-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

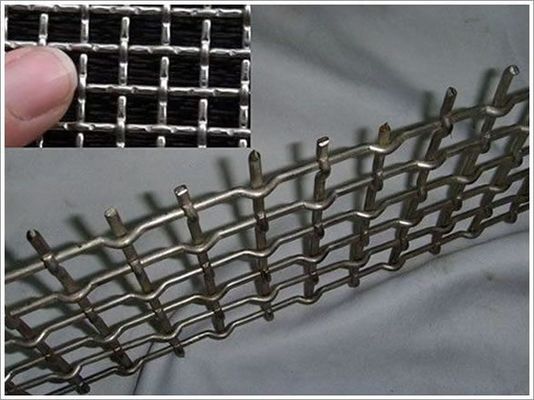

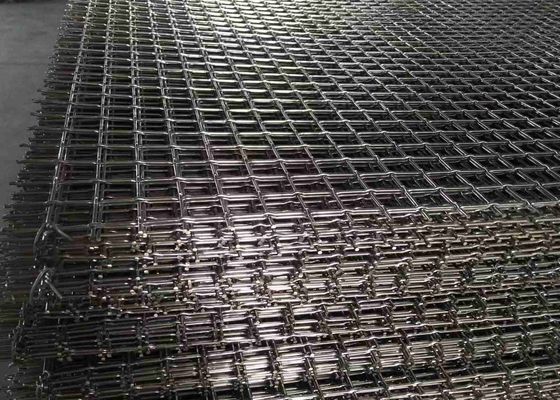

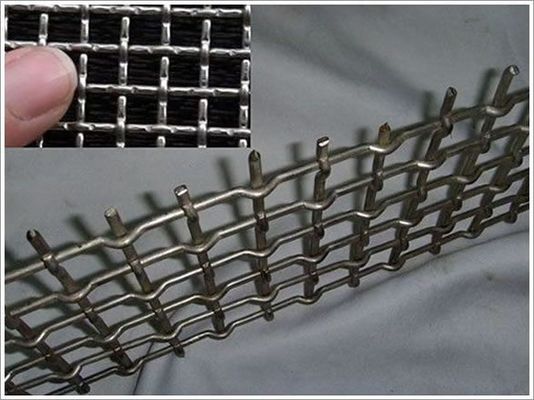

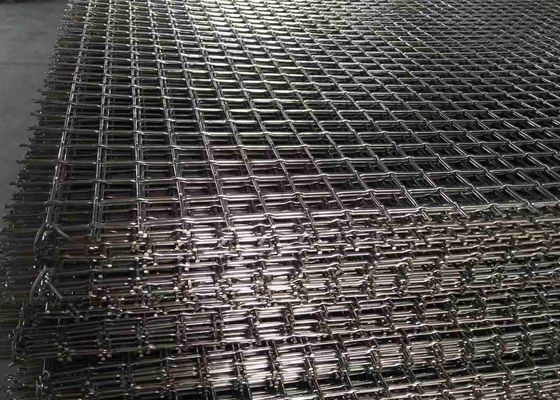

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Plain Crimped 8" Carbon Steel Wire Mesh For Mining And Quarry

| Product Nmae | Crimped Wire Mesh | Material | High Carbon Steel |

|---|---|---|---|

| Standard | ASTM | Technique | Pre- Crimped |

| Aperture | UP To 8" | Length | 30m Or Customized |

| Width | 1m, 1.2m, 2m Or Customized | Advantage | Rust Resistance, Etc |

| Application | Fence, Mining, Etc | ||

| Highlight | 8in Carbon Steel Wire Mesh,Crimped Carbon Steel Wire Mesh,Plain crimped woven wire mesh |

||

High Carbon Steel Plain Crimped For Mining And Quarry Crimped Wire Mesh

High Carbon Steel Wire Mesh

High Carbon Steel Wire Mesh is specially made for various applications such as separating, filtering, grading, sizing, crushing and shifting of different construction materials. Its rigid design with excellent resistance against abrasions make the wire mesh ideal for screening of various products and sizing or processing heavy abrasive materials like ores, crushed stones, sand and gravel coal. Available in different sizes and lengths, these wire mesh screens can meet the most demanding requirements of industries.

65Mn steel wire for wire media

65 Mn wire media is made from high tensile temper 65 Mn steel, best material for screen mesh in china. Mn-steel wedge wire is used of embedded (Mn65-Q) method of weaving. Warp and weft point is not outstanding, the surface is smooth, even by force. 65 Mn steel screen mesh has high quality ductility and toughness. When with the strong shock friction, the surface will have a strong work-hardening due to the plastic deformation. And the surface hardness can be increased to more than HRC60 so that it can obtain the high wear resistance. While the infernal remains high plasticity and toughness. When the old surface of the wear and tear, the new surface will form a wear-resistant layer with a long life.

65 Mn wire media can be woven by plain weave,double crimped weave,flat top weave etc. It is widely used for screening all kinds size of sand, gravel, coal, stone,rock, chipping, metal material and other ore material in mining, quarry and aggregate industries. Our company provides variety of mn steel screen mesh to meet customer's special application.

Specifications:

|

Material

|

65Mn steel wire / high carbon steel wire / wire diameter tolerance< 0.03mm

|

|

Aperture tolerance

|

+/-3%

|

|

Length and Width

|

<-5mm

|

|

Consistent quality of wire

|

DIN 17223/A

|

|

Flat surface

|

1/4opg max/48'' never more than 1/4 aperture

|

|

Screen squareness tolerance

|

< 1.5mm/ 300mm' length

|

|

Standard wire diameter

|

1.5mm to 16mm

|

| aperture square weave |

Medium | Heavy Duty | ||||

|---|---|---|---|---|---|---|

| Wire Dia |

kg/m² | OA% |

Wire |

kg/m² | OA% | |

| 2.00 | 1.37 | 7.1 | 35 | |||

| 3.15 | 2.00 | 9.9 | 37 | 2.50 | 14.1 | 31 |

| 4.0 | 2.50 | 12.2 | 38 | 3.05 | 16.8 | 32 |

| 5.0 | 2.50 | 16.6 | 44 | 3.05 | 14.7 | 38 |

| 5.6 | 3.05 | 13.7 | 41 | 4.00 | 21.2 | 34 |

| 6.35 | 3.05 | 12.6 | 46 | 4.00 | 19.6 | 38 |

| 6.8 | 3.05 | 10.0 | 44 | 4.00 | 19.7 | 37 |

| 7.1 | 3.05 | 11.9 | 48 | 4.00 | 18.3 | 41 |

| 8 | 4.00 | 16.9 | 44 | 5.00 | 24.4 | 38 |

| 9 | 4.00 | 15.6 | 48 | 5.00 | 22.7 | 44 |

| 10 | 4.00 | 14.5 | 51 | 5.00 | 21.2 | 44 |

| 11.2 | 5.00 | 19.6 | 48 | 5.60 | 28.6 | 44 |

| 12.5 | 5.00 | 18.1 | 51 | 5.60 | 20.0 | 47 |

| 14 | 5.00 | 20.0 | 51 | 6.80 | 24.6 | 48 |

| 16 | 5.60 | 19.5 | 56 | 6.80 | 22.6 | 51 |

| 18 | 6.80 | 20.7 | 55 | 7.10 | 25.0 | 51 |

| 20 | 6.80 | 19.2 | 58 | 7.10 | 24.0 | 54 |

| 22 | 7.10 | 21.5 | 57 | 8.00 | 26.7 | 54 |

| 25 | 7.10 | 20.1 | 60 | 8.00 | 24.6 | 57 |

| 28 | 8.00 | 19.0 | 61 | 9.00 | 27.8 | 57 |

| 32 | 9.00 | 26.0 | 60 | 10.00 | 30.4 | 58 |

| 38 | 9.00 | 28.1 | 64 | 10.00 | 27.9 | 61 |

| 40 | 10.00 | 25.4 | 64 | 11.20 | 31.1 | 61 |

| 45 | 10.00 | 23.4 | 67 | 11.20 | 28.4 | 64 |

| 50 | 11.20 | 26.0 | 67 | 12.50 | 31.8 | 64 |

| 56 | 11.20 | 28.7 | 69 | 12.50 | 29.0 | 67 |

| 63 | 11.20 | 24.5 | 72 | 12.50 | 25.1 | 70 |

| 76.2 | 11.20 | 16.0 | 75 | 12.50 | 20.0 | 73 |

| 80 | 11.20 | 17.5 | 72 | 12.50 | 21.5 | 75 |

| 90 | 11.20 | 15.7 | 79 | 12.70 | 19.4 | 77 |

| 100 | 11.20 | 14.3 | 81 | 12.70 | 17.6 | 79 |

Carbon Steel Parameter

| N0 | Grade | Chemical Composition% | ||

|---|---|---|---|---|

| C | Si | Mn | ||

| 1 | 45 | 0.42-0.50 | 0.17-0.37 | 0.50-0.80 |

| 2 | 50 | 0.47-0.55 | ||

| 3 | 55 | 0.52-0.60 | ||

| 4 | 60 | 0.57-0.65 | ||

| 5 | 65 | 0.62-0.70 | ||

| 6 | 70 | 0.67-0.75 | ||

| 7 | 65Mn | 0.62-0.70 | 0.90-1.20 | |

| 8 | 72A | 0.70-0.75 | 0.15-0.35 | 0.30-0.60 |

Hook type Crimped wire mesh product details:

![]()

![]()

Features:

Highly resistant to abrasions and wear & tear

High tensile strength

Light weight

Rigid construction

Resistance against corrosion

Portability

Ability to withstand extreme temperature

Applications:

Mines & quarry

Coal mines

Foundries

Heat treatment

Waste management

Water treatment industry

Construction industry

Cement industry

Metallurgy industry

Ceramic industry

Food processing industry

Agriculture industry

![]()

Packing:

![]()