-

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

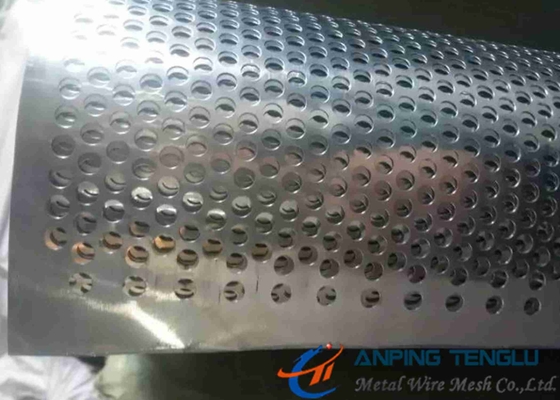

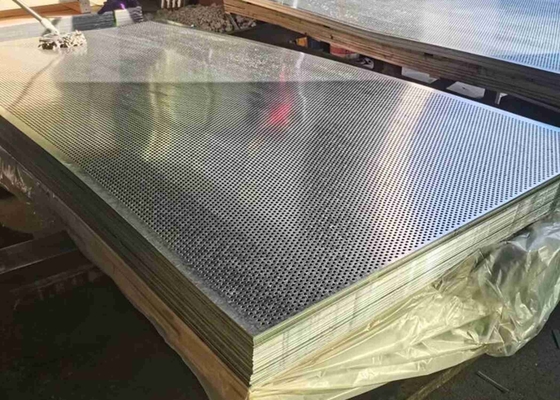

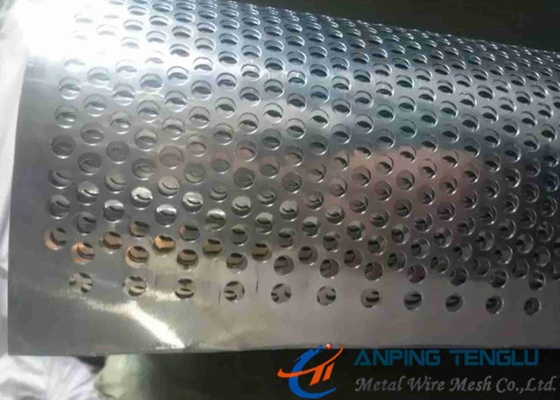

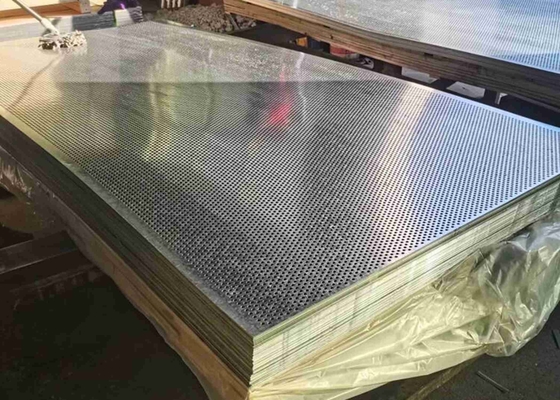

Wear Resisting 0.5mm Perforated Metal Mesh Stainless Steel S30400

| Features | Has Good Corrosion Resistance, High Temperature Resistance | Product Name | Stainless Steel Perforated Mesh |

|---|---|---|---|

| Material | Stainless Steel | Hole Shape | Round, Slot, Square, Hexagnoal, Etc |

| Punched | Perforated | Thickness | 0.5mm To 8.0mm |

| Hole Pattern | 90°, 45°, 60° | Width | 1m, 1.22m, 1.5m To 4m |

| Length | 15m, 30m To 60m | Application | Architecture, Chemical Industry, Filter, Etc |

| Highlight | s30400 perforated metal mesh,0.5mm perforated metal mesh,wear resisting perforated metal wire mesh |

||

Stainless Steel Perforated Mesh With Good Wear Resisting Perforated Metal Mesh

Stainless Steel Perforated Mesh Introduction:

Stainless steel perforated metal mesh has good corrosion resistant performance in air, steam, water and other weak corrosive medium. It has high strength and wear resistance, which supports the longer service life than mild steel.

Among all the materials, stainless steel is the most economical one and you can find it widely used in our life.

Material:

304 (S30400) – It has high temperature resistance, good processability and high hardness. It is widely used in industry, medical treatment, food, architecture and other industries.

304L (S30403) – It is a kind of extra-low-carbon stainless steel of 304. It reduces carbon deposition during welding. In addition, its welding property is higher than 304.

316 (S31600) – A certain amount of Mo elements are added in 316, which can improve the resistance against high temperature, corrosion and wear. It is widely used in marine works, chemical industry, medical treatment, construction and other industries.

316L (S31603) – It is a kind of extra-low-carbon stainless steel of 316. It reduces carbon deposition during welding. In addition, its welding property is higher than 316.

321 (S32100) – A certain amount of Ti elements are added in 321. It can maintain the stability under the condition of severe corrosion. It is highly corrosion resistant, high temperature resistant, wear resistant and creep resistant. It is widely used in oil, chemical, medical treatment, aircraft and other industries.

430 (S43000) – 430 stainless steel has better thermal conductivity and corrosion resistant performance than 300 series. 430 stainless steel can resist the corrosion of nitric acid and some organic acids. It is widely used in chemical, laboratory and other corrosive environments.

|

Chemical Component (%)

|

|||||||||||

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Others | |

| 304 | min. | – | – | – | – | – | 17.5 | – | 8 | – | – |

| max. | 0.07 | 2 | 0.75 | 0.045 | 0.03 | 19.5 | – | 10 | 0.1 | – | |

| 304L | min. | – | – | – | – | – | 17.5 | – | 8 | – | – |

| max. | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 19.5 | – | 10 | 0.1 | – | |

| 316 | min. | – | – | – | – | – | 16 | 2 | 10 | – | – |

| max. | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | – | |

| 316L | min. | – | – | – | – | – | 16 | 2 | 10 | – | – |

| max. | 0.03 | 2 | 0.75 | 0.045 | 0.03 | 18 | 3 | 14 | 0.1 | – | |

| 321 | min. | – | – | – | – | – | 17 | – | 9 | – | Ti = 5 (C + N) |

| max. | 0.08 | 2 | 0.75 | 0.045 | 0.03 | 19 | – | 12 | 0.1 | 0.7 | |

| 430 | min. | – | – | – | – | – | 16 | – | – | – | – |

| max. | 0.12 | 1 | 1 | 0.04 | 0.03 | 18 | – | 0.75 | – | – | |

|

Mechanical Property

|

|||||

| Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break in 50 mm (%) | Hardness | |

| min. | min. | min. | Rockwell Hardness | Brinell Hardness (HB) max. | |

| 304 | 515 | 205 | 40 | 92 | 201 |

| 304L | 485 | 170 | 40 | 92 | 201 |

| 306 | 515 | 205 | 40 | 95 | 217 |

| 306L | 485 | 170 | 40 | 95 | 217 |

| 321 | 515 | 205 | 40 | 95 | 217 |

| 430 | 450 | 205 | 22 | 89 | 183 |

Parts of Specifications:

| Hole Diameter | Staggered Centers | Sheet Thickness | Open Area | ||

| 0.045" | 1.14mm | 0.66" | 0.033-0.039" | 0.84-0.99mm | 37% |

| 1/16" | 1.59mm | 3/32" | 0.027-0.033" | 0.68-0.84mm | 41% |

| 1/16" | 1.59mm | 1/8" | 0.027-0.066" | 0.68-1.68mm | 23% |

| 5/64" | 1.98mm | 1/8" | 0.027-0.053" | 0.68-1.35mm | 35% |

| 0.081" | 2.06mm | 1/8" | 0.053-0.066" | 1.35-1.68mm | 38% |

| 3/32" | 2.38mm | 5/32" | 0.053*0.066" | 1.35-1.68mm | 33% |

| 1/8" | 3.17mm | 3/16" | 0.027-0.127" | 0.68-3.23mm | 40% |

| 5/32" | 3.97mm | 3/16" | 0.027-0.056" | 0.68-1.68mm | 63% |

| 3/16" | 4.76mm | 1/4" | 0.027-0.127" | 0.68-3.23mm | 50% |

| 1/4" | 6.35mm | 3/8" | 0.033-0.011",0.25" | 0.84-2.82mm,6.35mm | 40% |

| 3/8" | 9.52mm | 1/2" | 0.053-0.082",3/16" | 1.35-2.08mm,4.76mm | 51% |

| 3/8" | 9.52mm | 9/16" | 0.059",0.119" | 1.5mm,3.02mm | 40% |

| 1/2" | 12.7mm | 11/16" | 0.033-0.127",3/16" | 0.84-3.23mm,4.76mm | 48% |

| 1/4" Hex | 6.35mm | 0.285" | 0.027-0.033" | 0.68-0.84mm | 76% |

| 3/8" Sq | 9.52mm | Cane" | 0.053-0.066" | 1.35-1.68mm | 51% |

Other Specifications according to your requirements.

Features:

has good corrosion resistant performance in air, steam, water and other weak corrosive medium. It has high strength and wear resistance, which supports the longer service life than mild steel.

Hole Patterns including:

Round; Rectangular hole; Square; Triangle; Diamond; Slotted Hole; Hexagonal; Cross; Slotted; and other patterns according to your drawings or application requirement.

![]()

![]()

![]()

Applications:

Architecture

Chemical industry.

Paper industry.

Pharmaceutical industry.

Automotive & Transport.

Filter

Furniture

Decorative

Speaker Grille

![]()

Packing:

![]()

![]()

Our Perforated Metal Mesh List:

Round hole perforated sheet

Square hole perforated sheet

Slot hole perforated sheet

Decorative Perforated Sheet

Embossed sheet

Perforated steel sheet

Perforated stainless steel sheet

Perforated aluminum sheet

perforated copper or brass sheet

Etched plates

Perforated metal noise barrier

Perforated filter form SS, carbon steel, aluminum, or copper sheet

Perforated tube

Perforated sunshade panel

Perforated kinetic facade

Anti-skid stair steps

Hexagonal hole perforated metal

Louver hole perforated metal

Raised Perforated Metal

Nickel perforated metal

Galvanized perforated metal

Carbon steel perforated metal

Perforated metal for filter

Perforated Metal for facade