-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

Rectangle Oval Shaped Extruder Screens Good Rust Corrosion Resistance

| Place of Origin | Anping of China |

|---|---|

| Brand Name | QIANPU |

| Certification | ISO |

| Minimum Order Quantity | 1000Pieces |

| Price | Negotiable according to quantity of order |

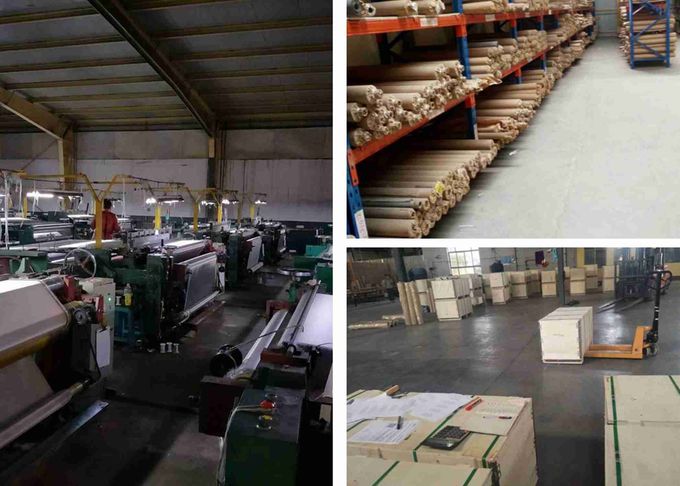

| Packaging Details | 1. inside use carton pipe for support+wire mesh layer+water proof paper 2. outside use plastic wooden bags+wooden case/carton pipes/wooden pallets. 3. also we can as per your requirements. |

| Delivery Time | 2 weeks |

| Payment Terms | T/T, Western Union, L/C |

| Supply Ability | 3000 rolls per month |

| Features | Flexible, Used In Extrusion Process Or Filtration Process. | Product Name | Rectangle And Oval-Shaped Extruder Screens |

|---|---|---|---|

| Material | Stainless Steel, Brass, Aluminum. | Processing | Woven, Sintered, Perforated |

| Technique | Plain Weave, Plain Dutch Weave Or Twilled Weave. | Layer | Single Layer Or Multilayer Cylindrical |

| Size | Can Be Customized. | Useage | Petrochemical, Pharmaceutical Rubber And Plastic Industries In Film Coating, Lamination And Filtration Process |

| Highlight | Corrosion Resistance Extruder Screens,Rectangle Extruder Screens,Oval-Shaped Extruder Screens |

||

Rectangle And Oval-Shaped Extruder Screens Has Good Rust And Corrosion Resistance

Introduction

Rectangle and oval-shaped extruder screens are commonly made from stainless steel wire that has good rust and corrosion resistance. Of course, they can be made from aluminum, low carbon steel or copper according to application needs.

With special and stable structure, rectangle and oval-shaped extruder screens possess accurate sizes and are applied to fine filtration in non-woven fabrics, color masterbatch, filler and fibers extruder industries.

Spot Welded Extruder Screen Packs:

This extruder screen packs are excellent used in all the extrusion and filtration process and assembled in reasonable sequence to assure the best application. The number and location of spot welds can be designed according to your special process.

Framed Extruder Screen Packs:

This kind of screen pack is firstly spot welded and then have an aluminum or stainless steel edge which can give the extruder screen pack extra rigidity and strength. So it can bear more weight than spot welded packs.

Features:

Accurate shape dimension well fit the corresponding extruder.

Easy to install and durable.

High compressive strength.

Applications:

Provide a clean and fine extrusion of molten materials, polymers.

Suitable for filtration in plastic, leather, metallurgy and petroleum industries.

Specificationis:

Materials: stainless steel, aluminum, low carbon steel, brass.

Sizes: can be customized.

Processing: woven, sintered, perforated.

Layer: single layer, multiple layers.

Edge: spot welding, metal or rubber rims, no frame.

| Mesh | Wire Dia. mm | Aperture Size | Open Area % |

| 10 × 10 | 0.711 | 1.829 mm | 51.8 |

| 14 × 14 | 0.457 | 1.357 mm | 55.9 |

| 16 × 16 | 0.457 | 1.131 mm | 50.7 |

| 20 × 20 | 0.559 | 0.711 mm | 31.4 |

| 20 × 20 | 0.457 | 0.813 mm | 41 |

| 24 × 24 | 0.376 | 0.682 mm | 41.4 |

| 30 × 30 | 0.376 | 0.531 mm | 34.2 |

| 30 × 30 | 0.31 | 0.536 mm | 40 |

| 40 × 40 | 0.274 | 0.361 mm | 32.3 |

| 50 × 50 | 0.193 | 0.335 mm | 43.6 |

| 60 × 60 | 0.193 | 0.230 mm | 29.8 |

| 80 × 80 | 0.122 | 0.196 mm | 37.9 |

| 100 × 100 | 0.102 | 0.152 mm | 36 |

| 120 × 120 | 0.091 | 0.120 mm | 31.8 |

| 150 × 150 | 0.071 | 0.088 mm | 29.6 |

| 200 × 200 | 0.05 | 0.077 mm | 36.76 |

| 250 × 250 | 0.04 | 0.062 mm | 36.76 |

| 300 × 300 | 0.04 | 0.045mm | 27.83 |

| 325 × 325 | 0.035 | 0.043mm | 30.49 |

| 400 × 400 | 0.028 | 0.036mm | 31.25 |

| 500 × 500 | 0.025 | 0.026mm | 25.79 |

![]()

Packing:

Questions: What specs are needed to quote?

Answer: Material, woven type, aperture or mesh counts, wire diameter, roll width x roll length and number of rolls.