-

SS Welded Wire Mesh

-

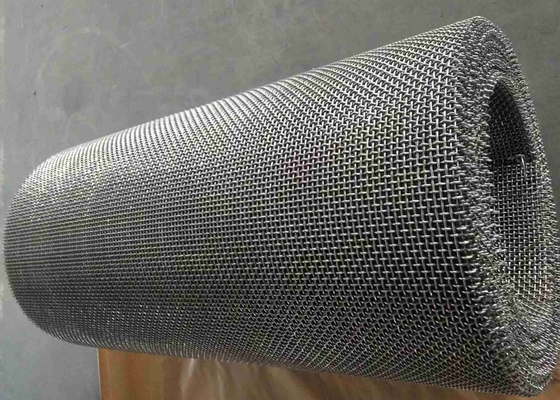

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Hastelloy Metal Woven Wire Mesh Hastelloy B Hastelloy C22 Hastelloy C276 And Hastelloy X

| Features | Outstanding Filtering Performance | Product Name | Hastelloy Woven Wire Mesh |

|---|---|---|---|

| Material | Hastelloy B, Hastelloy C22, Hastelloy C276 And Hastelloy X | Standard | ASTM |

| Hole Shapes | Square | Woven Type | Plain Weave, Twill Weave |

| Mesh Counts | 6 To 200 | Roll Length | 30m |

| Roll Width | 0.5m - 3.0m | Usages | Chlorination Devices |

| Highlight | hastelloy metal woven wire mesh,astm metal woven wire mesh,hastelloy b woven wire mesh |

||

Hastelloy Woven Wire Mesh Hastelloy B, Hastelloy C22, Hastelloy C276 And Hastelloy X

Hastelloy Woven Wire Mesh Introduction:

Hastelloy woven wire mesh is another nickel-based alloy woven wire mesh except for the monel woven wire mesh and nichrome woven wire mesh. The hastelloy is the alloy of nickel, molybdenum and chromium. According to the different chemical composition of material, the hastelloy can be divided into hastelloy B, Hastelloy C22, Hastelloy C276 and Hastelloy X.

Hastelloy woven wire mesh is the best corrosion resistant material among all of the metal materials. It is corrosion resistant in the acid, oxidizing, salt and other corrosion environments.

Hastelloy B standard woven wire mesh is the most widely used type in all types of hastelloy materials. It is resistant to hydrochloric acid at all concentrations, temperature and condition. That is, the hastelloy woven wire cloth can work well in high temperature even in the boiling point. It can also play a good performance in the hydrogen chloride gas. The Hastelloy B-3 is more excellent than the B-2, because it is less cracking and has higher chemical stability.

Materials:

| Chemical Composition of Material | ||||||||||||||

| Type | C | Co | Cr | Cu | Fe | Mn | Mo | Ni | P | S | Si | Sn | V | W |

| H-B | 0.12 | 2.5 | 1 | - | 6 | 1 | 26.0 - 30.0 | Rem. | 0.01 | - | 0.03 | - | 0.6 | - |

| H-C22 | 0.015 | 2.5 | 14.5 - 20.0 | - | 2.0 - 6.0 | 0.5 | 12.8 - 14.5 | Rem. | - | 0.02 | 0.08 | - | 0.35 | - |

| H-C276 | 0.02 | 2.5 | 14.5 - 16.5 | - | 4.0 - 7.0 | 1 | 15.0 - 17.0 | Rem. | 0.03 | 0.03 | 0.08 | - | 0.35 | 3.0 - 4.5 |

| H-X | 0.08 | - | 17.0 - 20.0 | 1 | Rem. | 2 | - | 34.0 - 37.0 | 0.03 | 0.03 | 0.75 - 1.50 | 0.025 | - | - |

Features:

Corrosion resistance.

Acid and alkali resistance.

High temperature resistance.

Salty resistance.

Chemical stability.

Outstanding filtering performance.

Application:

The hastelloy woven wire mesh has best corrosion resistance in acid, alkali, salty and other corrosive environments. It has various applications.

Drugs manufacturing.

Cellophane preparation.

Chlorination devices.

Pesticide processing.

Incineration scrubber apparatus.

Main Specs:

| Specification of Hastelloy B woven wire mesh | |||

| Mesh (Wires/ in.) | Wire diameter (in.) | Width of opening (in.) | Open area (%) |

| 16 × 16 | 0.014 | 0.049 | 60.2 |

| 30 × 30 | 0.0085 | 0.025 | 55.4 |

| 30 × 30 | 0.0106 | 0.0227 | 46.5 |

| 60 × 60 | 0.0072 | 0.009 | 30.5 |

| 200 × 200 | 0.002 | 0.003 | 36 |

| Specification of Hastelloy C276 woven wire mesh | |||

| Mesh (Wires/ in.) | Wire diameter (in.) | Width of opening (in.) | Open area (%) |

| 6 × 6 | 0.047 | 0.12 | 51.8 |

| 8 × 8 | 0.032 | 0.093 | 55.4 |

| 10 × 10 | 0.025 | 0.075 | 56.3 |

| 12 × 12 | 0.023 | 0.06 | 51.8 |

| 12 × 12 | 0.016 | 0.067 | 64.5 |

| 12 × 12 | 0.015 | 0.068 | 66.6 |

| 14 × 14 | 0.02 | 0.051 | 51 |

| 16 × 16 | 0.018 | 0.045 | 50.7 |

| 16 × 16 | 0.009 | 0.0535 | 73.27 |

| 20 × 20 | 0.023 | 0.027 | 29.2 |

| 20 × 20 | 0.016 | 0.034 | 46.2 |

| 20 × 20 | 0.009 | 0.041 | 67.2 |

| 24 × 24 | 0.014 | 0.028 | 44.2 |

| 30 × 30 | 0.013 | 0.02 | 37.1 |

| 30 × 30 | 0.009 | 0.024 | 53.1 |

| 40 × 40 | 0.01 | 0.015 | 36 |

| 40 × 40 | 0.009 | 0.016 | 41 |

| 40 × 40 | 0.0075 | 0.018 | 49 |

| 50 × 50 | 0.009 | 0.011 | 30.3 |

| 60 × 60 | 0.0072 | 0.009 | 30.5 |

| 60 × 60 | 0.0044 | 0.0123 | 54.2 |

| 80 × 80 | 0.007 | 0.006 | 19.4 |

| 80 × 80 | 0.001 | 0.0085 | 46.2 |

| 100 × 100 | 0.001 | 0.006 | 36 |

| 120 × 120 T | 0.004 | 0.0043 | 27 |

| 180 × 180 | 0.002 | 0.0036 | 41 |

| 200 × 200 | 0.0023 | 0.0027 | 48 |

| 200 × 200 | 0.002 | 0.003 | 36 |

| Specification of Hastelloy X woven wire mesh | |||

| Mesh (Wires/ in.) | Wire diameter (in.) | Width of opening (in.) | Open area (%) |

| 10 × 10 | 0.025 | 0.075 | 56.3 |

| 18 × 18 | 0.009 | 0.047 | 70.4 |

| 20 × 20 | 0.016 | 0.034 | 46.2 |

| 50 × 50 | 0.003 | 0.017 | 72.3 |

| 60 × 60 | 0.0075 | 0.009 | 30.5 |

![]()

Packing:

Inside with a paper core, outside with a piece of waterproof, the in wooden case.