-

SS Welded Wire Mesh

-

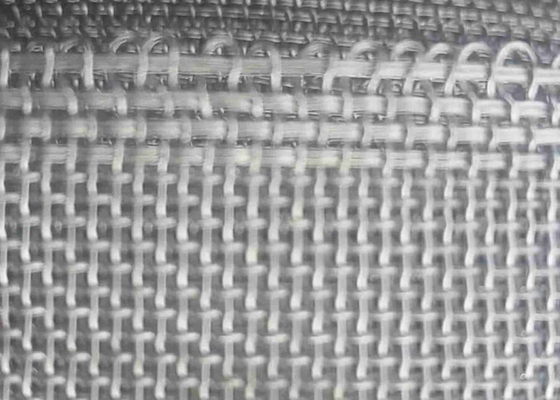

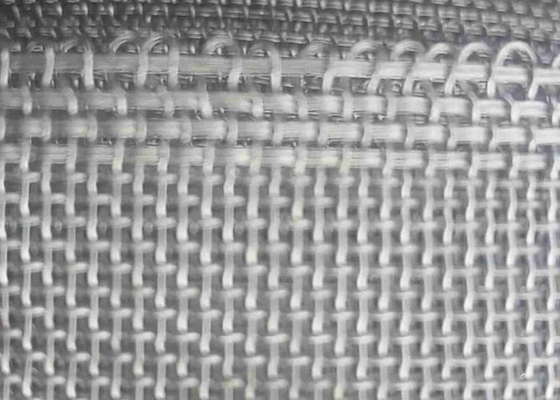

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Fecral Woven Wire Mesh With Outstanding Heating Resistance Use As Heaters And Dryers

| Features | Outstanding Heating Resistance, Oxidation Resistance Performance | Product Name | FeCrAl Woven Wire Mesh |

|---|---|---|---|

| Material | 1Cr13Al4, 1Cr12Al4, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2. | Hole Shapes | Square |

| Woven Type | Plain Weave And Twill Weave. | Mesh Counts | 8 Mesh - 80 Mesh. |

| Wire | 0.05 To 0.28mm | Common Width | 21G - 43G. |

| Common Length | 30m Or As Request | Usage | Used As Heaters And Dryers |

| Highlight | fecral metal woven wire mesh,outstanding heating resistance woven wire mesh,dryers woven wire mesh |

||

FeCrAl Woven Wire Mesh With Outstanding Heating Resistance Used As Heaters And Dryers

FeCrAl Woven Wire Mesh Introduction:

FeCrAl woven wire mesh is also called FeCrAl alloy woven wire, heating resistance alloy woven wire, electro thermal alloy mesh. The raw material is woven into a continuous meshes. Except for the FeCrAl woven wire mesh, there are FeCrAl expanded metal mesh and FeCrAl perforated mesh.

FeCrAl woven wire has outstanding heating resistance, oxidation resistance performance. It is mainly used in the industry electric furnace, household appliances. It is an ideal material for heating and drying.

Features:

Heating resistance.

Oxidation resistance.

Sulfur resistance.

Anti-carburizing.

High surface load.

Long lasting and durable.

Low temperature coefficient of resistance.

Applications:

The FeCrAl woven wire mesh is mainly used as the drying and heating equipment in metallurgy, colliery, dyeing, food factory, hospital, high density board factory and cardboard.

The FeCrAl woven wire mesh is an ideal heating resistance material in the industry electric furnace, household appliances, gas burners and infrared device.

There are still FeCrAl expanded heaters and FeCrAl perforated heaters.

Materials:

| Table 1: Chemical Compositions of L605 Wire Cloth (%) | ||||||||

| Element | C | Co | Cr | Fe | Mn | Ni | Si | W |

| Content | 0.05–0.15 | Rem. | 19–21 | 3 | 1.0–2.0 | 9.0–11.0 | 0.4 | 14.0–16.0 |

Specifications

Material: 1Cr13Al4, 1Cr12Al4, 0Cr21Al6, 0Cr25Al5, 0Cr21Al6Nb, 0Cr27Al7Mo2.

Mesh size: 8 mesh - 80 mesh.

Wire diameter: 21G - 43G.

Weaving type: plain weave and twill weave.

Max working temperature:

1Cr13Al4 - 950 degree.

1Cr21Al4 - 1100 degree.

0Cr21Al6 - 1250 degree.

0Cr23Al5 - 1250 degree.

0Cr25Al5 - 1250 degree.

0Cr21Al6Nb - 1350 degree.

0Cr27Al7Mo2 - 1400 degree.

| Mesh | Wire Gauge | Aperture (mm) | Wire Diameter (mm) | Roll Width (m) | Weight (kg/m2) |

| 8 (T) | 21 | 2.375 | 0.8 | 1 | 2.5 |

| 8 (T) | 22 | 2.475 | 0.7 | 1 | 1.84 |

| 10 (T) | 23 | 1.94 | 0.6 | 0.6 | 1.69 |

| 12 (T) | 24 | 1.557 | 0.559 | 1 | 1.8 |

| 17 (T) | 24 | 0.94 | 0.55 | 0.6 | 2.57 |

| 20 (P) | 33 | 1.02 | 0.25 | 1 | 0.587 |

| 20 (P) | 32 | 1 | 0.27 | 1 | 0.685 |

| 20 (P) | 30 | 0.97 | 0.3 | 1 | 0.846 |

| 25 (P) | 30 | 0.71 | 0.3 | 1 | 1.125 |

| 30 (P) | 38 | 0.69 | 0.15 | 1 | 0.3 |

| 34 (P) | 33 | 0.49 | 0.25 | 1 | 1.06 |

| 40 (P) | 35 | 0.425 | 0.21 | 1 | 0.83 |

| 40 (T) | 35 | 0.425 | 0.21 | 1 | 0.83 |

| 44 (T) | 35 | 0.367 | 0.21 | 1 | 0.88 |

| 60 (T) | 38 | 0.273 | 0.15 | 1 | 0.66 |

| 80 (P) | 43 | 0.227 | 0.09 | 1 | 0.324 |

Other specifications according to your request.

Packing:

![]()