-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

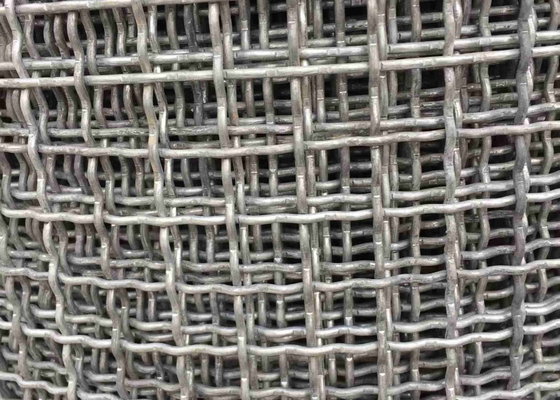

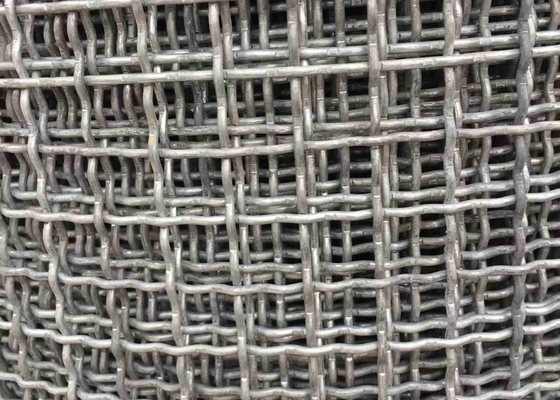

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

1 To 20 Mesh Counts Woven Crimped Wire Mesh Aluminum Alloy 1100 5056 6061

| Features | Firm Structure, Good Strength, Economy Cost | Product Name | Aluminum Crimped Mesh |

|---|---|---|---|

| Material | Aluminum Alloy 1100 5056 6061 | Type | Crimped |

| Hole Shape | Square Hole Or Slot Hole | Mesh Counts | 1 To 20 Mesh Per Inch |

| Wire Diameter | 0.2-10mm | Opening | 0.70-100 Mm |

| Rolls Or Panels | 1mX15m, 1.5mX15m, 2.0mX20m, Etc. | Application | Used As Fence Or Filters In A Lot Of Industries |

| Highlight | 1mesh woven crimped wire mesh,aluminum 1100 woven crimped wire mesh,aluminum 5056 crimped wire cloth |

||

Crimped Wire Mesh 1 To 20 Mesh Counts Aluminum Alloy 1100 5056 6061

Aluminum Crimped Wire Mesh Introduction:

Crimped Wire Mesh is made in a variety of materials through crimping mesh machine, a kind of universal wire products with square or rectangular openings. Weaving: Pre-crimping before Weaving. In two-way separated wave bending, locked bending, flat-topped curved, two-way bending, one-way separated wave bending.

It's made of aluminum alloys. Manufactured in a wide variety of wire diameters, crimped wire mesh is produced in a square or rectangular mesh. Crimped wire mesh is available in roll or flat panel form.

Specifications:

| Lock Crimp Wire Mesh | ||||

| Opening | Wire Diameter | Open Area | ||

| mm | Inch | mm | Inch | % |

| 4.0 | 0.157 | 1.0 | 0.039 | 64.00 |

| 0.8 | 0.031 | 69.44 | ||

| 5.0 | 0.197 | 1.2 | 0.047 | 65.04 |

| 1.0 | 0.039 | 69.44 | ||

| 0.8 | 0.031 | 74.32 | ||

| 6.0 | 0.236 | 2.0 | 0.079 | 56.25 |

| 1.8 | 0.071 | 59.17 | ||

| 1.6 | 0.063 | 62.33 | ||

| 1.4 | 0.055 | 65.74 | ||

| 1.2 | 0.047 | 69.44 | ||

| 1.0 | 0.039 | 73.47 | ||

| 8.0 | 0.315 | 2.0 | 0.079 | 64.00 |

| 1.8 | 0.071 | 66.64 | ||

| 1.6 | 0.063 | 69.44 | ||

| 1.4 | 0.055 | 72.43 | ||

| 1.2 | 0.047 | 75.61 | ||

| 1.0 | 0.039 | 79.01 | ||

| 10.0 | 0.394 | 2.5 | 0.098 | 64.00 |

| 2.0 | 0.079 | 69.44 | ||

| 1.8 | 0.071 | 71.82 | ||

| 1.6 | 0.063 | 74.32 | ||

| 1.5 | 0.059 | 75.61 | ||

| 1.4 | 0.055 | 76.95 | ||

| 1.2 | 0.047 | 79.72 | ||

| 1.0 | 0.039 | 82.64 | ||

| 12.0 | 0.472 | 4.0 | 0.157 | 56.25 |

| 3.5 | 0.138 | 59.93 | ||

| 2.6 | 0.102 | 67.55 | ||

| 1.5 | 0.059 | 79.01 | ||

| 12.7 | 1/2” | 4.0 | 0.157 | 57.83 |

| 3.5 | 0.138 | 61.46 | ||

| 3.0 | 0.118 | 65.43 | ||

| 2.5 | 0.098 | 69.81 | ||

| 2.0 | 0.079 | 74.64 | ||

| 1.8 | 0.071 | 76.71 | ||

| 15.0 | 0.591 | 4.8 | 0.189 | 57.39 |

| 4.5 | 0.177 | 59.17 | ||

| 4.0 | 0.157 | 62.33 | ||

| 3.5 | 0.138 | 65.74 | ||

| 3.0 | 0.118 | 69.44 | ||

| 2.6 | 0.102 | 72.63 | ||

| 2.5 | 0.098 | 73.47 | ||

| 2.0 | 0.079 | 77.85 | ||

| 19.0 | 0.748 | 4.8 | 0.189 | 63.73 |

| 4.0 | 0.157 | 68.24 | ||

| 3.5 | 0.138 | 71.30 | ||

| 20.0 | 0.787 | 4.8 | 0.189 | 65.04 |

| 4.5 | 0.177 | 66.64 | ||

| 4.0 | 0.157 | 69.44 | ||

| 3.5 | 0.138 | 72.43 | ||

| 3.0 | 0.118 | 75.61 | ||

| 2.5 | 0.098 | 79.01 | ||

| 2.0 | 0.079 | 82.64 | ||

| 25.0 | 0.984 | 4.8 | 0.189 | 70.37 |

| 3.5 | 0.138 | 76.94 | ||

| 3.0 | 0.118 | 79.71 | ||

| 2.0 | 0.079 | 85.73 | ||

| 25.4 | 1” | 4.8 | 0.189 | 70.74 |

| 4.5 | 0.177 | 72.16 | ||

| 4.0 | 0.157 | 74.64 | ||

| 3.5 | 0.138 | 77.25 | ||

| 3.0 | 0.118 | 79.99 | ||

| 2.5 | 0.098 | 82.88 | ||

| 30.0 | 1.181 | 4.8 | 0.189 | 74.32 |

| 4.5 | 0.177 | 75.61 | ||

| 4.0 | 0.157 | 77.85 | ||

| 3.5 | 0.138 | 80.20 | ||

| 3.0 | 0.118 | 82.64 | ||

| 2.5 | 0.098 | 85.21 | ||

| 38.1 | 1-1/2” | 4.8 | 0.189 | 78.87 |

| 4.5 | 0.177 | 79.99 | ||

| 4.0 | 0.157 | 71.90 | ||

| 3.5 | 0.138 | 83.88 | ||

| 3.0 | 0.118 | 85.93 | ||

| 2.5 | 0.098 | 88.06 | ||

| 50.8 | 2” | 4.8 | 0.189 | 83.48 |

| 4.5 | 0.177 | 84.39 | ||

| 4.0 | 0.157 | 85.93 | ||

| 3.5 | 0.138 | 87.52 | ||

| 3.0 | 0.118 | 89.16 | ||

| 70.0 | 2.756 | 4.8 | 0.189 | 87.58 |

| 76.2 | 3” | 4.8 | 0.189 | 88.50 |

| 4.5 | 0.177 | 89.16 | ||

| 4.0 | 0.157 | 90.27 | ||

| 3.5 | 0.138 | 91.41 | ||

| 88.9 | 3-1/2” | 3.5 | 0.138 | 92.57 |

| 101.6 | 4” | 4.8 | 0.189 | 91.18 |

Other sizes as your special request.

Aluminum Alloys:

These are light metals, with good strength to weight ratios. At ordinary

temperatures they resist Nitric and Sulphuric Acids, but corrode quickly in the presence of alkaline solutions and hydrochloric and hydrofluoric acids. Melts at 1218 F.

| Alloy | Al | Cu | Fe | Mg | Mn | Si | Zn | Cr |

| 1100 | ≥99.0 | 0.2 | 0.06 | - | 0.05 | 0.04 | 0.1 | - |

| 5056 | 93.0-94.5 | 0.1 | 0.4 | 4.5-5.6 | 0.05-0.2 | 0.3 | 0.1 | 0.05-0.2 |

| 6061 | 96.0-97.0 | 0.15-0.4 | 0.7 | 0.8-1.2 | 0.15 | 0.4-0.8 | 0.25 | 0.15-0.35 |

Features:

Firm structure;

Accurate & uniform apertures;

Good strength;

Economy cost;

High temperature resisting;

Acid resisting;

Alkali resisting;

Corrosion resisting, etc.

Applicatioins:

Agricultural

Architectural & Artistic

Building & Construction

Cabinetry & Furniture

Cages & Enclosures

Fan Guards

Filtration & Particle Separation Disks

Fireplace Screen

Fuel Industries

Heat Treatment

Hydraulic Applications

Railing & Guardrail Infill Panels

Mining & Quarrying

Oil Strainers

ety Fencing & Machine Guards

Security & Prison

Window Guards

Wine Lockers

![]()

Packing:

in waterproof paper and film, then in pallets. Custom packing available at request.

![]()

![]()