4.8 | 0.189 | 65.04 | |

| 0.787 | 4.4 | 0.173 | 67.19 | |

| 0.787 | 4 | 0.157 | 69.44 | |

| 25.4 | 1 | 9.5 | 0.374 | 52.97 |

| 1 | 8.8 | 0.346 | 55.16 | |

| 1 | 8.2 | 0.323 | 57.15 | |

| 1 | 7.6 | 0.299 | 59.24 | |

| 1 | 7 | 0.276 | 61.46 | |

| 1 | 6.4 | 0.252 | 63.8 | |

| 25.4 | 1 | 5.8 | 0.228 | 66.28 |

| 1 | 5.3 | 0.209 | 68.45 | |

| 1 | 4.8 | 0.189 | 70.74 | |

| 50.8 | 2 | 12.7 | 0.5 | 64 |

| 2 | 11.7 | 0.461 | 66.06 | |

| 2 | 11.1 | 0.437 | 67.35 | |

| 2 | 10.9 | 0.429 | 67.79 | |

| 2 | 10.1 | 0.398 | 69.58 | |

| 2 | 9.5 | 0.374 | 70.97 | |

| 63.5 | 2.5 | 12.7 | 0.5 | 69.44 |

| 2.5 | 11.7 | 0.461 | 71.3 | |

| 2.5 | 11.1 | 0.437 | 72.46 | |

| 2.5 | 10.9 | 0.429 | 72.85 | |

| 2.5 | 10.1 | 0.398 | 74.44 | |

| 2.5 | 9.5 | 0.374 | 75.67 | |

| 76.2 | 3 | 12.7 | 0.5 | 73.47 |

| 3 | 11.7 | 0.461 | 75.15 | |

| 3 | 11.1 | 0.437 | 76.19 | |

| 3 | 10.9 | 0.429 | 76.54 | |

| 3 | 10.1 | 0.398 | 77.96 | |

| 88.9 | 3 | 12.7 | 0.5 | 76.56 |

| 3.5 | 11.7 | 0.461 | 78.09 | |

| 3.5 | 11.1 | 0.437 | 79.03 | |

| 101.6 | 4 | 12.7 | 0.5 | 79.01 |

Other Specifications according to your requirements.

Material:

Standard materials of flat top crimped wire mesh are low/mild/high carbon steel and stainless steel 201, 202, 304, 316, 321, 410, 430.

Besides above following material available:

Copper: brass, pure copper, phosphor bronze

Aluminum: 1050, 1060, 1100, 5052, 5056

Nickel: pure nickel, nickel alloy, monel

Characteristics and usage:

Plain crimped wire mesh combines the characteristics of both plain weave and crimped wire mesh. In this type of wire mesh, the wires are crimped before weaving in a simple one-over-one-under pattern, creating a mesh with added strength and stability. Here are some key features and characteristics of plain crimped wire mesh:

Crimped Wires: The wires used in plain crimped wire mesh are pre-crimped before weaving, which adds rigidity and structural integrity to the mesh.

Plain Weave Pattern: The crimped wires are woven together in a basic plain weave pattern, where each weft wire passes over and under each warp wire in a consistent one-over-one-under configuration.

Strength and Stability: The combination of crimped wires and plain weave pattern results in a wire mesh with increased strength, stability, and resistance to deformation under pressure.

Uniform Mesh Opening: Plain crimped wire mesh offers a uniform mesh opening size throughout the mesh, providing consistent filtration and screening properties.

Versatility: Plain crimped wire mesh is versatile and can be used in various applications, including mining, construction, agriculture, filtration, and industrial processes requiring strong and durable mesh materials.

Good Filtration Efficiency: The sturdy construction of plain crimped wire mesh makes it suitable for applications where effective filtration and screening are essential.

Material Options: Plain crimped wire mesh can be manufactured using different materials such as stainless steel, galvanized steel, and other metals, allowing for customization based on specific application requirements.

Durability: The combination of crimped wires and plain weave pattern enhances the durability and longevity of plain crimped wire mesh, making it a reliable choice for demanding applications.

Overall, plain crimped wire mesh is a robust and versatile material that offers strength, stability, and consistent filtration properties, making it suitable for a wide range of industrial and commercial applications.

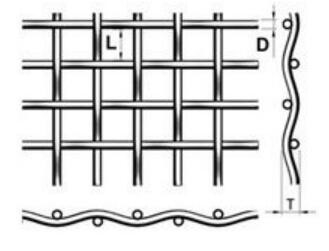

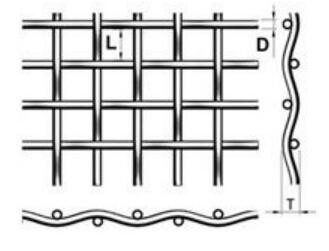

Plain Crimped Techniques:

![]()

![]()

Packing:

![]()