-

SS Welded Wire Mesh

-

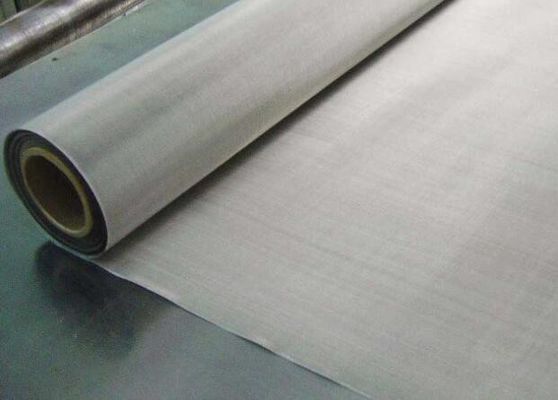

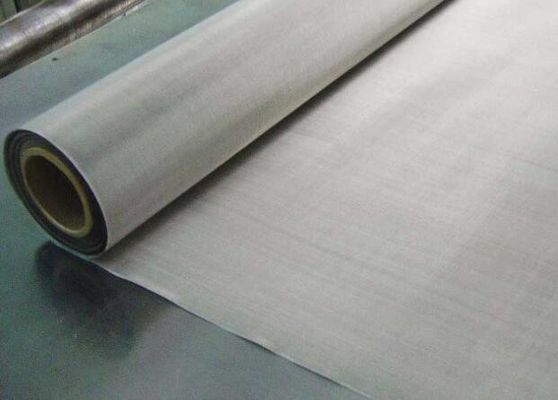

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

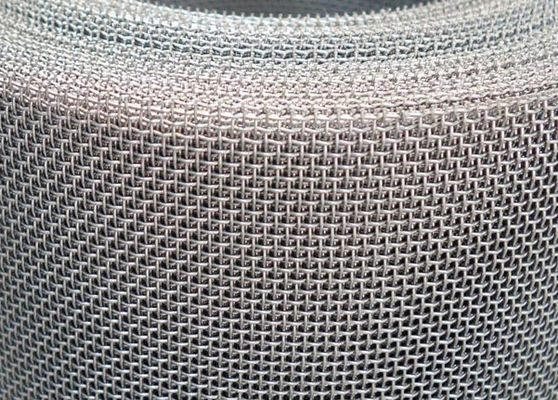

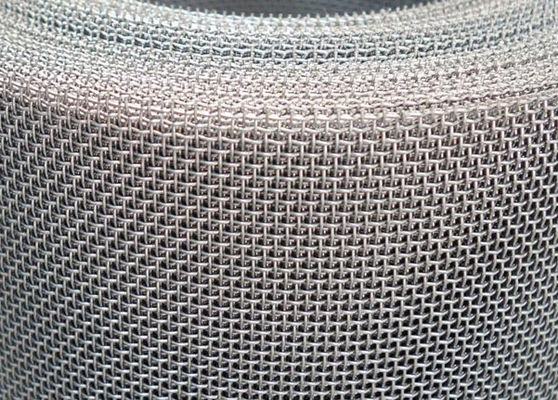

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Hastelloy C-22 Metal Wire Mesh 0.5 To 200 Mesh Twill Weave

| Features | Excellent Resistance To Oxidizing Aqueous Media | Product Name | Hastelloy C- 22 Wire Mesh |

|---|---|---|---|

| Material | Hastelloy C22 | Standard | ASTM |

| Hole Shapes | Square | Woven Type | Plain Weave, Twill Weave |

| Mesh Counts | 0.5 To 200 | Roll Length | 30m |

| Roll Width | 0.5m - 3.0m | Usages | Pharmaceutical Industries |

| Highlight | Hastelloy C-22 metal wire mesh,0.5 Mesh metal wire mesh,200 Mesh weave wire mesh |

||

Hastelloy C- 22 Wire Mesh 0.5 To 200 per inch Excellent resistance to oxidizing aqueous media

Hastelloy C22 Wire Mesh Introduction:

Hastelloy C22 Wire Mesh Screen is a versatile austenitic nickel-chromium-molybdenum-tungsten alloy with enhanced resistance to pitting, crevice corrosion and stress corrosion cracking. The high chromium content provides good resistance to oxidizing media while the molybdenum and tungsten content give good resistance to reducing media. This nickel steel alloy also has excellent resistance to oxidizing aqueous media including wet chlorine and mixtures containing nitric acid or oxidizing acids with chlorine ions. Other corrosives Hastelloy C-22 Wire Mesh Screen has resistance to are oxidizing acid chlorides, wet chlorine, formic and acetic acids, ferric and cupric chlorides, sea water, brine and many mixed or contaminated chemical solutions, both organic and inorganic. This nickel alloy also offers optimum resistance to environments where reducing and oxidizing conditions are encountered in process streams. This is beneficial in multi- purpose plants where such "upset" conditions occur frequently.

This nickel alloy resists the formation of grain-boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in the as-welded condition.

Attention Please:

Alloy C-22 Wire Mesh Screen should not be used in service temperatures above 1250° F (676.7℃) due to the formation of detrimental phases which form above this temperature.

Features:

1) Resistant to pitting, crevice corrosion and stress corrosion cracking

2) Outstanding resistance to both reducing and oxidizing media

3) Excellent resistance to oxidizing aqueous media

4) Exceptional resistance to a wide variety of chemical process environments including strong oxidizers such as ferric acids, acetic anhydride, and seawater and brine solutions

5) Resists the formation of grain-boundary precipitates in the weld heat-affected zone

6) Excellent weldability

Application:

Main Specs:

| Mesh/Inch |

Wire Dia (mm) |

Mesh Opening(mm) | Open Area(%) |

| 4 | 1.60 | 4.75 | 56% |

| 8 | 1.19 | 1.98 | 39% |

| 8 | 0.120 | 0.303 | 51% |

| 10 | 0.89 | 1.65 | 42% |

| 16 | 0.51 | 1.09 | 46% |

| 20 | 0.41 | 0.86 | 46% |

| 40 | 0.25 | 0.385 | 37% |

| 80 | 0.12 | 0.197 | 38% |

| 200 | 0.05 | 0.077 | 37% |

| 325 | 0.035 | 0.043 | 30% |

![]()

Packing:

Inside with a paper core, outside with a piece of waterproof, the in wooden case.