-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

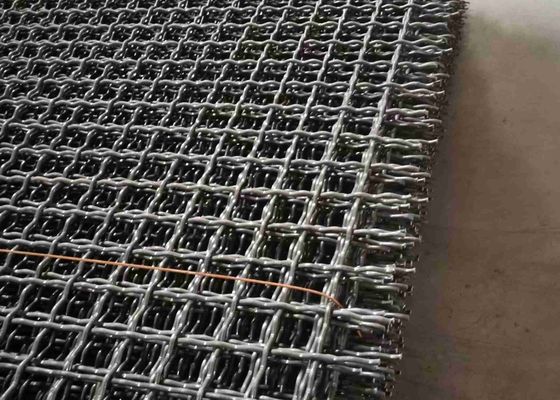

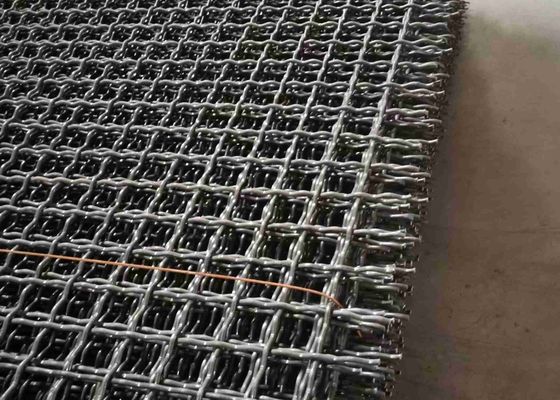

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

0.6 To 5.8mm Stainless Steel Wire Net 5 To 100mm Opening SS316

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Intercrimped Assure The Proper Locking Of The Warp And Weft Wires | Product Name | Intermediate Crimped Wire Mesh |

|---|---|---|---|

| Material | Stainless Steel | Crimped Type | Intermediate Crimped Mesh |

| Surface | Bright Silver | Opening | 5mm To 100mm |

| Wire Diameter | 0.6mm To 8.8mm | Width | 1m To 4m |

| Length | 15m To 60m | Applications | Architectural And Decorative Industries, Petrochemical, Chemical Industries, Etc |

| Highlight | 5.8mm Stainless Steel Wire Net,5.8mm 0.6mm Stainless Steel Wire Net,5.8mm SS316 stainless steel net mesh |

||

Intermediate Crimped 5 to 100mm Opening 0.6 to 5.8mm Wire Stainless Steel Crimped Wire Mesh

Intermediate Crimped Wire Mesh Introduction:

Inter-crimp refers to the use of extra crimps between intersections to provide rigidity and locking tightness for light wires in relationship to the wire opening. This type of construction allows for rectangular and square openings in a large variety of sizes.

Intermediate crimped can be divided into single intermediate crimped and double intermediate crimped. The single intermediate crimped means the weft wire is pre-crimped and the warp wire is directly woven. The double intermediate crimped means both the weft wire and warp wire is pre-crimped and then woven together.

Pre-crimped process: Using the precision machine, the intermediate crimped wire is pre-crimped by the rotary dies. The pre-crimped wire can assure the spacing of the wires. When the wires are woven together, the structure can ensure the wires will lock firmly together at the intersections.

Specifications:

Opening Sizes: from 4mm to 100mm.

Wire Diameters: from 0.8mm to 4.8mm.

Roll Width: 1m, 1.22m, 1.5m to 4m.

Roll Length: 15m, 30m to 60m.

Panel Width: 0.5m, 0.914m, 1m, 1.22m to 2m.

Panel Length: 1m, 1.22m, 1.5m to 6m.

| Intermediate Crimped Wire Mesh | ||||

| Opening | Wire Diameter | Open Area | ||

| mm | Inch | mm | Inch | % |

| 5.0 | 0.197 | 1.0 | 0.039 | 69.44 |

| 0.9 | 0.053 | 71.82 | ||

| 0.8 | 0.031 | 74.32 | ||

| 0.7 | 0.028 | 76.95 | ||

| 0.6 | 0.024 | 79.72 | ||

| 6.0 | 0.236 | 1.0 | 0.039 | 73.47 |

| 0.8 | 0.031 | 77.85 | ||

| 0.6 | 0.024 | 82.64 | ||

| 7.0 | 0.276 | 1.4 | 0.055 | 69.44 |

| 1.2 | 0.047 | 72.87 | ||

| 1.0 | 0.039 | 76.56 | ||

| 0.8 | 0.031 | 80.54 | ||

| 8.0 | 0.315 | 4.0 | 0.157 | 44.44 |

| 1.6 | 0.063 | 69.44 | ||

| 1.4 | 0.055 | 72.43 | ||

| 1.2 | 0.047 | 75.61 | ||

| 1.0 | 0.039 | 79.01 | ||

| 0.8 | 0.031 | 82.64 | ||

| 10.0 | 0.394 | 2.0 | 0.079 | 69.44 |

| 1.8 | 0.071 | 71.82 | ||

| 1.6 | 0.063 | 74.32 | ||

| 1.4 | 0.055 | 76.95 | ||

| 1.2 | 0.047 | 79.72 | ||

| 1.0 | 0.039 | 82.64 | ||

| 12.0 | 0.472 | 2.0 | 0.079 | 73.46 |

| 12.7 | 1/2” | 2.6 | 0.102 | 68.90 |

| 2.3 | 0.091 | 71.68 | ||

| 2.0 | 0.079 | 74.64 | ||

| 1.8 | 0.071 | 76.71 | ||

| 1.6 | 0.063 | 78.87 | ||

| 1.4 | 0.055 | 81.13 | ||

| 1.2 | 0.047 | 83.48 | ||

| 15.0 | 0.591 | 3.0 | 0.118 | 69.44 |

| 2.5 | 0.098 | 73.47 | ||

| 2.0 | 0.079 | 77.85 | ||

| 16.0 | 0.630 | 3.0 | 0.118 | 70.91 |

| 20.0 | 0.787 | 4.0 | 0.157 | 69.44 |

| 3.6 | 0.142 | 71.82 | ||

| 3.2 | 0.126 | 74.32 | ||

| 3.0 | 0.118 | 75.61 | ||

| 2.9 | 0.114 | 76.26 | ||

| 2.6 | 0.102 | 78.31 | ||

| 2.5 | 0.098 | 79.01 | ||

| 2.3 | 0.091 | 80.44 | ||

| 2.0 | 0.079 | 82.64 | ||

| 1.8 | 0.071 | 84.17 | ||

| 25.0 | 0.984 | 4.0 | 0.157 | 74.31 |

| 3.5 | 0.138 | 76.94 | ||

| 3.0 | 0.118 | 79.71 | ||

| 2.5 | 0.098 | 82.64 | ||

| 25.4 | 1” | 4.8 | 0.189 | 70.74 |

| 4.4 | 0.173 | 72.65 | ||

| 4.0 | 0.157 | 74.64 | ||

| 3.6 | 0.142 | 76.71 | ||

| 3.2 | 0.126 | 78.87 | ||

| 2.9 | 0.114 | 80.56 | ||

| 2.6 | 0.102 | 82.29 | ||

| 2.3 | 0.091 | 84.08 | ||

| 2.0 | 0.079 | 85.93 | ||

| 30.0 | 1.181 | 5.0 | 0.197 | 73.46 |

| 4.0 | 0.157 | 77.85 | ||

| 3.5 | 0.138 | 80.19 | ||

| 3.0 | 0.118 | 82.64 | ||

| 2.5 | 0.098 | 85.20 | ||

| 35.0 | 1.378 | 4.0 | 0.157 | 80.53 |

| 38.1 | 1-1/2” | 5.8 | 0.228 | 75.32 |

| 5.3 | 0.209 | 77.07 | ||

| 4.8 | 0.189 | 78.87 | ||

| 4.4 | 0.173 | 80.37 | ||

| 4.0 | 0.157 | 81.09 | ||

| 3.6 | 0.142 | 83.48 | ||

| 3.2 | 0.126 | 85.10 | ||

| 2.9 | 0.114 | 86.35 | ||

| 2.6 | 0.102 | 87.63 | ||

| 40.0 | 1.575 | 5.0 | 0.197 | 79.01 |

| 4.0 | 0.157 | 82.64 | ||

| 3.0 | 0.118 | 86.53 | ||

| 2.5 | 0.098 | 88.58 | ||

| 50.0 | 1.969 | 5.0 | 0.197 | 82.64 |

| 4.0 | 0.157 | 85.73 | ||

| 3.0 | 0.118 | 88.99 | ||

| 50.8 | 2” | 5.8 | 0.228 | 80.56 |

| 5.3 | 0.209 | 82.00 | ||

| 4.8 | 0.189 | 83.48 | ||

| 4.4 | 0.173 | 84.69 | ||

| 4.0 | 0.157 | 85.93 | ||

| 3.6 | 0.142 | 87.20 | ||

| 3.2 | 0.126 | 88.50 | ||

| 2.9 | 0.114 | 89.49 | ||

| 60.0 | 2.362 | 5.0 | 0.197 | 85.20 |

| 4.0 | 0.157 | 87.89 | ||

| 63.5 | 2-1/2” | 5.8 | 0.228 | 83.96 |

| 5.3 | 0.209 | 85.19 | ||

| 4.8 | 0.189 | 86.44 | ||

| 4.4 | 0.173 | 87.46 | ||

| 4.0 | 0.157 | 88.50 | ||

| 75.0 | 2.953 | 5.0 | 0.197 | 87.89 |

| 76.2 | 3” | 5.8 | 0.228 | 86.35 |

| 5.3 | 0.209 | 87.42 | ||

| 4.8 | 0.189 | 88.50 | ||

| 88.9 | 3-1/2” | 5.8 | 0.228 | 88.13 |

| 5.3 | 0.209 | 89.06 | ||

| 100.0 | 3.937 | 5.0 | 0.197 | 90.70 |

| 101.6 | 4” | 5.8 | 0.228 | 89.49 |

| 5.3 | 0.209 | 90.33 | ||

Other Specifications according to your requirements.

![]()

Weave Patterns:

![]()

Material:

Standard materials of flat top crimped wire mesh are low/mild/high carbon steel and stainless steel 201, 202, 304, 316, 321, 410, 430.

Following material available:

Copper: brass, pure copper, phosphor bronze

Aluminum: 1050, 1060, 1100, 5052, 5056

Nickel: pure nickel, nickel alloy, monel

Features:

Intercrimped assure the proper locking of the warp and weft wires;

Superior rigidity and greater stability;

Strong wear resistance and firm structure.

Usage:

Architectural & decorative industries, for the screen of window, fireplace, fence and ceiling.

Agricultural & food industries, for barbecue grills.

Mining & aggregate industries, for the screens of vibrating machine.

Automobile industries, for radiator grills and headlight covers.

Petrochemical & chemical industries, for test sieve.

Packing:

Crimped wire mesh is packed in rolls, wrapped in moisture-proof paper or plastic film, outside wooden cases or wooden pallet.

![]()