-

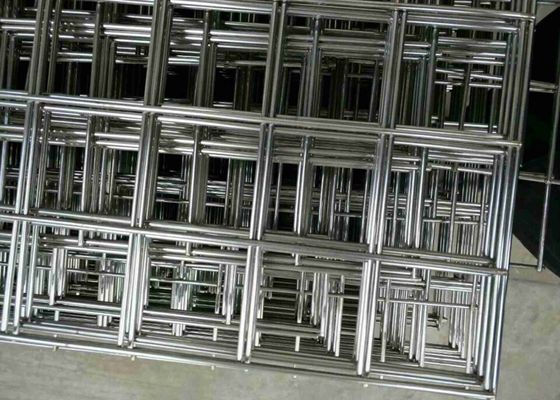

SS Welded Wire Mesh

-

SS Woven Wire Mesh

-

Stainless Steel Dutch Wire Mesh

-

Stainless Steel Crimped Wire Mesh

-

Stainless Steel Knitted Wire Mesh

-

Stainless Steel Security Screen Mesh

-

Stainless Steel Wire Coil

-

Metal Woven Wire Mesh

-

Expanded Metal Mesh

-

Perforated Metal Mesh

-

Wire Mesh Filters

-

Wire Conveyor Belt

-

Decorative Metal Mesh

-

Sintered Wire Mesh

-

Metal Wire Mesh Fence

-

JoelThank you, thank you again for your excellent customer service.

JoelThank you, thank you again for your excellent customer service.

904L 0.25" To 8" SS Welded Wire Mesh Corrosion Resistance

| Place of Origin | Anping of China |

|---|---|

| Brand Name | QIANPU |

| Certification | ISO |

| Minimum Order Quantity | 50 Panels |

| Price | Negotiable |

| Packaging Details | Inside with a paper tube, outside with plastic film or waterproof paper, then in wooden case or pallets. |

| Delivery Time | 20 days |

| Payment Terms | T/T, Western Union, L/C |

| Features | Super Excellent Corrosion Resistance | Product Name | SS904L Welded Mesh |

|---|---|---|---|

| Material | 904L | Standard | AISI, DIN |

| Type | Welded | Hole Shape | Square Or Rectangle |

| Surface Treament | Polished | Opening Size | 1/4" To 8" |

| Width | 0.6m, 1m, 1.2m, 1.8m, 2m, 2.5m | Application | Aerospace, Filtration, Etc |

| Highlight | 8" SS Welded Wire Mesh,0.25'' SS Welded Wire Mesh,904L stainless steel welded wire |

||

904L Mesh In Welded Structure Super Excellent Corrosion Resistance SS Welded Wire Mesh

904L Stainless Steel Wire Mesh

904L stainless steel is a low carbon, high nickel and molybdenum austenitic stainless steel. 904L stainless steel wire mesh contains 21% chromium, 25.5% nickel, 4.5% molybdenum and 1.5% copper. It is ideal for a variety of different environments, including inorganic acid and organic acid environments. In a neutral medium chlorine ion environment, has excellent pitting corrosion resistance. The high content of chromium, nickel and molybdenum (the content of nickel and molybdenum is almost twice as that of 316L) gives it superior corrosion resistance, better high-temperature oxidation resistance, and further enhances its resistance to pitting and crevice corrosion. The addition of copper makes it suitable for all concentrations of sulfuric acid.

904L stainless steel wire mesh is available in welded structure as well. It displays super excellent corrosion resistance in severe industrial and chemical settings. It is primarily used in the filtration of industry, chemical/ petrochemical, food processing industry (especially for pickled food). The following gives more industries it served.

Material: 904L

| 904L Chemical Composition % | ||||||||||

| Type | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| 904L | ≤0.02 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.030 | 19.0-23.0 | 23.0-28.0 | 4.0-5.0 | ≤0.10 | 1.0-2.0 |

Specifications:

| Opening Size | Wire Diameter | ||

| Inch | mm | SWG | mm |

| 1/4" × 1/4" | 6.4 mm × 6.4 mm | 22# - 24# | 0.6 mm - 0.7 mm |

| 3/8" × 3/8" | 10.6 mm × 10.6 mm | 19# - 22# | 0.7 mm - 1.0 mm |

| 1/2" × 1/2" | 12.7 mm × 12.7 mm | 16# - 23# | 0.6 mm - 1.6 mm |

| 5/8" × 5/8" | 16 mm × 16 mm | 18# - 21# | 0.8 mm - 1.2 mm |

| 3/4" × 3/4" | 19.1 mm × 19.1 mm | 16# - 21# | 0.8 mm - 1.6 mm |

| 1" × 1/2" | 25.4 mm × 12.7 mm | 16# - 20# | 0.9 mm - 1.6 mm |

| 1" × 1" | 25.4 mm × 25.4 mm | 14# - 21# | 0.8 mm - 1.2 mm |

| 1 1/2" × 1 1/2" | 38 mm × 38 mm | 14# - 19# | 1.0 mm - 2.0 mm |

| 1" × 2" | 25.4 mm × 50.8 mm | 14# - 16# | 1.6 mm - 2.0 mm |

| 2" × 2" | 50.8 mm × 50.8 mm | 12# - 16# | 1.6 mm - 2.6 mm |

| 2" × 3" | 50 mm × 75 mm | 13# - 16# | 1.6 mm - 2.3 mm |

| 3" × 3" | 75 mm × 75 mm | 12# - 16# | 1.6 mm - 2.6 mm |

| 2" × 4" | 50 mm × 100 mm | 13# - 14# | 2.0 mm - 2.3 mm |

| 4" × 4" | 100 mm × 100 mm | 13# - 14# | 2.0 mm - 2.3 mm |

| 8" × 8" | 200 mm × 200 mm | 13# - 14# | 2.0 mm - 2.3 mm |

Other sizes as your special request.

Hole Opening: Min1/4" to Max 8"

![]()

![]()

Features:

It is ideal for a variety of different environments, including inorganic acid and organic acid environments. In a neutral medium chlorine ion environment, has excellent pitting corrosion resistance. The high content of chromium, nickel and molybdenum (the content of nickel and molybdenum is almost twice as that of 316L) gives it superior corrosion resistance, better high-temperature oxidation resistance, and further enhances its resistance to pitting and crevice corrosion. The addition of copper makes it suitable for all concentrations of sulfuric acid.

Applicatioins:

Architectural

Marine application

High Chloride environment

Filtration/Sieving

Wastewater treatment

![]()

Packing:

Each roll with polyfilm with water proof paper, outside wooden pallets.

![]()

![]()